The IPC (Association Connecting Electronics Industries) is a global trade association that develops standards for the electronics manufacturing industry. These standards are crucial for ensuring quality, reliability, and consistency in the production of printed circuit boards (PCBs) and their assembly. This article will cover the main IPC standards relevant to PCB manufacturing and assembly, detail their specific requirements, and discuss their applicability to various industries and products.

Key IPC Standards for PCB Manufacturing and Assembly

IPC-A-600: Acceptability of Printed Boards

IPC-A-600 is one of the most widely recognized standards for the acceptability of printed boards. It provides comprehensive visual and text descriptions of the various types of acceptable and non-acceptable conditions for PCBs.

- Key Details:

- Classification: Divides products into three classes based on end-use and performance criteria:

- Class 1: General Electronic Products (e.g., consumer electronics)

- Class 2: Dedicated Service Electronic Products (e.g., computers, communication equipment)

- Class 3: High-Reliability Electronic Products (e.g., military, aerospace)

- Classification: Divides products into three classes based on end-use and performance criteria:

- Requirements:

- Defect Criteria: Clear definitions of acceptable and non-acceptable defects.

- Inspection: Guidelines for visual inspection of the boards.

IPC-A-610: Acceptability of Electronic Assemblies

IPC-A-610 is a critical standard for the acceptability of electronic assemblies. It focuses on ensuring high-quality workmanship and the reliability of electronic products.

- Key Details:

- Classification: Same three-class system as IPC-A-600.

- Requirements:

- Soldering: Criteria for solder joint acceptability, including lead-free solder.

- Component Mounting: Specifications for the correct placement and securing of components.

- Cleanliness: Requirements for the cleanliness of assemblies post-manufacture.

- Coating: Standards for conformal coatings applied to protect assemblies.

IPC-6012: Qualification and Performance Specification for Rigid Printed Boards

IPC-6012 specifies the performance and qualification requirements for rigid printed boards.

- Key Details:

- Classification: Uses the same class system as IPC-A-600 and IPC-A-610.

- Requirements:

- Material Properties: Specifications for materials used in rigid PCBs.

- Electrical Properties: Requirements for the electrical performance of PCBs.

- Dimensional Criteria: Tolerances for board dimensions and hole sizes.

IPC-620: Requirements and Acceptance for Cable and Wire Harness Assemblies

IPC-620 provides the criteria for cable and wire harness assemblies, ensuring they meet high-quality and reliability standards.

- Key Details:

- Classification: Adopts the same three-class system.

- Requirements:

- Wire Preparation: Standards for wire stripping and tinning.

- Connector Assembly: Criteria for the correct attachment of connectors.

- Soldering and Crimping: Acceptability standards for solder and crimp connections.

IPC-2221: Generic Standard on Printed Board Design

IPC-2221 offers guidelines for the design of printed boards and other forms of component mounting or interconnecting structures.

- Key Details:

- Design Considerations: Includes aspects like material selection, mechanical and electrical considerations, and thermal management.

- Requirements:

- Layout: Guidelines for component placement and routing.

- Signal Integrity: Design considerations for maintaining signal integrity.

Applicability of IPC Standards Across Industries

Consumer Electronics

Standards like IPC-A-600 and IPC-A-610 are essential for consumer electronics, where reliability is important, but not as critical as in other sectors. Class 1 and Class 2 specifications are typically sufficient.

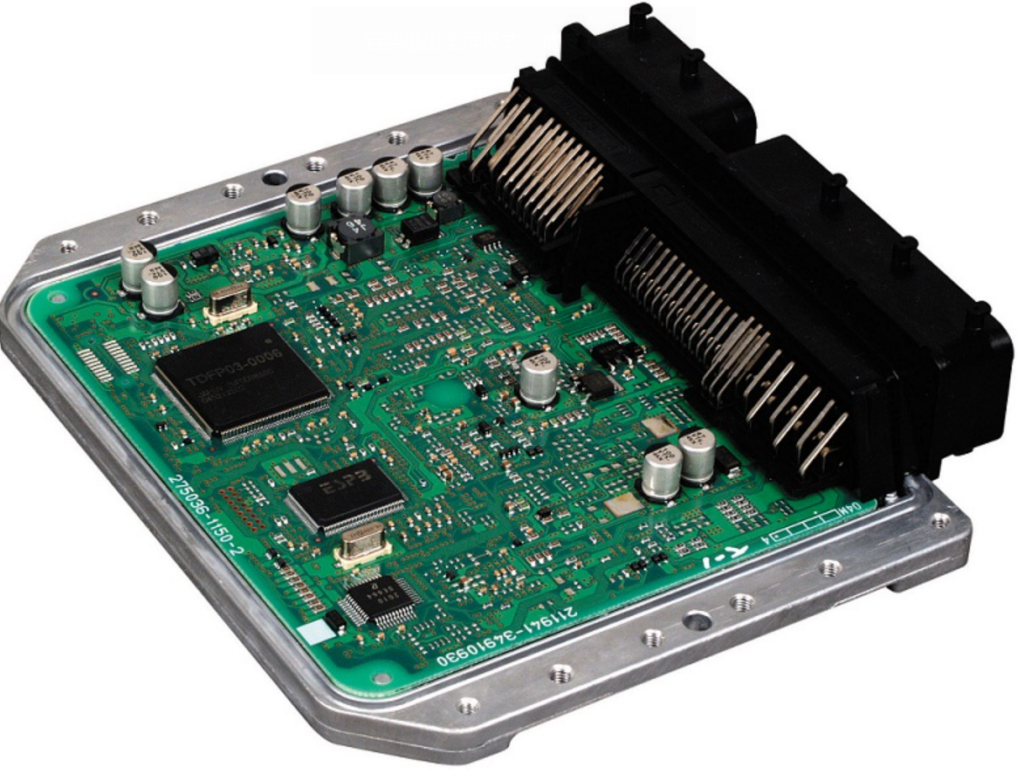

Automotive

The automotive industry often requires Class 2 or Class 3 standards due to the need for higher reliability and durability in harsh environments. Standards such as IPC-6012 and IPC-2221 are critical for ensuring robust design and manufacturing processes.

Aerospace and Military

For aerospace and military applications, the highest level of reliability is required. These sectors primarily use Class 3 standards across all relevant IPC standards, including IPC-A-600, IPC-A-610, and IPC-6012, to ensure the utmost quality and performance.

Medical Devices

Medical devices also demand high reliability and performance, typically adhering to Class 3 standards. IPC-A-610 and IPC-6012 are particularly relevant, ensuring that medical devices function correctly and safely.

Conclusion

IPC standards are fundamental to the PCB manufacturing and assembly industry, providing detailed guidelines to ensure quality, reliability, and consistency. By adhering to these standards, manufacturers can meet the specific requirements of various industries, from consumer electronics to high-reliability sectors like aerospace, military, and medical devices. Understanding and implementing these standards is crucial for producing high-quality electronic products that meet the rigorous demands of today’s technology landscape.

4o