With the advancement of science and technology and the increasing demand of consumers for intelligent life, remote-controlled night lights have gradually become the new favorite in the field of home lighting.

This night light not only has basic lighting functions, but also incorporates remote control technology, providing users with a more convenient and intelligent lighting experience. In order to meet the needs of the market, it is particularly important to design and implement an efficient and stable remote control circuit board night light PCB assembly solution.

Remote control circuit board night light PCB assembly solution design

- Determine functional requirements: Before starting the design, it is necessary to clarify the main functions and performance requirements of the night light. For example, whether it needs to support wireless remote control, whether it needs to have timer switch function, brightness adjustment function, etc.

- Choose the appropriate PCB material: Choose the appropriate PCB material according to the working environment and functional requirements of the night light. Commonly used PCB materials include FR4, CEM-1 and aluminum substrates. These materials have different electrical properties and heat resistance and need to be selected according to actual needs.

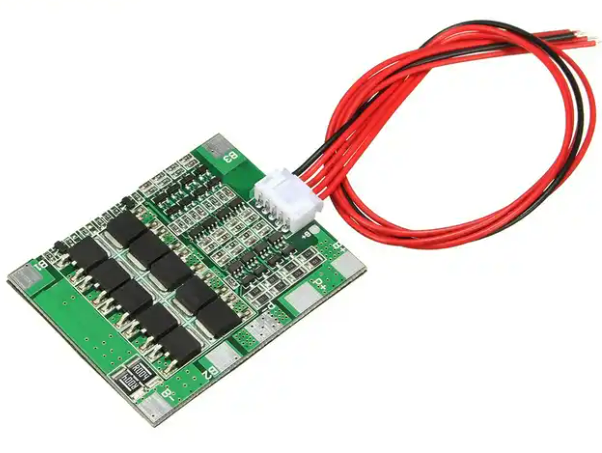

- Design PCB layout: Determine the PCB layout according to the functional modules to ensure that the connection distance between each component is reasonable to improve assembly efficiency and stability. At the same time, the heat dissipation design of the PCB should be taken into consideration to ensure that the night light will not overheat during long-term operation.

- Component selection and layout: According to functional requirements, select appropriate electronic components and layout them. When selecting components, parameters such as temperature resistance, voltage resistance, and electrical performance should be taken into consideration to ensure that the night light can work stably. In addition, the packaging form of the component also needs to be considered to ensure that the component can be installed easily and accurately during the assembly process.

- Consider repairability: When designing the PCB layout, subsequent repair and maintenance work should be taken into consideration. A reasonable layout should facilitate component replacement and fault detection, thereby improving maintenance efficiency and reducing maintenance costs.

- Determine the PCB manufacturing process: Select an appropriate PCB manufacturing process based on the specific requirements of the design and the complexity of the PCB. For simple PCBs, conventional etching processes can be used; for complex PCBs, more advanced processes such as multi-layer stacking or micro-hole technology may be required.

- Issue detailed design drawings: After completing the above steps, detailed design drawings need to be issued, including component layout drawings, wiring diagrams, component lists, etc. These drawings should be marked with various parameters and requirements in detail so that subsequent assembly and production work can proceed smoothly.

Remote control circuit board night light PCB assembly implementation

- PCB manufacturing: According to the requirements of the design drawings, the selected PCB materials are sent to a professional PCB manufacturing factory for processing. During the manufacturing process, it is necessary to ensure that the quality and accuracy of the PCB meet the design requirements.

- Component procurement and testing: Purchase the required electronic components according to the component list. After receiving the components, quality inspection is performed to ensure that the quality and performance of the components meet the design requirements.

- PCB welding: Weld the qualified electronic components to the PCB according to the designed layout. During the welding process, it is necessary to ensure the welding quality and avoid virtual welding, missing welding, etc.

- Assembly and debugging: Fix the welded PCB to the corresponding position of the night light, and assemble it as a whole. After the assembly is completed, conduct preliminary debugging to check whether the basic functions of the night light are normal.

- Aging test: After preliminary debugging, perform an aging test to further check the performance and stability of the night light. During the aging test process, it is necessary to simulate the actual use environment and conduct long-term and high-intensity tests on the night light to fully expose potential problems.

- Quality inspection and improvement: Conduct quality inspection on night lights that have undergone aging testing to check whether there are faults or performance issues. Make improvements to existing problems to improve the overall performance and quality of the night light.

- Packaging and leaving the factory: Finally, the qualified night lights are packaged and prepared for shipment from the factory. Packaging should take into account shock-proof, moisture-proof and other factors during transportation to ensure that the product is not damaged during transportation.

summary

This article provides a solution for remote control circuit board night light PCB assembly. By clarifying functional requirements, selecting appropriate PCB materials and manufacturing processes, and performing component selection and layout, the design work of the night light PCB can be completed; through PCB manufacturing, component procurement and testing, welding, assembly and debugging, aging testing, Steps such as quality inspection and improvement can complete the manufacturing and quality control of night lights; finally, the entire product production process is completed through steps such as packaging and shipment.