During the electric vehicle controller PCB assembly process, multiple technical requirements need to be considered to ensure its performance and stability.

Here are some key technical requirements:

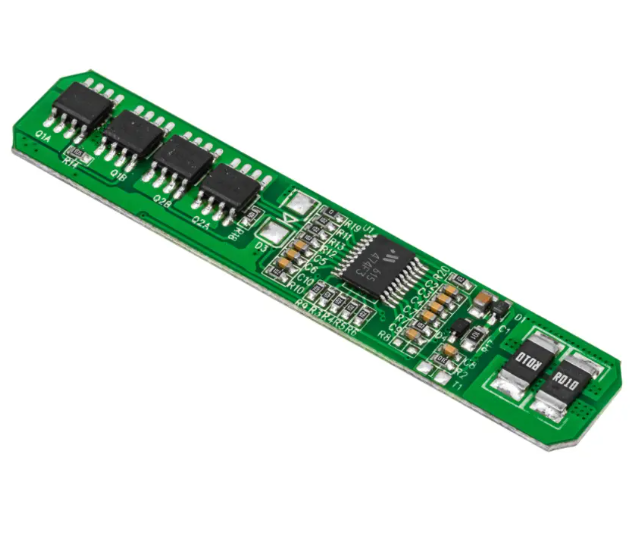

- Component layout: According to the circuit function and performance requirements, the location of components should be reasonably arranged to meet the requirements of wiring, heat dissipation, electromagnetic compatibility, etc. Important components such as main control chips and power circuit modules should be given priority to ensure that they are stable and reliable on the PCB.

- Electromagnetic compatibility: Electric vehicle controllers involve high voltage and high current circuits, which are prone to electromagnetic interference. In order to reduce the impact of electromagnetic interference on controller performance, a series of electromagnetic compatibility measures need to be taken. For example, component layout should minimize line length, use appropriate components such as filter capacitors and ferrite beads, and carry out effective grounding design.

- Heat dissipation design: Electric vehicle controllers generate a large amount of heat during operation, so effective heat dissipation design is required to ensure that components are not damaged due to overheating. Depending on the calorific value of different components and the working environment temperature, natural heat dissipation, forced air cooling or liquid cooling can be used. When designing, full consideration must be given to the selection of heat dissipation paths, radiators, and heat dissipation materials to ensure that heat can be effectively dissipated.

- Wiring technology: Wiring is a key link in PCB assembly and directly affects the performance and stability of the controller. During the wiring process, certain rules and specifications should be followed, such as avoiding bad wiring such as sharp angles, right angles, or circular loops, and maintaining even distribution and appropriate spacing of lines. In addition, for key lines such as clock lines, high-current lines, and sensitive signal lines, additional shielding, filtering, and grounding measures should be taken to reduce signal interference and loss.

- Reliability design: Electric vehicle controllers need to have high reliability and long life, so a series of reliability design measures should be taken during the PCB assembly process. For example, use high-quality electronic components and soldering materials, carry out reasonable PCB design and multi-layer board layout, and use reliable soldering processes such as wave soldering and reflow soldering. In addition, environmental adaptability testing, life testing and reliability evaluation should also be carried out to ensure the reliability and stability of the controller.

- Quality inspection and control: During the PCB assembly process, strict quality inspection and control should be carried out to ensure that every link meets the design requirements and quality standards. For example, quality inspection of components, testing of welding quality, functional and performance testing of finished products, etc. Unqualified components, welding points and finished products should be traced and processed to ensure that every link meets quality requirements.

- Environmental adaptability design: Electric vehicle controllers may work under various environmental conditions, so they need to have good environmental adaptability. When designing, the effects of temperature, humidity, salt spray, vibration and other factors on the controller should be fully considered, and corresponding protective measures should be taken. For example, the PCB should be treated with three-proof coating, and components and connectors with good sealing should be selected.

- Standardization and modular design: In order to improve the efficiency and reliability of PCB assembly, certain standardization and modular design principles should be followed. For example, the packaging of components should be standardized, and the size and interface of PCB should comply with industry standards. Through standardization and modular design, unnecessary differences and complexity can be reduced, and production efficiency and product quality can be improved.

- Maintainability and scalability: In order to facilitate subsequent maintenance and upgrades, the controller PCB design should consider maintainability and scalability. For example, leave appropriate maintenance interfaces and expansion areas on the PCB to facilitate the replacement of components or the addition of new functions. At the same time, connectors and structural parts that are easy to disassemble and assemble should also be used to facilitate maintenance personnel to troubleshoot and replace damaged parts.

- Safety and environmental protection requirements: During the assembly process of the electric vehicle controller PCB, relevant safety and environmental protection regulations and requirements should be followed. Select components and materials that meet safety standards, set up safety protection measures, and avoid the use of harmful substances. In addition, a complete environmental management system should be established to properly handle and recycle waste during the production process to reduce the impact on the environment.

- Testing and verification: During the PCB assembly process, sufficient testing and verification should be carried out to ensure that every link meets the design requirements and quality standards. Test content includes but is not limited to: component testing, welding quality inspection, functional testing, performance testing, environmental adaptability testing, etc. Through testing and verification, potential problems can be discovered and solved in time, improving product reliability and stability.

- Production process automation: In order to improve production efficiency and product quality, the PCB assembly process should be automated as much as possible. Automated production lines can reduce the impact of human factors on product quality, improve production efficiency, and reduce production costs. Automation equipment includes but is not limited to: automatic placement machines, automatic welding machines, automatic detection equipment, etc.

- Supply chain management: Electric vehicle controller PCB assembly involves multiple suppliers and raw materials, so a complete supply chain management system needs to be established. By evaluating and screening suppliers, ensuring the quality and reliability of raw materials, and strengthening communication and collaboration with suppliers, the stability and reliability of the entire supply chain can be ensured.

- Continuous improvement and optimization: With the continuous development of technology and changes in market demand, the technical requirements for electric vehicle controller PCB assembly are also constantly updated and optimized. Therefore, we should continue to pay attention to industry dynamics and technological development trends, and timely adjust and improve production processes and technical requirements to improve product competitiveness.

- Personnel training and quality improvement: The skills and quality of staff have a direct impact on the quality and efficiency of PCB assembly. Skills training and quality improvement should be provided to employees regularly to improve their professional level and operational skills, and enhance their ability to master new technologies and processes. At the same time, quality awareness education should be strengthened to improve employees’ awareness of the importance of product quality and cultivate their rigorous and meticulous work attitude.

To sum up, the technical requirements for electric vehicle controller PCB assembly involve many aspects, and it is necessary to comprehensively consider performance, reliability, environmental adaptability, safety and other aspects.

By following principles such as reasonable layout, electromagnetic compatibility, and heat dissipation design, and taking a series of quality inspection and control, standardization, and modular design measures, we can ensure that the performance and stability of the controller meet the requirements.

At the same time, strengthening management in testing and verification, production process automation, supply chain management, as well as investment in continuous improvement and optimization, personnel training and quality improvement will help improve production efficiency and product quality, and enhance product market competition. force.