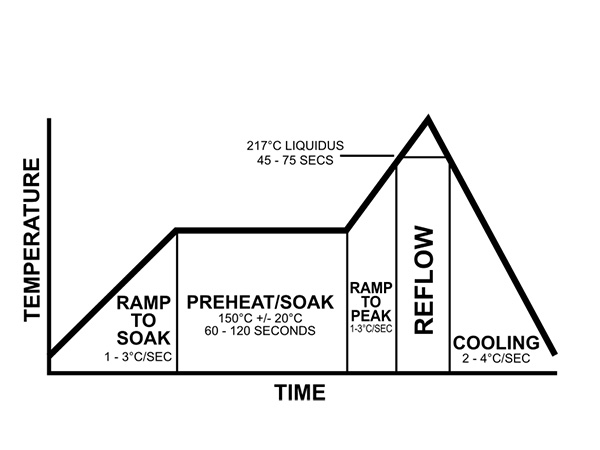

Reflow Soldering process is an important process to get good solder quality. Fumax reflow soldering machine has 10 temp. zone. We calibrate temp. on a daily basis to ensure correct temp.

Reflow soldering refers to control the heating to melt the solder to achieve permanent bonding between electronic components and circuit board. There are different reheating methods for soldering, such as reflow ovens, infrared heating lamps or hot air guns.

In recent years, with the development of electronic products in the direction of small size, light weigh and high density, reflow soldering has to face big challenges. Reflow soldering is required to adopt more advanced heat transfer methods to achieve energy saving, temperature uniforming, and suitable for increasingly complex requirements of the soldering.

1. Advantage:

(1) Large temperature gradient, easy to control temperature curve.

(2) The solder paste can be distributed accurately, with less heating times and less possibility to be mixed with impurities.

(3) Suitable for soldering all kinds of high-precision and high-demand components.

(4) Simple process and high soldering quality.

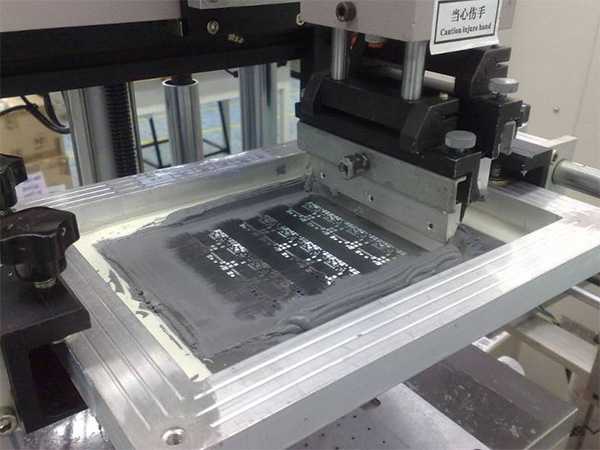

2. Production preparing

First, the solder paste is accurately printed on each board through a solder paste mold.

Second, the component is placed on the board by SMT machine.

Only after these preparations are fully prepared, does the real reflow soldering begin.

3. Application

Reflow soldering is suitable for SMT, and works with SMT machine. When components are attached to the circuit board, the soldering needs to be completed by reflow heating.

4. Our capacity: 4 Sets

Brand:JTTEA 10000/AS-1000-1/SALAMANDER

Lead-free

5. Contrast between wave soldering & reflow soldering:

(1)Reflow soldering is mainly used for chip components; Wave soldering is mainly for soldering plug-ins.

(2)Reflow soldering already has solder in front of the furnace, and only the solder paste is melted in the furnace to form a solder joint; Wave soldering is done without solder in front of the furnace, and soldered in the furnace.

(3)Reflow soldering: high temperature air forms reflow soldering to components; Wave soldering: Molten solder forms wave soldering to components.