At Fumax, we pride ourselves on delivering specialized and customized services, providing high-quality electronics manufacturing solutions. Our meticulously designed project tracking process ensures seamless coordination at every step, meeting all customer requirements. Here’s an in-depth look at our comprehensive project tracking process:

1. Pre-Production Confirmation

After the customer confirms the contract, our sales representatives will resend all relevant production documents via email for customer verification. This step includes but is not limited to:

- PCBA BOM (Bill of Materials): A detailed list of all electronic components and their specifications to ensure accuracy and consistency.

- Gerber Files: Detailed PCB design information for precise manufacturing.

- Parts List: A comprehensive list of all accessories, including connectors and cables, ensuring completeness.

- Labeling Requirements: Clear instructions on label content and placement for easy product identification.

- Enclosure/Structural Material and Production Requirements: Detailed descriptions of the materials, colors, and manufacturing processes for enclosures and structural components to meet customer specifications.

- Firmware and related Testing procedure: In new projects, it is common to debug firmware multiple times as the development progresses. Make sure we use the correct version number for this production

This pre-production confirmation step ensures the customer verifies all production details, avoiding any errors or deviations during manufacturing.

2. Production Tracking and Information Synchronization

Before mass production of a new project, we typically produce 2-3 pre-production samples for customer approval. These samples are presented to the customer through:

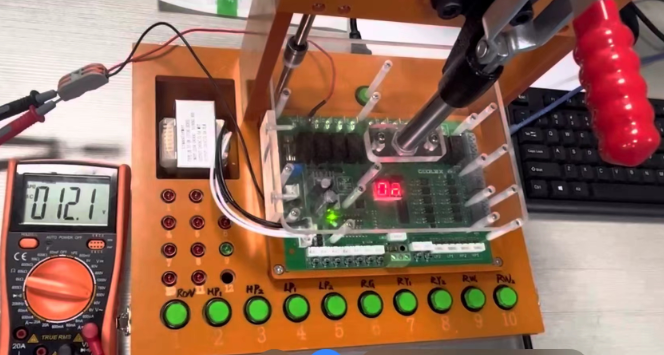

- Photo Display: Detailed images of the samples’ appearance and details, ensuring customer satisfaction with the product’s look, and all components/accessories attached as required.

- Video Demonstration: Videos showcasing the samples’ functions and operations if necessary, ensuring customer satisfaction with the product’s performance.

Once the customer approves the samples, mass production will strictly follow the sample specifications, ensuring consistency.

If material substitutions are needed during production, we notify the customer via email, providing the new material specifications and reasons for the change (e.g., to shorten lead times). All substitutions must be approved by the customer via email, ensuring full transparency and customer awareness of any changes.

We maintain close communication with customers through regular update emails or conference calls, ensuring production progress and quality are always under customer control.

3. Pre-Shipping Confirmation

After production, our sales representatives send an email detailing the production results, including:

- Production Quantity: The specific number of units ready for shipment, ensuring clarity on delivery quantities.

- Product Photos: Images of the finished products, ensuring customer satisfaction with the appearance.

- Function Demonstration Videos: Product functionality videos as per customer requirements, ensuring customer satisfaction with performance.

If the customer has special packaging requirements, we confirm the packaging plan with the customer at this stage to ensure it meets both parties’ agreements.

We also conduct a thorough quality check on all products to ensure they are defect-free and meet all customer specifications.

4. Pre-Shipping Confirmation

This step typically coincides with pre-shipping confirmation. Our sales representatives inform the customer of the remaining balance and shipping costs, providing related packing lists and invoices. Customers can choose to have Fumax handle the shipping or use their own preferred shipping services. This flexibility ensures customers can select the most suitable logistics solution for their needs.

We also provide a detailed logistics plan, including estimated shipping times and potential delays, ensuring customers have a clear understanding of the shipping process.

5. Shipping Follow-Up

Upon receiving full payment, the finance department authorizes the warehouse to ship the products. Our sales representatives assist with handling import and export customs clearance, ensuring smooth delivery to the customer. Our shipping follow-up services include:

- Logistics Information Synchronization: Real-time tracking of logistics information, ensuring customers are always updated on the shipment status.

- Customs Clearance Support: Providing necessary customs clearance documents and support, ensuring smooth passage through customs.

We also follow up with the customer after delivery to gather feedback and ensure satisfaction with the received products. If customers encounter any issues or need further support, our team responds promptly.

Differentiated and Professional Services

Fumax’s project tracking process is not only orderly at every stage but also reflects differentiated and professional service quality. We excel in the following areas:

- Customized Confirmation: We provide detailed production document verification services based on customer-specific requirements, ensuring every detail meets customer expectations.

- Efficient Communication: We use various methods, including photos and videos, to showcase samples and production results, ensuring customers are always updated on the project’s progress.

- Flexible Response: When material changes are necessary, we provide detailed reasons and specifications for the changes, ensuring all adjustments are approved by the customer.

- Professional Follow-Up: From pre-production to shipping, each step is managed by dedicated personnel, ensuring smooth project execution.

Our team excels in both technical expertise and dedicated service, ensuring every project is completed smoothly and exceeds customer expectations.

Conclusion

Fumax is committed to providing high-quality customized electronics manufacturing services. Through our professional project tracking process and differentiated services, we ensure every project is completed smoothly and exceeds customer expectations. We look forward to partnering with you to create a brighter future.

Whether you need large-scale production or small-batch customization, Fumax offers the best solutions. Contact us to learn more about our services and let us help you achieve success in electronics manufacturing.