There are obvious differences between bt sheets and high TG sheets in many aspects.

The following is a detailed introduction to the difference between bt sheets and high TG sheets:

Definition and properties of bt plate and high TG plate

- BT sheet: BT sheet is a polyester sheet with excellent mechanical properties, heat resistance, chemical corrosion resistance and other characteristics. It is usually used to manufacture various mechanical parts, auto parts, electronic appliances, etc.

- High TG sheet: High TG sheet is a polymer material with a high glass transition temperature (Tg). High TG means that the material can maintain good mechanical properties and stability at high temperatures. Therefore, high TG sheets are often used to manufacture components that need to withstand high temperatures and mechanical stress, such as in aerospace, automotive, electronics and other fields.

Performance characteristics of bt plate and high TG plate

- bt plate:

(1) Excellent mechanical properties: BT plates have high strength and stiffness and can withstand large loads and pressures.

(2) Heat resistance: BT sheet has good heat resistance and can maintain stable performance within a certain temperature range.

(3) Chemical corrosion resistance: BT plates have good corrosion resistance to most chemical substances and can resist the erosion of chemical substances.

- High TG sheets:

(1) High glass transition temperature: High TG sheets have a high glass transition temperature and can maintain good mechanical properties and stability at high temperatures.

(2) Excellent mechanical properties: High TG plates have high strength and stiffness and can withstand greater loads and pressures.

(3) Good thermal stability: High TG plates can still maintain good thermal stability at high temperatures and are not easy to deform or decompose.

Application areas of bt sheets and high TG sheets

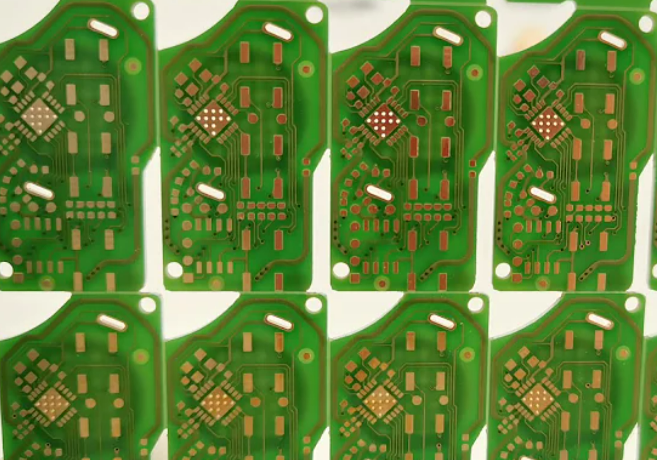

- BT sheets: BT sheets are widely used in various mechanical parts, auto parts, electronic appliances and other fields. For example, it can be used to manufacture automobile engine parts, electronic circuit boards, household appliance components, etc.

- High TG sheets: High TG sheets are mainly used to manufacture components that need to withstand high temperatures and mechanical stress, such as aerospace parts, automotive parts, electronic and electrical components, etc. For example, it can be used to manufacture aerospace engine parts, automotive engine parts, electronic chip packaging, etc.

Production technology and processing methods of bt plate and high TG plate

- BT sheet: The production process of BT sheet mainly includes polymerization, molding, processing and other links. During the polymerization process, polyester resin and other additives are used for mixing reaction; during the molding process, the resin is made into the desired shape using methods such as pressing or injection molding; during the processing process, cutting, drilling, milling and other operations are performed as needed.

- High TG plates: The production process of high TG plates mainly includes polymerization, molding, processing and other links. During the polymerization process, high-performance polymers and other additives are used for mixing reactions; during the molding process, the resin is made into the desired shape using methods such as pressing or injection molding; during the processing process, cutting, drilling, milling and other operations are performed as needed. . In addition, high TG sheets also require special post-processing, such as heat treatment, surface treatment, etc., to further improve their performance.

Market prospects and development trends

- BT sheets: With the continuous development of the machinery manufacturing industry, automobile industry and electronic and electrical industries, the market demand for BT sheets will continue to grow. In the future, with the continuous advancement and innovation of technology, the performance of BT sheets will be further improved and the application fields will continue to expand.

- High TG sheets: With the increasing demand for high-performance materials in the aerospace, automotive, electronic and electrical industries, the market prospects for high TG sheets are very broad. In the future, with the continuous advancement and innovation of technology, the performance of high TG sheets will be further improved, and the application fields will also continue to expand. At the same time, with the continuous improvement of environmental awareness, green and environmentally friendly high TG sheets will become an important trend in future development.

In short, there are obvious differences between bt sheets and high TG sheets in terms of properties, performance characteristics, application fields and market prospects. Understanding these differences can help us better select and use these two materials.