With the rapid development of the new energy and electric vehicle markets, the importance of the Battery Management System (BMS) as the core component of the battery pack has become increasingly prominent.

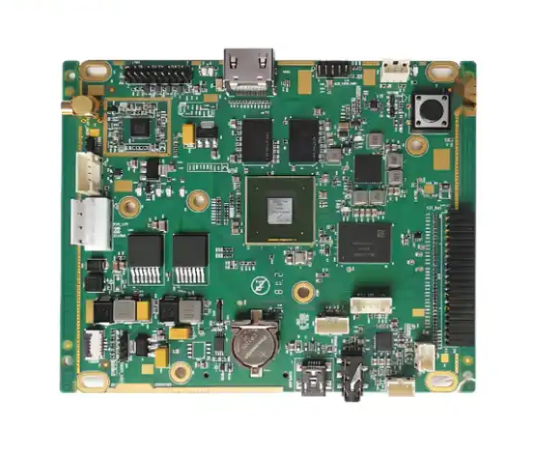

As the core hardware of BMS, the BMS battery management control board is responsible for monitoring, managing and controlling the working status of the battery pack to ensure the safe, stable and efficient operation of the battery pack.

This article will introduce in detail the assembly process of the BMS battery management control board, including material preparation, circuit design, hardware assembly, software testing and quality control, in order to provide useful reference for practitioners in related fields.

Material preparation

- Control board substrate: Materials with high insulation, good thermal conductivity and chemical stability are usually selected, such as FR4, CEM-1, etc.

- Electronic components: including microprocessors, sensors, power electronic devices, communication interfaces, etc. The quality and performance of these components directly affect the stability and reliability of the control board.

- Cables and connectors: used to connect the control board with other battery components or external devices, and must have good conductivity and stability.

- Radiator and heat dissipation materials: used for heat dissipation of the control board to ensure the normal operation of the control board in high temperature environments.

- Other auxiliary materials: such as insulation materials, fixings, labels, etc.

Circuit design

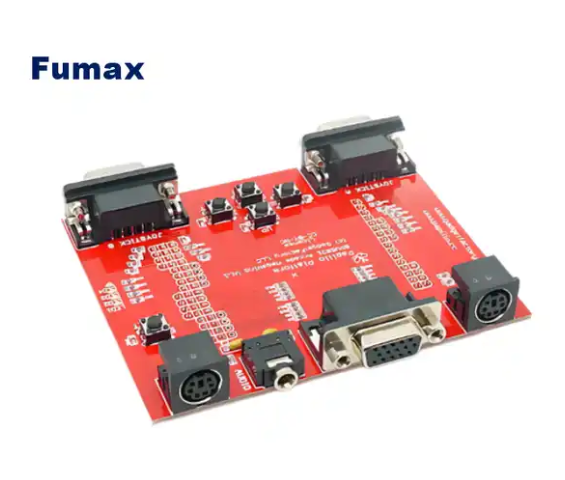

- Schematic design: Based on the functional requirements and performance indicators of the BMS, design the circuit schematic diagram of the control board, including microprocessor selection, power supply circuit, sensor circuit, communication interface circuit, etc.

- PCB wiring design: Convert the schematic diagram into a PCB wiring diagram, reasonably lay out components and wire paths, and ensure the stability and reliability of the circuit. At the same time, issues such as heat dissipation and electromagnetic compatibility also need to be considered.

- PCB production: The PCB wiring diagram is handed over to professional manufacturers for production. Quality and accuracy must be strictly controlled during the production process.

Hardware assembly

- Component welding: Weld electronic components to the PCB. The correct welding sequence and welding parameters must be followed during the welding process to ensure welding quality and reliability.

- Installation of connecting wires and connectors: According to the circuit design, install the connecting wires and connectors to the corresponding positions to ensure a stable and reliable connection.

- Installation of radiators and heat dissipation materials: According to the heat dissipation requirements of the control board, install radiators and heat dissipation materials to ensure the normal operation of the control board in high temperature environments.

- Installation of other auxiliary materials: such as insulation materials, fixings, labels, etc., shall be installed according to the design requirements.

Software test

- System function test: Carry out various functional tests on the control board to ensure that all functions operate normally and meet the design requirements.

- Performance test: Test the performance indicators of the control board, such as sampling accuracy, communication rate, power consumption, etc., to ensure that performance requirements are met.

- Stability test: Stability test of the control board under long-term operation and harsh environment to ensure the stability and reliability of the control board.

- Safety test: Test the safety performance of the control board, such as over-current protection, over-temperature protection, short-circuit protection, etc., to ensure that the control board can respond quickly under abnormal conditions to protect the safety of the battery pack.

QC

- Raw material quality control: Conduct strict quality inspections on purchased raw materials to ensure that the quality and performance of the raw materials meet the requirements.

- Production process quality control: Strict quality control is carried out on each link during the production process to ensure that the quality and accuracy of each link meet the requirements.

- Final product quality inspection: Conduct strict quality inspection on the final product, including appearance inspection, functional testing, performance testing, etc., to ensure that the quality and performance of the final product meet the requirements.

Summarize

This article introduces in detail the assembly process of the BMS battery management control board, including material preparation, circuit design, hardware assembly, software testing and quality control.

As the new energy and electric vehicle markets continue to develop, the demand for BMS battery management control boards will continue to grow, and its technical level and performance requirements will also continue to improve.

In the future, we look forward to promoting the further development and improvement of BMS battery management control board technology through continuous research and innovation, and making greater contributions to the development of new energy and electric vehicles.

At the same time, we also hope that practitioners in related fields can continue to learn and master new technologies and new methods, and jointly promote technological progress and industrial development in the fields of new energy and electric vehicles.