LCD assembly is the process of assembling the backlight module of the LCD screen and the LCD panel, including assembling the upper polarizer, color filter, TFT LCD panel, TFT substrate, lower polarizer, backlight, wiring, IC and other raw materials in Together, they form a complete LCD screen. PCB assembly is to solder electronic components to PCB to form a complete circuit board and electronic device.

What is PCBA?

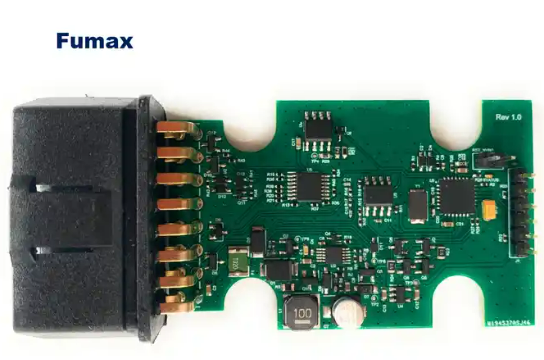

PCBA is the abbreviation of English Printed Circuit Board Assembly. It refers to the process of installing electronic components (such as integrated circuits, resistors, capacitors, etc.) onto a printed circuit board (PCB) through welding. PCBA is to weld electronic components to PCB to form a complete circuit board and electronic device.

What is LCD assembly?

LCD assembly refers to the process of assembling the backlight module of the LCD screen and the LCD panel. This process includes assembling upper polarizer, color filter, TFT liquid crystal panel, TFT substrate, lower polarizer, backlight, wiring, IC and other raw materials to form a complete LCD screen. LCD assembly is one of the important links in manufacturing LCD products, and its quality directly affects the performance and appearance of the product.

What is the difference between LCD assembly and PCB assembly?

LCD assembly and PCB assembly are different electronic manufacturing processes. Their main difference lies in the assembly objects and process flow.

LCD assembly mainly involves assembling the backlight module of the LCD screen and the LCD panel to form a complete LCD screen. This process includes assembling the upper polarizer, color filter, TFT liquid crystal panel, TFT substrate, lower polarizer, backlight, wiring, IC and other raw materials together. LCD assembly is one of the important links in manufacturing LCD products, and its quality directly affects the performance and appearance of the product.

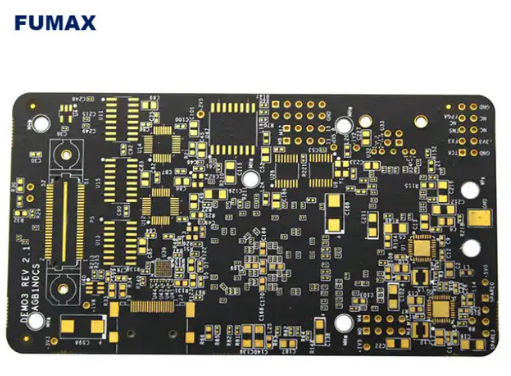

PCB assembly refers to the process of installing electronic components (such as integrated circuits, resistors, capacitors, etc.) onto a printed circuit board (PCB) through welding. PCBA is to weld electronic components to PCB to form a complete circuit board and electronic device. PCB assembly is an important part of electronic products and is used to realize circuit functions. For example, electronic equipment, mobile phones, computers, etc. all require PCBA to control and operate.

In general, the difference between LCD assembly and PCB assembly is mainly reflected in the assembly objects and process flow. LCD assembly mainly involves assembling various components of the LCD screen, while PCB assembly involves welding electronic components to the PCB to form a circuit board and electronic device.

What is the difference between PCBA and LCD assembly?

There are obvious differences in the assembly process and function between PCBA and LCD assembly.

LCD assembly vs PCB assembly

PCBA (Printed Circuit Board Assembly) refers to welding various electronic components (such as chips, resistors, capacitors, etc.) to a printed circuit board (PCB), and completing the final circuit board assembly through steps such as welding, testing and debugging. . PCBA includes circuit board manufacturing, component procurement, and assembly process design. PCBA is an important part of electronic products and is used to realize circuit functions. For example, electronic equipment, mobile phones, computers, etc. all require PCBA to control and operate.

LCD (Liquid Crystal Display) is a flat display technology used to display images and text. It usually consists of a liquid crystal box, a drive circuit and a light source. LCD is a display device, which is different from PCBA. LCD is a display technology used to display images and text. For example, TVs, monitors, smartphones, etc. all use LCD to display images.

In general, the difference between PCBA and LCD assembly is mainly reflected in functions and applications: PCBA is an assembly process to realize circuit functions, while LCD is a display technology.

How much does LCD PCB assembly cost?

The cost of LCD PCB assembly varies depending on assembly process, materials, design and other factors, so a specific cost cannot be given. Generally speaking, the cost of LCD PCB assembly includes material cost, labor cost, equipment cost, management cost, etc. Among them, material costs include the cost of raw materials such as PCB boards, electronic components, and backlight modules; labor costs include wages, training, management and other expenses for assembly personnel; equipment costs include assembly equipment, testing equipment, etc.; management costs include research and development, Purchasing, inventory, quality control and other expenses.

Specific costs need to be evaluated based on specific assembly processes, materials, design and other factors. Generally speaking, the cost of LCD PCB assembly is relatively high because it requires the use of high-precision assembly equipment and raw materials, as well as strict quality control and testing. However, with the continuous advancement of technology and reduction of costs, the cost of LCD PCB assembly is gradually decreasing.

Does the PCB assembly factory provide LCD assembly services?

Generally speaking, PCB assembly factories can provide LCD assembly services. Because LCD assembly and PCB assembly are different electronic manufacturing processes, there is a certain relationship between them. LCD assembly requires assembling the backlight module of the LCD screen and the LCD panel, while PCB assembly involves welding electronic components to the PCB to form a complete circuit board and electronic device. Therefore, PCB assembly factories usually also provide LCD assembly services to meet customer needs.

It should be noted that the LCD assembly services provided by different PCB assembly factories may be different. The specific service content and quality need to be evaluated and selected by customers based on their needs. At the same time, both LCD assembly and PCB assembly have certain technical thresholds and quality control requirements, so it is necessary to choose a factory with experience and technology to cooperate.

If you have PCB assembly or LCD assembly services, please contact us.

LCD PCB assembly service manufacturers in China

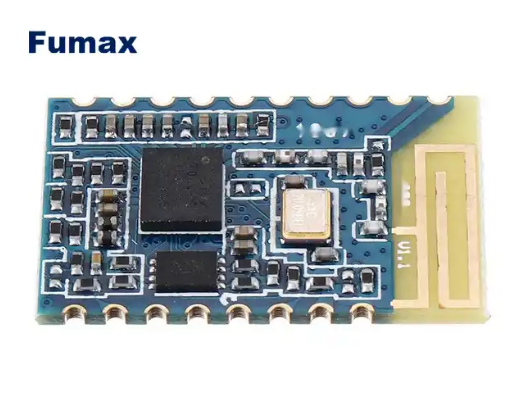

Fumax is an LCD PCB assembly manufacturer in Shenzhen, China, with rich electronic manufacturing experience and a complete quality control system. We focus on providing customers with high-quality and efficient LCD PCB assembly services.

As a professional LCD PCB assembly manufacturer, we have a highly skilled and experienced production team with advanced production equipment and a complete management system. We strictly control every production link to ensure the high quality and reliability of our products.

Our LCD PCB assembly services cover the entire process from design, procurement, assembly to testing and shipment. We provide customized services based on customer needs, including support in material selection, process design, production cycle, etc. At the same time, we also provide after-sales service and technical support to ensure that customers have no worries.

Our advantages are:

- Have advanced production equipment and technology to ensure product quality and efficiency;

- Strict quality control system to ensure product consistency and reliability;

- Professional production team and technical support team to provide a full range of services;

- Flexible service methods and customized services to meet the needs of different customers.

We are committed to providing customers with high-quality LCD PCB assembly services to help customers improve production efficiency, reduce costs, and improve quality. We look forward to cooperating with you to create a better future!