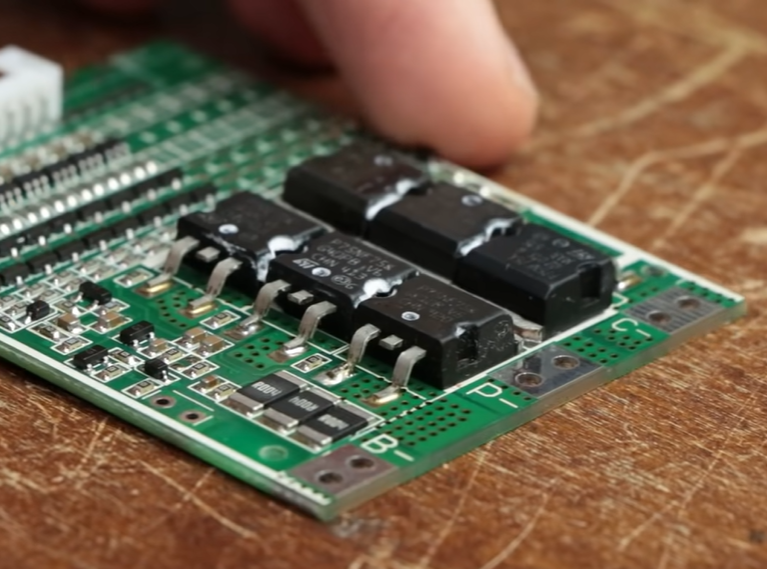

The BMS (battery management system) control board is the core component of the electric vehicle battery pack.

It is mainly used to monitor the operating status of the battery pack, protect the battery pack from overcharge and over-discharge, and realize the energy of the battery pack. Management and other functions.

The following is a detailed introduction to the BMS control board design:

Hardware design

The hardware design of the BMS control board mainly includes the main control module, sampling module, protection module, communication module and human-machine interface. The main control module is the center of the entire control panel, responsible for processing all battery pack information and controlling the work of each module.

The sampling module is responsible for collecting information such as voltage, current, and temperature of the battery pack and single cells, and transmits the data to the main control module. When the protection module detects an abnormality in the battery pack, it can quickly cut off the power supply to protect the battery pack from damage.

The communication module is responsible for data exchange with other devices, including communication with other controllers, charging piles and other devices.

The human-machine interface can display the operating status and alarm information of the battery pack in real time, making it convenient for users to view and maintain.

During the hardware design process, factors such as component selection, circuit board layout and wiring, and component welding methods need to be considered. In addition, electromagnetic compatibility design and reliability design are also required to ensure that the control board can work stably and reliably in complex electromagnetic environments and harsh working conditions.

Software design

The software design of the BMS control board includes the design of the main program and each subprogram. The main program is mainly responsible for initializing each module, reading sampling data, handling abnormal situations, controlling the protection module and communication module, etc. Subprograms include battery pack information collection programs, data processing programs, protection control programs and communication programs, etc. Software design needs to follow principles such as modularity, readability, maintainability, and scalability to improve software quality and reliability.

During the software design process, aspects such as software architecture design, algorithm optimization and implementation, exception handling and fault-tolerance technology need to be considered. In addition, software testing and verification are required to ensure the correctness and stability of the software.

Communication protocol design

The BMS control board needs to exchange data with other devices, so corresponding communication protocols need to be designed. Communication protocol design needs to consider factors such as the choice of communication interface, definition of data format, communication rate and communication security. Communication protocols should be simple and easy to understand, easy to implement and maintain. In addition, compatibility and interoperability with other devices need to be considered to facilitate the interconnection and interoperability of multiple devices.

Human-computer interface design

The human-machine interface is an important part of the BMS control board, which is used to display the operating status and alarm information of the battery pack in real time. Human-computer interface design needs to consider factors such as the layout of the interface, the selection of display content, and the display method. The interface should be concise and easy to understand and operate. The display content should include the voltage, current, temperature and other information of the battery pack, as well as alarm information and operating prompts. The display method can use LED indicators, LCD screens or touch screens.

Safety and reliability design

The BMS control board is the core component of the electric vehicle battery pack, and its safety and reliability are crucial. In the design of BMS control board, a series of safety and reliability measures need to be taken, including component screening and detection, fire and moisture-proof design of circuit boards, software fault tolerance and error correction technology, etc.

In addition, tests and verifications such as environmental adaptability testing, life testing and electromagnetic compatibility testing are also required to ensure the safety and reliability of the control board.

To sum up, the design of BMS control board needs to comprehensively consider factors such as hardware, software, communication protocols, human-machine interface, safety and reliability.

Through reasonable hardware selection and circuit board design, excellent software algorithms and exception handling technology, simple and easy-to-understand communication protocols and human-machine interface design, as well as strict safety and reliability testing and verification, high-performance and high-performance products can be created. The reliable BMS control board provides strong support for the development of electric vehicles.