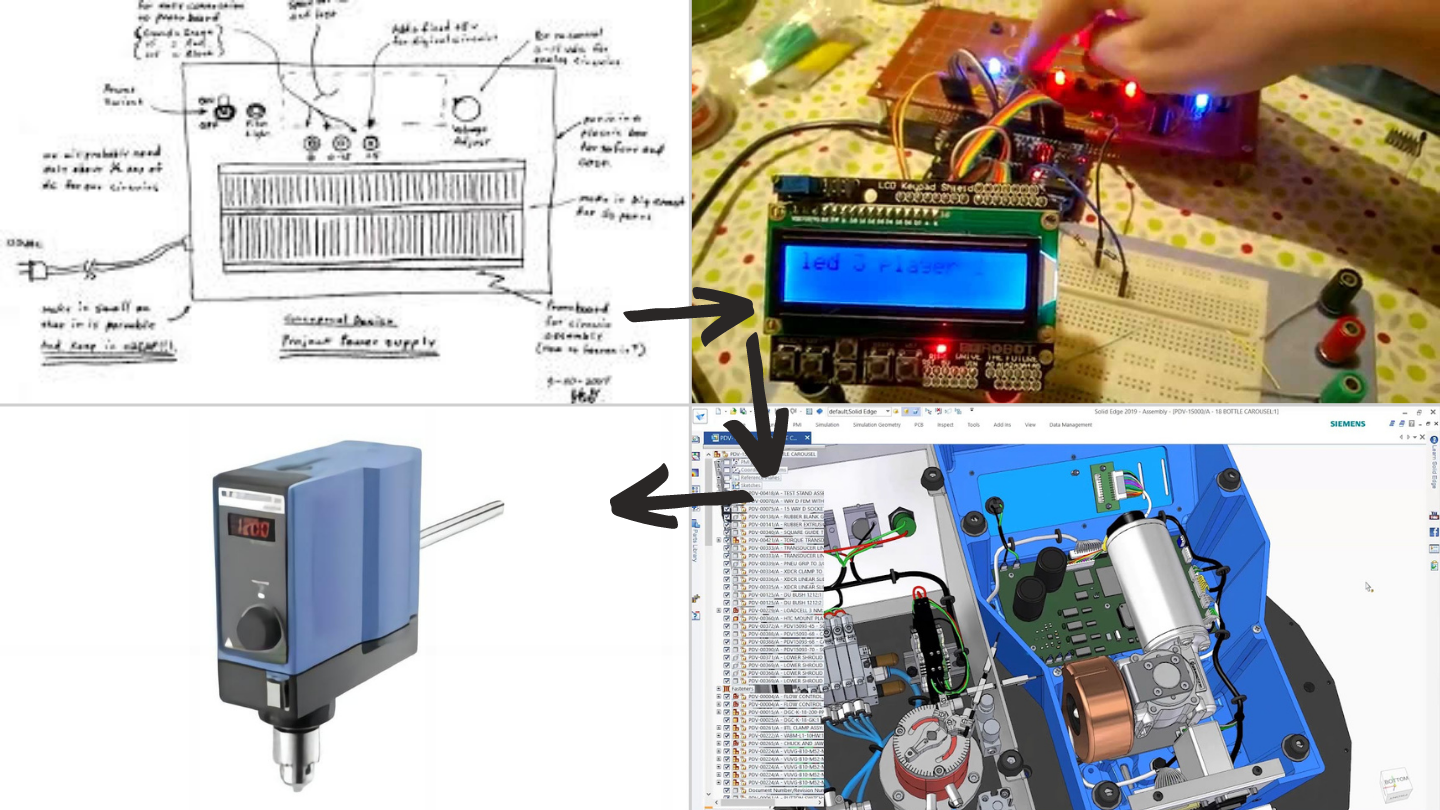

Fumax Tech offers a wide variety of mechanical engineering design services. We can create the complete mechanical design for your new product, or we can make modifications and improvements to your existing mechanical design. We can satisfy your mechanical design needs with a team of highly skilled mechanical engineers and designers having extensive experience in new product development. Our mechanical design contract engineering experience is with a variety of product categories, including consumer products, medical devices, industrial products, , communications products, transportation products and other products

We have state-of-the-art 3D CAD systems for mechanical design, as well as a variety of tools / equipment for mechanical analysis and testing. Our combination of experienced engineers and design tools allows Fumax Tech to deliver you a mechanical design optimized for functionality and manufacturability.

Typical software tool: Pro-E, solid Works.

File format: step

Our mechanical development process typically involves the following steps:

1. Requirements

We work together with our client to determine the mechanical requirements for the specific product or system. The requirements include size, features, operation, performance, and durability.

2. Industrial Design (ID)

The external appearance and style for the product is defined, including any buttons and displays. This step is done in parallel with the development of the mechanical architecture.

3. Mechanical architecture

We develop the high level mechanical structure for the product(s). The number and type of mechanical parts are defined, as well as the interface to the Printed Circuit Boards and other parts of the product.

4. Mechanical CAD layout

We create the detailed mechanical design of each of the individual mechanical parts in the product. The 3D MCAD layout integrates all of the mechanical parts as well as the electronic subassemblies in the product.

5. Prototype assembly

After we complete the mechanical layout, mechanical prototype parts are fabricated. The parts allow verification of the mechanical design, and these parts are combined with the electronics to make working prototypes of the product. We provide quick 3D print or CNC Samples as quick as 3 days.

6. Mechanical testing

The mechanical parts and working prototypes are tested to verify that they meet the applicable requirements. Agency compliance testing is performed.

7. Production support

After a mechanical design has been fully tested, we will create a mechanical design release for Fumax tooling/moulding engineers to fabricate the mould, to further production. We build tooling / mould in house.