1. Introduction to Tantalum Capacitors

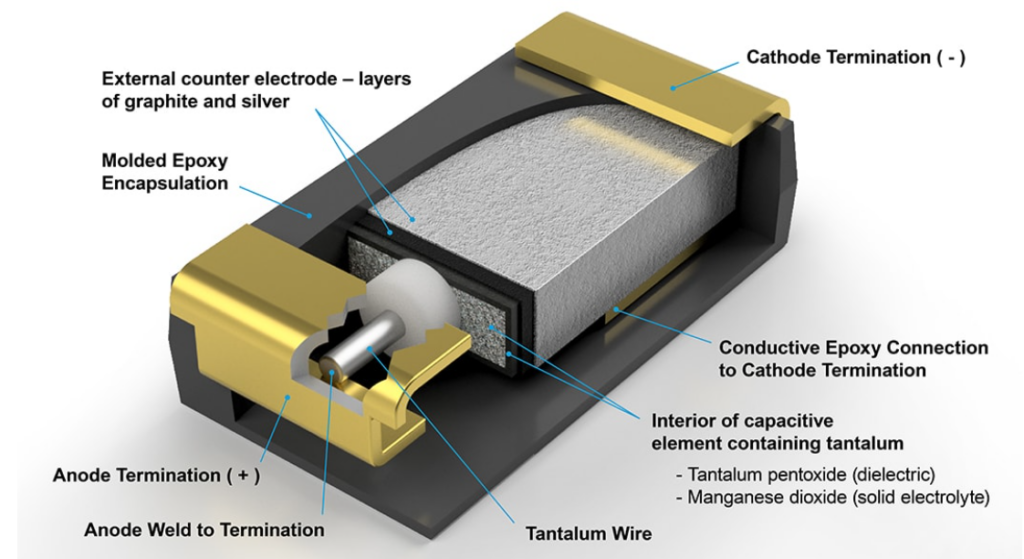

Tantalum capacitors are electrolytic capacitors that use tantalum metal as the anode. Known for their high capacitance, low leakage current, excellent temperature stability, and compact size, these capacitors are highly valued in applications with critical reliability and performance. Compared to aluminum capacitors, tantalum capacitors offer better stability, particularly in extreme environments, making them ideal for use in smartphones, laptops, medical devices, and aerospace technology.

The functionality of a tantalum capacitor relies on the tantalum oxide layer that acts as the dielectric, creating a highly stable electric field. This stability ensures consistent performance over time, especially in high-frequency applications where precision is paramount.

2. Key Applications of Tantalum Capacitors

Due to their small size and stable performance, tantalum capacitors are widely used in the following sectors:

- Mobile Devices: In smartphones and tablets, tantalum capacitors are crucial for power management, filtering, and storage functions, ensuring long-lasting performance and compact design.

- Medical Equipment: The high reliability of tantalum capacitors makes them essential in critical medical devices like pacemakers and MRI machines, where failure is not an option.

- Automotive Electronics: Tantalum capacitors support stable power supply and data processing in modern vehicles’ electronic control units (ECUs), sensors, and entertainment systems.

- Aerospace: With the ability to function reliably in extreme conditions, tantalum capacitors are indispensable in aerospace applications, ensuring the safety and reliability of aircraft systems.

3. How to Choose the Right Tantalum Capacitor

When selecting a tantalum capacitor, consider the following key factors:

- Capacitance Value: Choose a capacitance value that meets the charge storage requirements of your specific application.

- Voltage Rating: Ensure the capacitor’s voltage rating exceeds the circuit’s maximum voltage to prevent failure.

- Temperature Stability: Select a capacitor that can operate within the temperature range of your device’s environment.

- Size and Package Type: Choose the right size and package type based on the space constraints of your PCB design.

4. Top 10 Tantalum Capacitor Manufacturers in China

Here are the top 10 Chinese manufacturers of tantalum capacitors, recognized for their innovation and market presence:

- Kemet Electronics

Kemet is a leading manufacturer with robust R&D capabilities and comprehensive production lines. Their products are widely used in communication, automotive, and industrial applications. - Sunlord Electronics

Specializing in electronic components, Sunlord’s tantalum capacitors have a strong reputation globally, particularly in mobile device and automotive sectors. - Torch Electronics

Known for high-end tantalum capacitors, Torch Electronics focuses on the aerospace and defense industries, ensuring stability in extreme environments. - Vishay Intertechnology

Vishay offers high-quality tantalum capacitors recognized across various industries, including medical devices and consumer electronics. - Fenghua Advanced Technology

As one of China’s largest electronic component manufacturers, Fenghua’s tantalum capacitors are renowned for their superior performance in automotive and power equipment. - Sanhuan Group

Sanhuan Group specializes in new material technology, with tantalum capacitors performing exceptionally in communication equipment and industrial control systems. - Guoguang Electric

Guoguang’s capacitors are known for their high reliability and long lifespan, primarily serving the military and aerospace sectors. - China Aviation Optoelectronics

A key supplier to the aerospace industry, China Aviation Optoelectronics produces tantalum capacitors that are critical for high-reliability applications. - Huaxin Technology

Huaxin is committed to developing high-performance tantalum capacitors, with widespread applications in industrial automation and medical electronics. - Yageo Corporation

Yageo is known for its innovative designs and cost-effective solutions, with tantalum capacitors commonly used in consumer electronics and telecommunications.

5. The Importance of Tantalum Capacitors in PCB Assembly

Tantalum capacitors play a critical role in PCB assembly, managing power, filtering noise, and ensuring the stability of devices under various operating conditions. The use of high-quality tantalum capacitors can significantly enhance the overall performance and reliability of a PCB.

As a professional PCB assembly service provider, we understand the importance of component quality to the final product’s performance. That’s why we strictly adhere to our customers’ BOM (Bill of Materials) while ensuring that all components undergo rigorous validation and quality checks. This meticulous approach guarantees that every PCB we assemble meets the highest standards of reliability and durability.

6. Conclusion and Call to Action

Tantalum capacitors are vital to modern electronics, from reliable medical devices to aerospace systems operating in extreme environments. China’s tantalum capacitor manufacturers play a crucial role in the global market, offering a wide range of products that can enhance your product’s performance and reliability.

If you’re looking for high-quality tantalum capacitors and professional PCB assembly services, we’re here to help. Contact us today to learn more about how we can support your projects with our expertise and top-tier components!