All boards will be 100% functionally tested at Fumax factory. The tests will strictly performed according to customer testing procedure.

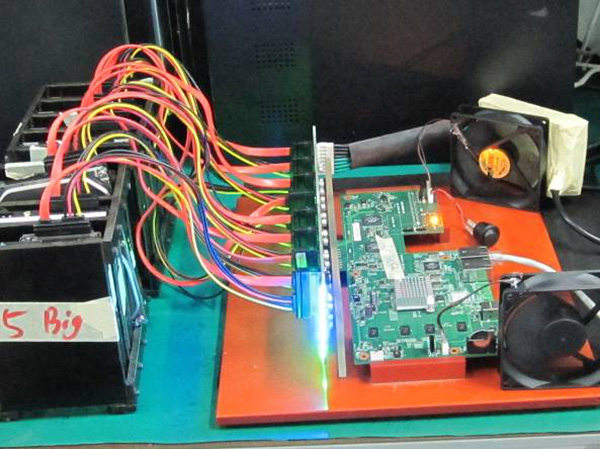

Fumax production engineering will build test fixture for each product. The test fixture will be used to test the products effectively and efficiencies.

A testing report will be generated after each testing, and shared to the customer through email or cloud. Customer can review and track all the testing records with Fumax QC results.

FCT, also known as Functional testing, generally refers to the test after PCBA is powered on. Automation FCT equipment is mostly based on open hardware and software architecture design, which can flexibly expand hardware and quickly and easily establish test procedures. Generally, it can support multiple instruments and can be flexibly configured on demand. It must also have a rich basic Test projects to provide users with a universal, flexible and standardized solution to the greatest extent possible.

Voltage, current, power, power factor, frequency, duty cycle, rotation speed, LED brightness, color, position measurement, character recognition, pattern recognition, voice recognition, temperature measurement and control, pressure measurement control, precision motion control, FLASH, EEPROM online programming, etc.

2. The Difference between ICT & FCT:

(1) ICT is mainly a static test, to check component failure and welding failure. It is carried out in the next process of board welding. The problematic board (such as the problem of reverse welding and short circuit of the device) is directly repaired on the welding line.

(2) FCT test, after power is supplied. For single components, circuit boards, systems, and simulations under normal use conditions, check the functional role, such as the circuit board’s working voltage, working current, standby power, whether the memory chip can read and write normally after power on , The speed after the motor is powered on, the channel terminal on-resistance after the relay is powered on, etc.

To sum up, ICT mainly detects whether the circuit board components are inserted correctly or not, and FCT mainly detects whether the circuit board functions normally.