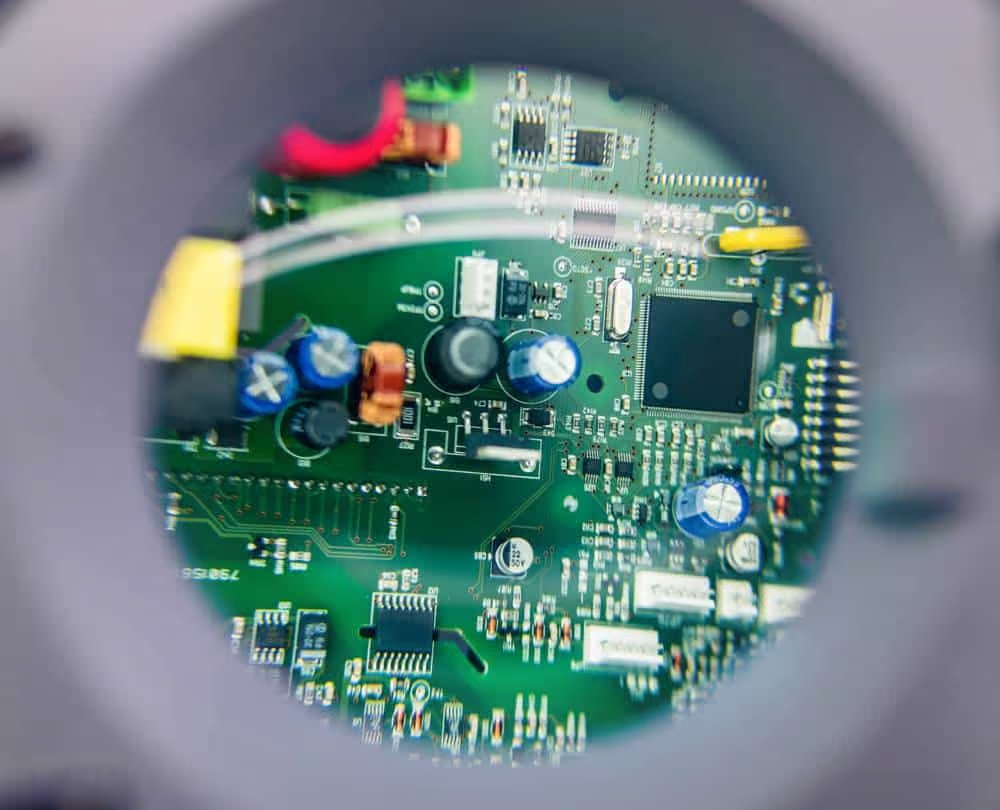

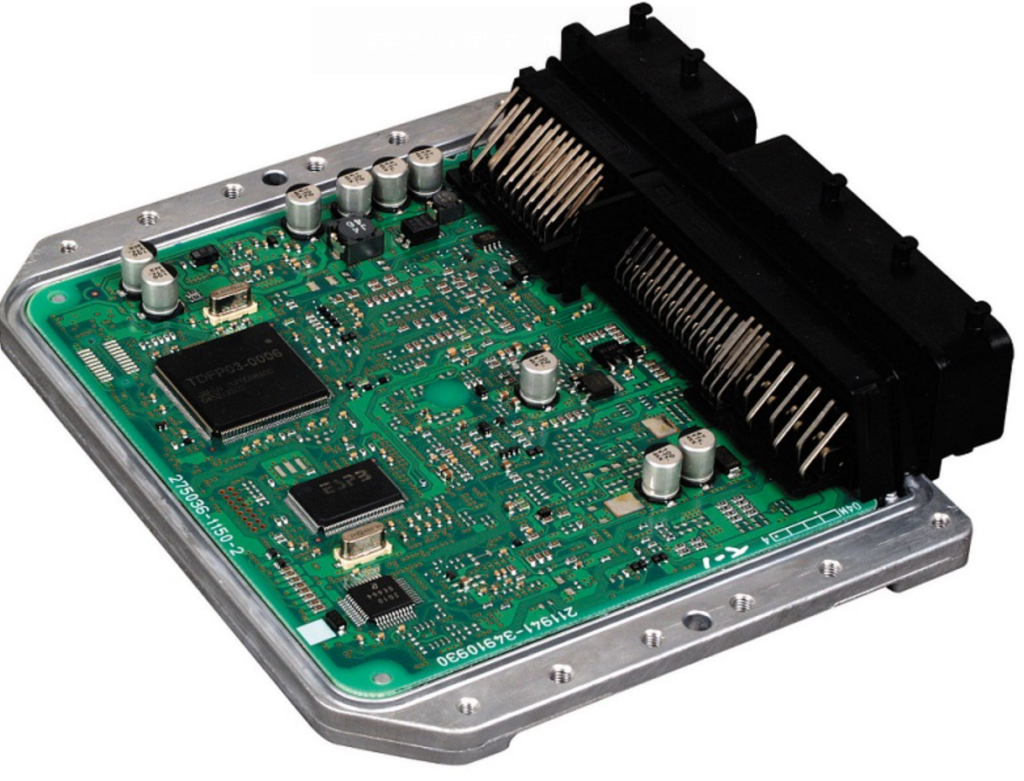

In today’s competitive electronics manufacturing landscape, managing costs and enhancing efficiency are pivotal for success. For manufacturers like XYZ Electronics, optimizing the procurement and production processes for printed circuit boards (PCBs) can lead to significant cost reductions and improved operational efficiency. At Fumax Tech, a leading provider of electronic manufacturing services, we offer comprehensive solutions to help clients achieve these goals. Here’s how we can help:

1. Cost Optimization Analysis

Case Study: Reducing PCB Costs for XYZ Electronics

XYZ Electronics faced escalating costs for their PCB components, impacting their overall production budget. We conducted a thorough analysis of their existing Bill of Materials (BOM) and identified several high-cost components that could be replaced with cost-effective alternatives.

Data Insights:

- Original Cost: $15 per unit for certain PCB components.

- Proposed Alternative: Domestic substitutes at $10 per unit.

By recommending domestic substitutes, we helped XYZ Electronics reduce their component costs by approximately 33%. Additionally, this switch shortened the lead time from 6 weeks to 2 weeks, significantly improving production turnaround.

Outcome:

- Cost Reduction: $300,000 annual savings.

- Lead Time Improvement: 4 weeks reduction in delivery schedule.

2. Production Optimization Analysis

Case Study: Streamlining Production for Improved Efficiency

XYZ Electronics also faced challenges with production efficiency due to complex PCB designs. We proposed design modifications that simplified the mechanical structure and electronic layout, reducing manufacturing complexity.

Data Insights:

- Original Design: Required 10 steps for assembly, leading to higher labor costs.

- Optimized Design: Reduced to 6 steps with fewer components.

These changes led to a 20% reduction in labor time and a 15% decrease in material waste. The optimized design also improved the product’s reliability and reduced the number of defects.

Outcome:

- Labor Time Reduction: 20% decrease.

- Material Waste Reduction: 15% decrease.

- Defect Rate Improvement: 10% decrease.

3. Inventory Management

Case Study: Managing Component Inventory for Stability

For components with volatile prices, XYZ Electronics struggled with price fluctuations impacting their budget. We implemented an inventory management strategy to mitigate these risks.

Data Insights:

- Annual Demand: 6,000 units.

- Bulk Purchase: 6,000 units at a locked-in price.

By purchasing 6,000 units upfront, XYZ Electronics locked in prices and avoided a 25% price increase that occurred later in the year. We aligned purchases with actual demand for stable components to optimize inventory levels.

Outcome:

- Price Stability: Avoided $100,000 in additional costs due to price fluctuations.

- Inventory Efficiency: Reduced excess inventory by 30%.

4. One-Stop Service

Case Study: Integrating Custom Parts for Enhanced Quality

XYZ Electronics required custom parts, including stamping and injection molding, for their new product line. Fumax Tech provided a one-stop solution for both electronic components and custom parts.

Data Insights:

- Integrated Service: Reduced quality control issues by consolidating suppliers.

- Quality Improvement: Enhanced product yield by 25% through streamlined processes.

By handling all material procurement and quality control through a single supplier, we reduced quality risks and improved the overall product quality. The integration also simplified the supply chain, leading to better coordination and fewer delays.

Outcome:

- Quality Improvement: 25% increase in product yield.

- Supply Chain Efficiency: 20% reduction in lead time.

Conclusion

Through these comprehensive optimization strategies, Fumax Tech has helped clients like XYZ Electronics achieve substantial cost savings and efficiency improvements. Our approach to cost optimization, production enhancements, inventory management, and one-stop services ensures that our clients stay ahead in the competitive electronics market.

Partnering with Fumax Tech means benefiting from our expertise in electronic manufacturing services, printed circuit board manufacturers, and printed circuit board assembly. If you’re interested in learning more about how we can help optimize your PCB procurement and production processes, please contact us. We look forward to working with you to drive greater success in your business.