Light strip board LED single-sided aluminum substrate prototype factory – a secret base for professional manufacturing.

In the lighting industry, especially in the field of LED lighting, there is a name that everyone knows, and that is the light strip board LED single-sided aluminum substrate prototyping factory.

This is a professional manufacturer integrating R&D, production, sales and service. It has won praises from many customers around the world for its excellent product quality and innovative technology.

- Strong R&D capabilities

- Advanced production equipment

- Strict quality control

- Professional service team

- Continuous innovation and research and development

- Global perspective

- Strong supply chain management

- Pay attention to environmental protection and social responsibility

- Excellent corporate culture and team building

- Excellent customer reputation and industry recognition

- PCB light bar panel led single-sided aluminum substrate manufacturing company

Strong R&D capabilities

The light strip board LED single-sided aluminum substrate prototyping factory has a professional R&D team as its core and continuously invests manpower and material resources in technology research and development and product innovation. They focus on cutting-edge technologies in the lighting industry and actively explore new application areas to meet the changing needs of the market.

Advanced production equipment

The company has advanced production equipment, including precision machining centers, fully automated production lines, etc. These equipments ensure that every product reaches the highest quality standards, allowing the company to maintain its leading position in the fierce market competition.

Strict quality control

In the light strip LED single-sided aluminum substrate proofing factory, the concept that quality is life is deeply rooted in the hearts of the people. The company has a complete quality control system, and every link is strictly controlled from the procurement of raw materials to the delivery of finished products. They know that only high-quality products can win customers’ trust and market recognition.

Professional service team

The company has a professional service team who are committed to providing customers with a full range of services. Whether it is pre-sales consultation or after-sales service, they will meet customer needs with a professional attitude and efficient working style.

Continuous innovation and research and development

In the ever-changing market environment, the light strip LED single-sided aluminum substrate prototype factory always adheres to innovation and research and development. They constantly introduce new products and technologies to meet market demands and customer development needs. The company has obtained a number of patented technologies and maintains a leading position in the industry.

Global perspective

The light strip board LED single-sided aluminum substrate prototyping factory not only focuses on the domestic market, but also actively expands overseas markets. With a global vision, they actively integrate with international standards and participate in international competition, winning recognition and praise from customers around the world.

Strong supply chain management

The company’s supply chain management system is very complete and can effectively manage material procurement, inventory management, logistics and distribution and other aspects. They have established stable cooperative relationships with high-quality suppliers around the world to ensure a stable supply of raw materials and high-quality production of products.

Pay attention to environmental protection and social responsibility

The light strip board LED single-sided aluminum substrate prototyping factory is well aware of corporate social responsibilities. They pay attention to environmental protection during the production process, using environmentally friendly materials and energy-saving technologies to reduce the impact on the environment. At the same time, they also actively participate in social welfare activities and give back to the society.

Excellent corporate culture and team building

The company has excellent corporate culture and team building. They emphasize teamwork and innovative spirit, and encourage employees to actively participate in corporate construction and development. The company regularly organizes team activities and training to improve employees’ cohesion and centripetal force.

Excellent customer reputation and industry recognition

With excellent product quality, professional service attitude and good corporate image, the light strip LED single-sided aluminum substrate proofing factory has won high recognition from customers and widespread praise in the industry. They have customers all over the world and have a good reputation in all walks of life.

In summary, the light strip LED single-sided aluminum substrate prototyping factory relies on its professional R&D capabilities, advanced production equipment, strict quality control, professional service team, continuous innovation and R&D, global vision, and strong supply. Chain management, focus on environmental protection and social responsibility, as well as excellent corporate culture and team building and other advantages have made it a leader in the lighting industry.

PCB light bar panel led single-sided aluminum substrate manufacturing company

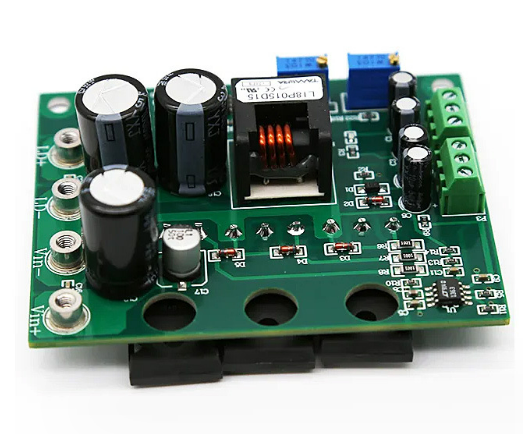

Fumax focuses on the manufacturing of PCB light strip boards and LED single-sided aluminum substrates. Fumax is a professional PCB manufacturer integrating R&D, production, sales and service, providing LED OEM/ODM services.

The company has advanced production equipment and technology and focuses on PCB R&D and production in the field of LED lighting. They are committed to providing customers with high-quality, high-performance PCB products to meet their various needs.

The company’s products are widely used in LED lighting, advertising lighting, consumer electronics and other fields, and have won the trust and recognition of many customers.