Fumax SMT production has deployed automatic SPI machine to check the solder paste printing quality, to ensure best soldering quality.

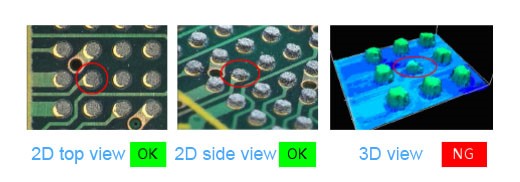

SPI, known as solder paste inspection, an SMT testing device that uses the principle of optics to calculate the solder paste height printed on the PCB by triangulation. It is the quality inspection of solder printing and the verification and control of printing processes.

1. The function of SPI:

Discover the shortcomings of print quality in time.

SPI can intuitively tell users which solder paste prints are good and which are not good, and provides points of which kind of defect it belongs to.

SPI is to detect a series of solder paste to find the quality trend, and find out the potential factors that cause this trend before the quality exceeds the range, for example, the printing machine’s control parameters, human factors, solder paste change factors, etc. Then we could adjust in time to control the continued spread of the trend.

2. What to be detected:

Height, volume, area, position misalignment, diffusion, missing, breakage, height deviation (tip)

3. The difference between SPI & AOI:

(1) Following solder paste printing and before SMT machine, SPI is used to achieve the quality inspection of solder printing and the verification and control of printing process parameters, through a solder paste inspection machine (with a laser device that can detect the thickness of the solder paste) .

(2) Following SMT machine, AOI is the inspection of component placement(before reflow soldering) and the inspection of solder joints(after reflow soldering).