What are Motors and Their Types?

Motors are essential devices that convert electrical energy into mechanical energy, powering countless applications from household appliances to industrial machinery. Understanding the different types of motors is crucial for selecting the right one for your needs. Here are the main types of motors:

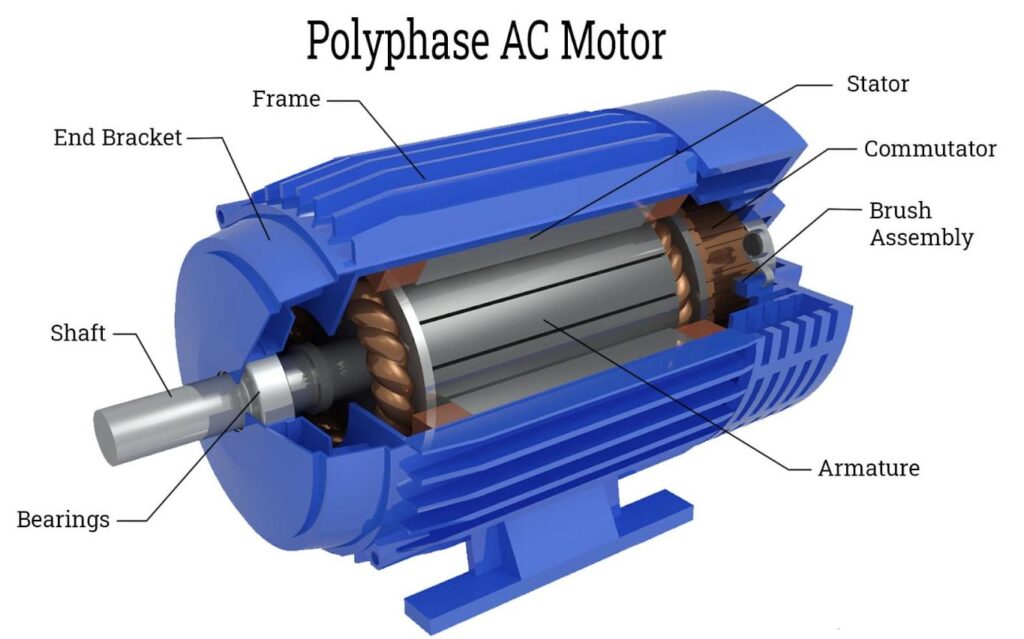

- AC Motors (Alternating Current Motors): Common in household appliances and industrial equipment. They include synchronous and asynchronous (induction) motors.

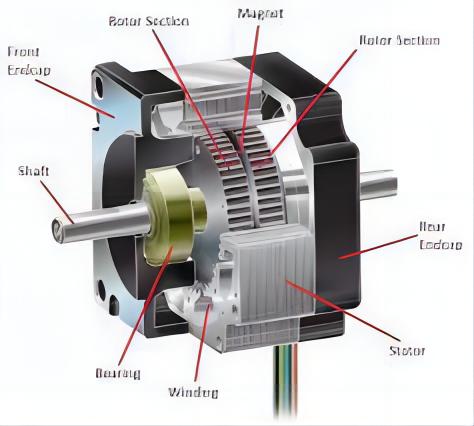

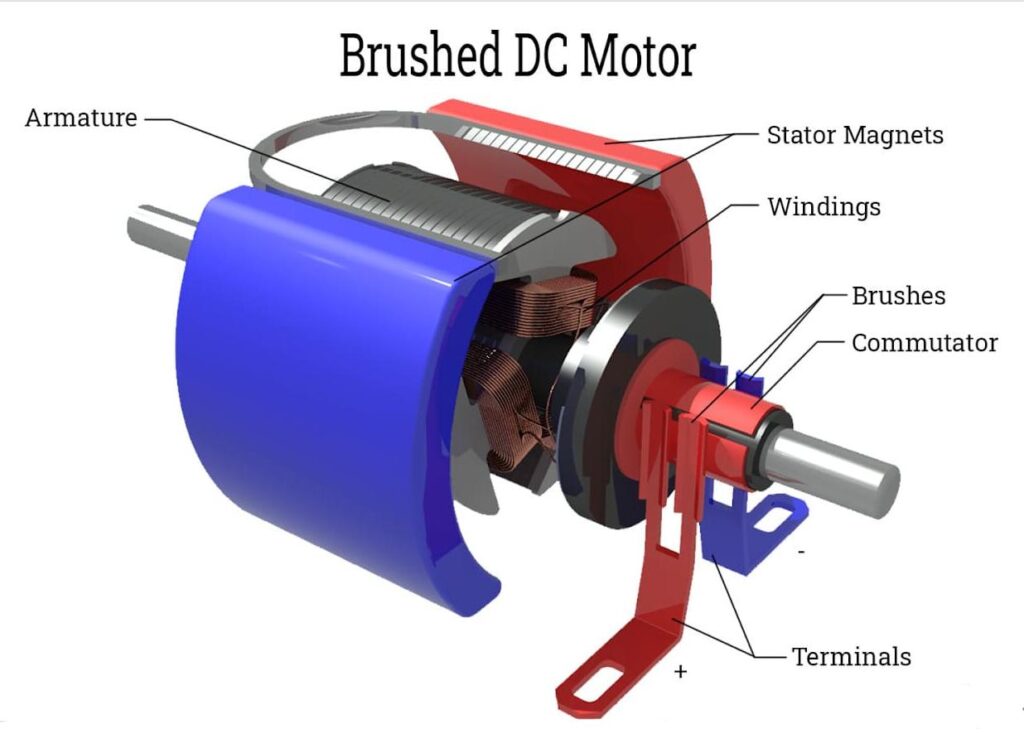

- DC Motors (Direct Current Motors): Found in applications requiring precise speed control, such as electric vehicles and robotics. Types include brushed and brushless DC motors.

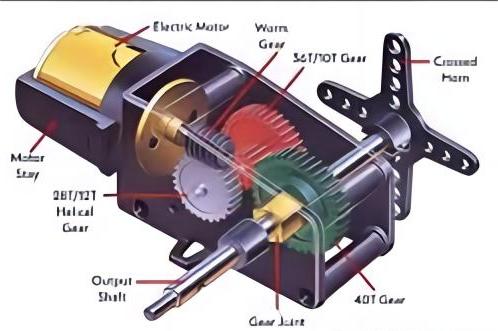

- Stepper Motors: Used for precise control of position and speed, ideal for 3D printers and CNC machines.

- Servo Motors: Provide high efficiency and precise control, commonly used in robotics, conveyor systems, and CNC machinery.

Designing and Producing Motor Control PCBs

Designing and producing control PCBs (Printed Circuit Boards) for motors involves specific requirements and attention to detail to ensure optimal performance and reliability. Here are some key points for each motor type:

- AC Motor Control PCB:

- Component Selection: Use robust components to handle high currents and voltages.

- Thermal Management: Ensure adequate heat dissipation through heat sinks or thermal vias.

- Noise Reduction: Implement filtering techniques to minimize electromagnetic interference (EMI).

- DC Motor Control PCB:

- Current Regulation: Include components for current sensing and regulation to protect the motor.

- Power Supply: Ensure a stable and noise-free power supply for consistent performance.

- Compact Design: Optimize the layout for space efficiency, especially for applications like drones and small robots.

- Stepper Motor Control PCB:

- Microstepping Control: Implement microstepping for smoother and more precise motor movements.

- Heat Dissipation: Ensure effective thermal management due to continuous high current operation.

- Signal Integrity: Maintain signal integrity for accurate step generation and motor control.

- Servo Motor Control PCB:

- Feedback Integration: Incorporate feedback mechanisms like encoders for precise control.

- Power Management: Use efficient power management to handle peak currents during rapid movements.

- Noise Filtering: Implement filters to reduce noise from the motor and the environment.

Top 10 Chinese Motor Manufacturers

China is home to some of the world’s leading motor manufacturers. Here’s a rundown of the top 10 companies:

- Shenyang Machine Tool Co., Ltd. (SMTCL):

- Specializes in high-precision, high-performance motors used in various industries including automotive and aerospace.

- Harbin Electric Corporation (HE):

- Known for manufacturing large-scale motors for power generation, including hydro, thermal, and nuclear power applications.

- CRRC Times Electric Co., Ltd.:

- Focuses on motors for rail transit systems, including high-speed trains and metros.

- Shanghai Electric Group Co., Ltd.:

- Produces motors for wind power, marine propulsion, and industrial applications.

- Jiangsu Anchi Electric Co., Ltd.:

- Renowned for its small and medium-sized motors used in home appliances, power tools, and industrial equipment.

- Dongfang Electric Corporation (DEC):

- Manufactures motors for power generation equipment, including turbines and generators.

- Guangzhou Electric Co., Ltd.:

- Offers a wide range of industrial motors, focusing on energy-efficient and high-performance models.

- Rexnord Shaanxi Power Machinery Co., Ltd.:

- Produces motors for heavy-duty applications such as mining, construction, and port machinery.

- Wuxi Weifu Electric Co., Ltd.:

- Specializes in automotive motors, particularly for electric and hybrid vehicles.

- Ningbo Fangtai Electric Co., Ltd.:

- Known for its small motors used in household appliances, medical devices, and office equipment.

These companies are at the forefront of motor manufacturing, known for their innovation, quality, and contribution to various industries. Whether you need a motor for industrial machinery, home appliances, or cutting-edge robotics, these top Chinese manufacturers offer reliable and high-performance solutions.

Conclusion

Understanding the different types of motors and the specific requirements for designing motor control PCBs is crucial for ensuring optimal performance. With a solid grasp of these concepts, you can better appreciate the capabilities and contributions of China’s top motor manufacturers. These companies continue to lead the way in innovation and quality, powering the future of countless applications worldwide.