MCU as the core component of IOT, developed rapidly in recent years.

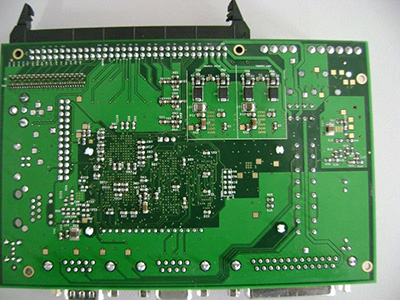

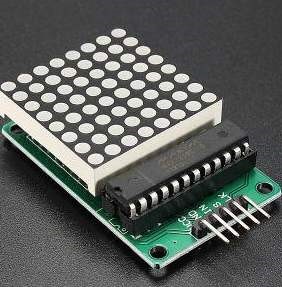

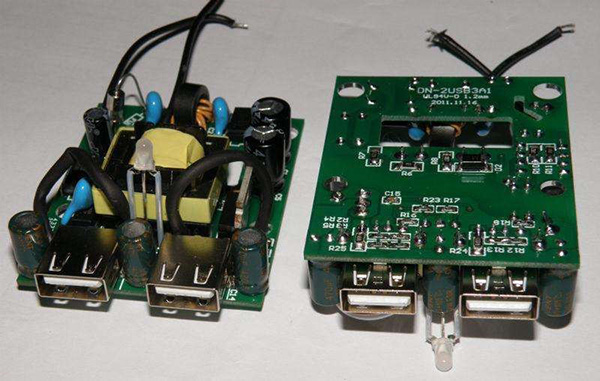

MCU control board, with full name of Micro Controller Unit, can combine a micro controller-based chip, other electronic components and an integrated PCB to control external circuits. Based on the characteristics of industrial measurement and control objects, environment, and interface, MCU control board is moving towards the function of making money control, improving the reliability in the industrial environment, and forming the interface interface of the application computer system flexibly and conveniently.

The application of MCU control boards:

Usually it is used in some simple industrial control, such as measuring & controlling system, smart meter, mechatronics products, smart interface, etc. And MCU could also be used in smart civilian products, such as household appliances, toys, game consoles, audiovisual equipment, electronic scales, cash registers, office equipment, kitchen equipment, etc. The introduction of MCU not only greatly enhances the functions of the products, improves performance, but also achieves Use effect.

The principle of MCU control boards:

It is more economical to use C language or other control languages to write control action processes to achieve the ultimate purpose of industrial control.

The capacity of MCU:

Base Material: FR-4

Copper Thickness: 17.5um-175um (0.5oz-5oz)

Board Thickness: 0.21mm ~ 7.0mm

Min. Hole Size: 0.10mm

Min. Line Width: 3mil

Min. Line Spacing: 3 Mil (0.075 Mm)

Surface Finishing: HASL

Layers: 1 ~ 32 layers

Hole tolerance: PTH:±0.076mm, NTPH:±0.05mm

Solder mask Color: Green/White/Black/Red/Yellow/Blue

Silkscreen Color: White/Black/Yellow/Blue

Reference Standard: IPC-A-600G Class 2, Class 3

The differences between MCU and PLD:

(1) MCU controls the peripheral devices to work by changing the level of the I / O port through a program; PLD is to change the internal structure of the chip through programming.

(2) MCU is a chip, but it cannot be used directly; PLC has ready-made interface, it is very convenient and reliable to directly use in the industrial scene, and then connect to the man-machine interface for direct control.

(3) MCU chip is cheap, and is used for automatic control of batch products in manufacturing industry; PLC is suitable for industrial automatic control.