In the drive motor controller PCBA foundry, the DIP plug-in plays a key role. It can enhance the electrical performance of the PCB, provide additional mechanical support, optimize space utilization, and ensure the stability and reliability of components.

It is the key to achieving high performance. A must-have for performance, high reliability and compact design.

In the drive motor controller PCBA foundry, the DIP plug-in is an important link, and its functions are as follows:

Overview

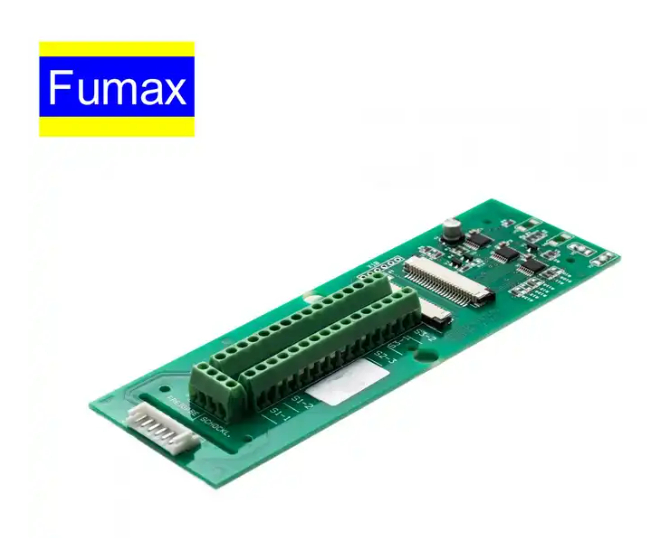

Drive motor controller PCBA foundry is a complex process involving multiple process steps. In this process, DIP plug-in is a key link. Its function is to reliably plug components on the PCB that cannot be realized through surface mount technology (SMT).

Through DIP plug-ins, the following purposes can be achieved: enhancing the electrical performance of the PCB, providing additional mechanical support, optimizing the space utilization of the PCB, and ensuring the stability and reliability of components. This article will conduct an in-depth discussion of the role of DIP plug-ins in drive motor controller PCBA foundry.

Enhance electrical performance

In the drive motor controller PCBA, some components cannot be mounted through SMT technology due to their specific electrical performance or physical characteristics. These components are usually large in size, high in power, or require large space for heat dissipation. By DIP plug-in these components, the electrical performance of the PCB can be enhanced. Specifically, through reasonable pin layout and welding, a stable and reliable electrical connection can be ensured between these components and other components on the PCB, thereby improving the performance of the entire controller.

Provide mechanical support

In some cases, the PCB driving the motor controller needs to withstand significant mechanical stress or vibration. Through DIP plug-ins, some components with strong mechanical properties (such as connectors, relays, etc.) can be inserted into the PCB to provide additional mechanical support for the entire PCB. These components can effectively disperse externally applied mechanical stress, thereby protecting the internal electronic components from damage.

Optimize space utilization

In PCB design, space utilization is an important consideration. Through reasonable DIP plug-in layout, the space utilization of PCB can be optimized, making the entire circuit board more compact. This not only reduces the size of the controller, making it more suitable for compact equipment, but also reduces production costs.

Ensure the stability and reliability of components

For some components that require large heat dissipation space, mounting through SMT may cause poor heat dissipation, thus affecting the stability and reliability of the components. Inserting these components on the PCB through DIP plug-ins can provide them with sufficient heat dissipation space to ensure that they maintain stable performance during long-term operation. In addition, a reasonable DIP plug-in layout can also reduce the risk of components shifting or falling off due to vibration or other external factors.

What are the types of DIP plug-ins for drive motor controllers

The DIP plug-ins in the drive motor controller mainly include the following types:

- In-line component packaging: In this form of packaging, electronic components are directly inserted into the reserved holes on the circuit board, and then the components are fixed on the circuit board by welding. The advantage of plug-in component packaging is high reliability, but the disadvantage is that the manufacturing cost is high and it is not suitable for miniaturized and highly integrated electronic equipment.

- SMD component packaging: In this form of packaging, electronic components are mounted on the surface of the circuit board, and the components and the circuit board are connected together by welding. The advantages of chip-type component packaging are miniaturization, lightweight, and high integration, and it is suitable for miniaturized and highly integrated electronic devices. However, the disadvantage is that the manufacturing cost is high.

- Plug-in component packaging: This form of packaging is to insert the electronic component into a removable socket, and then plug the socket into the circuit board. The advantage of plug-in component packaging is that components can be quickly replaced and easy to repair, but the disadvantage is that the manufacturing cost is high and it is not suitable for miniaturized electronic equipment.

- Press-fit component packaging: In this form of packaging, electronic components are inserted into reserved holes on the circuit board, and then the components and the circuit board are connected together by press-fitting. The advantages of crimp-type component packaging are reliable connection and fast speed, and it is suitable for high-speed, high-reliability electronic equipment. However, the disadvantage is that it requires special crimping tools and equipment.

The above are the common types of DIP plug-ins in drive motor controllers. Different packaging forms are suitable for different application scenarios and needs, and you need to choose according to the actual situation.

Summarize

To sum up, DIP plug-in plays a vital role in drive motor controller PCBA foundry. It not only enhances the electrical performance of the PCB, provides additional mechanical support, optimizes space utilization, but also ensures the stability and reliability of components. Therefore, when manufacturing drive motor controller PCBA, the application of DIP plug-in should be fully considered, and reasonable design and layout should be carried out according to actual needs.

At the same time, attention should also be paid to quality control and process optimization to ensure that the quality and reliability of DIP plug-ins meet the requirements.