With the advancement of science and technology, LED technology has been widely used in the lighting field. Desk lamps are an important part of home lighting.

Using LEDs as light sources has the advantages of energy saving, environmental protection, and long life.

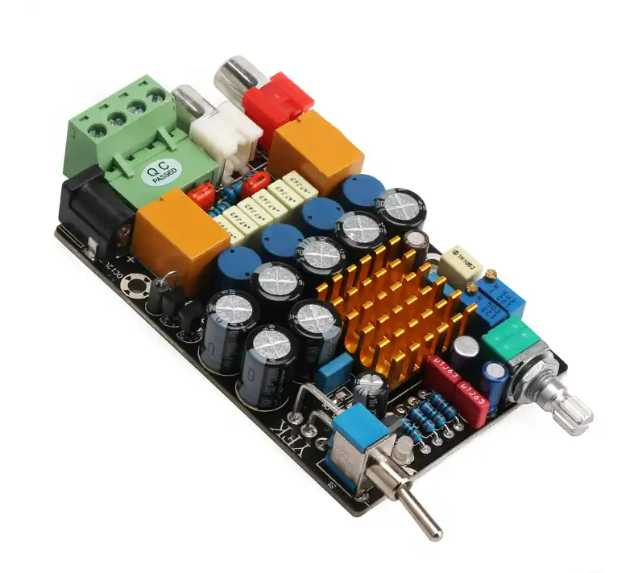

As the core component of LED desk lamps, PCB board assembly technology directly affects the performance and quality of the product. This article will introduce in detail the assembly technology of desk lamp LED PCB board.

LED pcb board introduction

LED pcb board, that is, LED circuit board, is a printed circuit board specially used to install and support LED devices. It has the characteristics of strong conductivity, good insulation, light weight, and high strength, and provides stable physical support and electrical connection for LED devices. The design and assembly of LED PCB boards are of great significance for taking advantage of LEDs and improving the performance of desk lamps.

LED pcb board assembly process

- Device selection and inspection: Select high-quality LED devices and PCB boards to ensure that the specifications and performance of the LED devices match the PCB boards, and inspect the appearance and electrical performance to ensure the quality and reliability of the components.

- PCB board processing: The PCB board is drilled, cut, and polished according to the design requirements to ensure the machining accuracy and surface treatment effect of the PCB board.

- Component welding: Weld the LED components on the PCB board according to the design requirements to ensure stable and reliable welding quality and prevent false soldering, missing soldering and other phenomena.

- Testing and adjustment: After completing the welding, conduct electrical performance testing and adjustment to ensure the normal operation of the LED device.

- Assembly and packaging: Assemble the radiator, driver and other components onto the PCB board, and take necessary reinforcement and protective measures. Finally, packaging is carried out to ensure that the product is not damaged during transportation and storage.

LED pcb board assembly key technologies

- Welding technology: Welding is a key link in the LED pcb board assembly process, which directly affects the quality and performance of the product. Use appropriate welding processes and welding materials to ensure the electrical conductivity and mechanical strength of the welding points and avoid welding defects.

- Layout and wiring technology: Reasonable layout and wiring can improve the electrical performance and heat dissipation performance of the LED PCB board. In terms of layout, the principles of even distribution, simplicity and clarity should be followed to improve wiring efficiency and reduce heat concentration. In terms of wiring, factors such as current size and signal transmission rate need to be considered, and appropriate line widths and line spacing should be selected.

- Thermal design and heat dissipation technology: The luminous efficiency of LEDs is greatly affected by temperature, so good thermal design and heat dissipation technology are crucial. During the assembly process, full consideration should be given to the thermal conductivity of the PCB board and the selection and installation of the heat sink to ensure that the temperature of the LED device is stable during operation.

- Electromagnetic compatibility design: In order to reduce the impact of electromagnetic interference on the LED PCB board, electromagnetic compatibility needs to be fully considered during the design and assembly process. Take effective shielding measures, reasonable layout, and selection of appropriate filters to improve the electromagnetic anti-interference ability of the product.

- Protection and reinforcement technology: During the assembly process of LED PCB boards, necessary protection and reinforcement measures should be taken to improve the durability and stability of the product. For example, the PCB board should be waterproofed and dustproofed, and key parts should be reinforced.

Table lamp LED pcb board assembly manufacturer

Fumax desk lamp LED PCB board assembly is a service-oriented front-end PCBA supplier that integrates solution R&D, design and differentiated customized production.

The company focuses on the development and design of control circuit board software and hardware and PCBA (PCB assembly) production.

Its products include smart home controls, electronic therapy instrument control circuits, power bank circuit boards, etc. It has rich R&D and production experience.

To learn more about electronic design, PCB assembly, and PCB reverse engineering, please contact us.

Assembly summary of desk lamp LED pcb board

The assembly technology of table lamp LED PCB boards is a key factor in ensuring product quality and performance. During the assembly process, process requirements should be strictly observed, reasonable layout and wiring principles should be followed, and attention should be paid to the application of thermal design, electromagnetic compatibility design, and protection and reinforcement measures. By continuously optimizing and improving assembly technology, we improve the performance and quality of desk lamps to meet market demand.