In the world of electronics manufacturing, IPC Class 3 represents the pinnacle of quality and reliability, suitable for aerospace, medical devices, and military applications. As a professional contract manufacturer, we adhere strictly to IPC Class 3 standards throughout our PCB Assembly process. From design and material selection to manufacturing and final testing, every step is meticulously controlled to ensure the highest quality and reliability. Here’s a detailed case study on achieving these standards in practice.

1. Material Selection and Handling

Case Study: Choosing High-Quality Solder Paste

Material selection is crucial in achieving IPC Class 3 standards. For instance, when selecting solder paste, we use high-quality, IPC Class 3-compliant solder paste that ensures excellent wettability and appropriate melting points. These solder pastes form robust solder joints under high temperatures, ensuring reliable electrical connections.

- Quality Control on Entry: All materials, including solder paste, are subject to rigorous quality control upon arrival. This includes checking the batch consistency, storage conditions, and expiry dates to ensure optimal performance.

- Storage Conditions: Maintaining controlled environments for storage to prevent contamination and degradation. Solder paste is stored in temperature-controlled conditions to maintain its properties.

2. Equipment Calibration and Parameter Setting

Case Study: Precision Tuning of the Pick-and-Place Machine

The pick-and-place process is a critical step where components are precisely placed on the PCB. Here’s how we ensure accuracy:

- Camera Calibration: Ensuring the cameras are accurately calibrated to recognize and align with the fiducial marks on the PCB, providing precise component placement.

- Nozzle Pressure Adjustment: Adjusting the pressure of the nozzles based on the type and size of components to ensure they are securely picked up and placed without damage.

- Placement Speed Optimization: Balancing speed and accuracy to prevent component misalignment or displacement.

Example Parameters:

- Component Recognition Tolerance: ±0.05 mm to ensure precision placement.

- Nozzle Pressure: Adjusted to 20-30 psi depending on component size.

- Placement Speed: Typically set to 0.5 seconds per component to balance speed and accuracy.

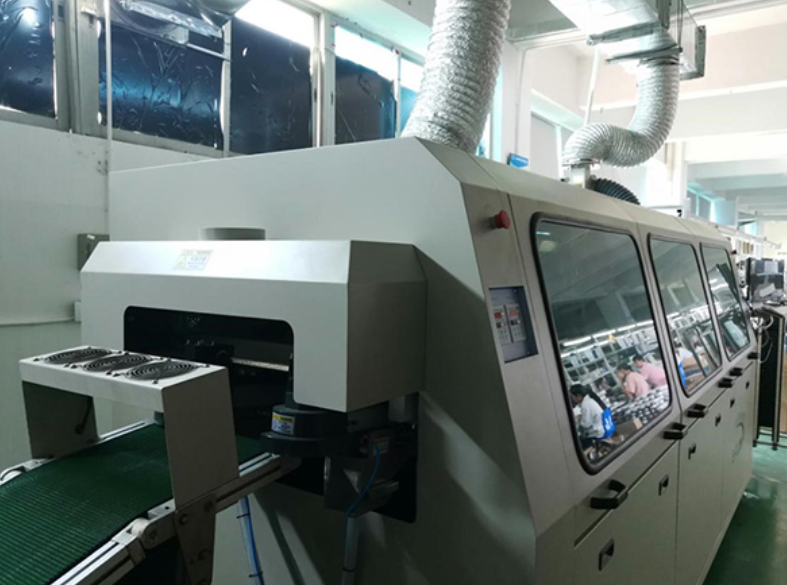

3. Soldering Process Optimization

Case Study: Wave Soldering for Through-Hole Components

For through-hole components, we utilize wave soldering, adjusting key parameters to ensure solder quality:

- Solder Paste Fill Rate: Ensuring the fill rate in through-holes is at least 75% by adjusting soldering parameters.

- Soldering Pressure: Adjusting the pressure to ensure thorough filling of the holes while preventing component damage.

- Preheat and Heat Time: Controlling preheat and heating times to allow even solder flow and robust joint formation.

- Wave Height: Adjusting wave height to ensure complete coverage of component leads and pads, enhancing reliability.

Example Parameters:

- Preheat Temperature: Set to 100-120°C for optimal solder flow.

- Soldering Pressure: Set to 2-3 bar.

- Wave Height: Adjusted to 0.5-1 mm above the PCB surface.

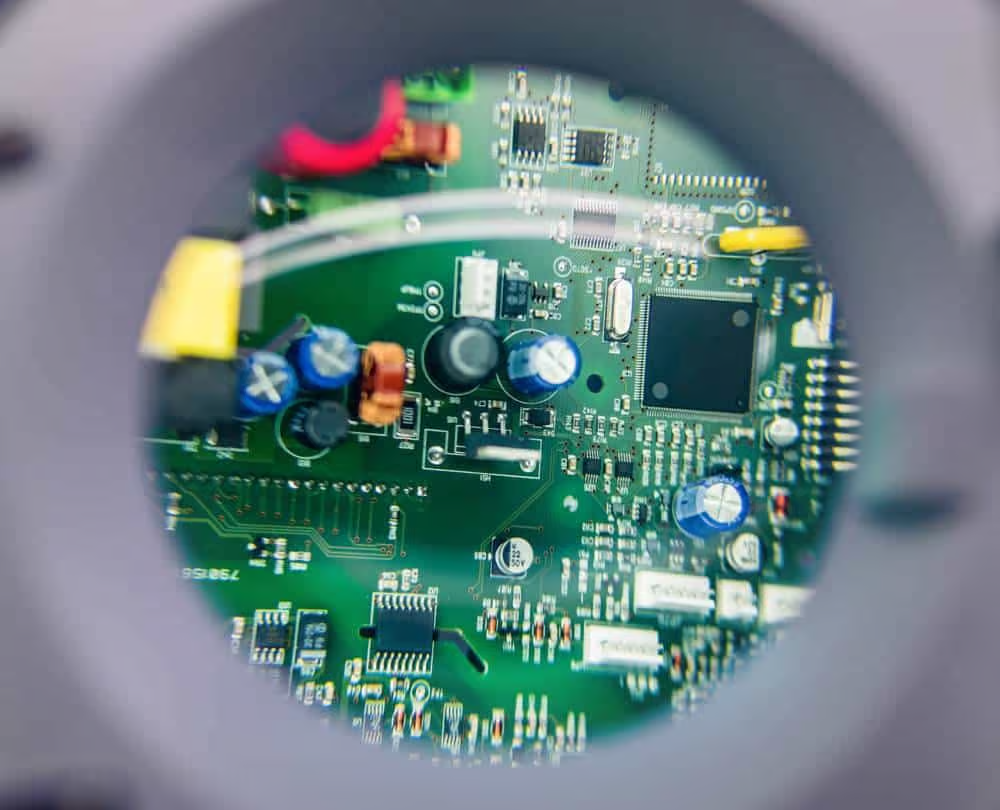

4. Inspection and Quality Control

Case Study: Automated Optical Inspection (AOI)

Post-placement and soldering, we employ AOI to inspect every PCB:

- Solder Joint Inspection: AOI systems check each solder joint’s position and shape to ensure they meet IPC Class 3 standards.

- Defect Identification: Identifying and marking any defects such as voids, bridges, and misalignments for immediate correction.

- Statistical Process Control (SPC): Implementing SPC to monitor production trends and preemptively address potential issues.

Example Parameters:

- Inspection Resolution: 10-15 µm to detect fine defects.

- Defect Threshold: Setting thresholds for acceptable defect rates (e.g., <0.1% for critical components).

5. Continuous Improvement and Customer Feedback

Case Study: Quality Management System (QMS) Implementation

Our commitment to quality extends beyond production through a robust QMS compliant with ISO 9001:

- Production Record Keeping: Detailed recording of every batch’s production and inspection data to ensure traceability and accountability.

- Feedback Analysis: Regularly analyzing customer feedback to identify and rectify issues, continuously improving our processes.

- Corrective Actions: Implementing corrective and preventive actions (CAPA) based on feedback and inspection data to enhance quality and reliability.

Example Initiatives:

- Customer Satisfaction Surveys: Conducted quarterly to gather insights.

- Internal Audits: Bi-annual audits to ensure compliance with IPC Class 3 and ISO standards.

- Training Programs: Continuous training for staff on the latest IPC standards and quality control techniques.

Conclusion

By meticulously controlling material selection, equipment calibration, soldering processes, and implementing rigorous inspection and quality management systems, we consistently meet and exceed IPC Class 3 standards. This comprehensive approach ensures our products are of the highest quality and reliability, fostering trust and satisfaction among our customers. As your contract manufacturer, we are committed to delivering superior electronic manufacturing solutions tailored to your needs.

We hope this detailed case study provides a clear understanding of our stringent processes and dedication to quality. If you have any specific questions or require further information, please do not hesitate to contact us!