The Metal Core PCB Design Guide is designed to guide engineers on how to design PCBs with metal cores to improve signal transmission quality, reduce electromagnetic interference, and improve overall performance.

The guide covers the manufacturing technology, design considerations and application advantages of metal core PCBs, and is an important reference for engineers when designing and producing metal core PCBs.

Overview

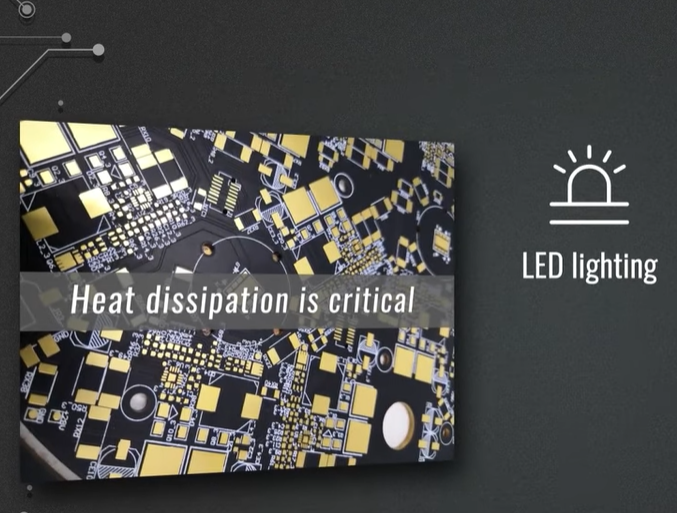

Metal core PCBs have significant advantages in specific applications, such as high heat dissipation performance, high reliability and structural stiffness.

This article will provide a detailed metal core PCB design guide to help engineers better understand and apply this special type of PCB.

Characteristics of metal core PCB

- High heat dissipation performance: Metal core PCB has excellent thermal conductivity and is especially suitable for high-power, high-heat electronic equipment.

- High reliability: Due to the strength and stability of metal core PCB, it performs well in harsh environments such as vibration, high temperature and humidity.

- Structural stiffness: Metal core PCB has high structural stiffness and is suitable for equipment that requires strong support.

Design Flow

- Requirements analysis: Clarify design requirements, such as power, size, weight, heat dissipation requirements, etc.

- Material selection: Choose the appropriate metal core material according to your needs, such as aluminum, copper, etc.

- Layout design: Arrange electronic components and circuits reasonably on the metal core, taking into account electrical performance, heat dissipation performance and mechanical strength.

- Manufacturing process: Determine the appropriate manufacturing process, such as cutting, drilling and surface treatment of the metal core.

- Testing and verification: Test and verify after completing the design to ensure that the design requirements are met.

Metal core PCB design essentials

- Component layout: On a metal core PCB, components should be distributed as evenly as possible to make full use of the thermal conductivity of the metal core. At the same time, thermal interference between components should be avoided.

- Circuit design: Consider the current size and flow direction, reasonably plan the circuit path, and reduce resistance and heat loss. For high current lines, increase the line width appropriately to reduce line resistance.

- Thermal design: The thermal design of metal core PCB is crucial. Utilize the high thermal conductivity of the metal core to improve heat dissipation efficiency by rationally arranging heat dissipation holes and heat sinks.

- Mechanical strength: Metal core PCB has high mechanical strength, but its load-bearing capacity and impact resistance still need to be considered in the design. Carry out reinforcement design according to actual needs to ensure the stable operation of the equipment.

- Signal integrity: Although metal core PCBs are mainly used in high-power and high-heat scenarios, signal integrity still needs to be paid attention to in the design. Reasonably plan the layout and width of signal lines to reduce signal delay and distortion.

- Grounding design: In order to ensure the electromagnetic compatibility of the equipment, the grounding network should be designed reasonably. Utilize the conductivity of the metal core to achieve effective grounding and reduce electromagnetic interference.

- Cost considerations: Although metal core PCBs have many advantages, their costs are usually higher than traditional FR4 PCBs. During the design process, cost factors should be fully considered to avoid unnecessary waste.

- Repairability: When designing metal core PCBs, consider possible future repair needs. Provides easily replaceable components and modules to reduce maintenance costs and difficulty.

- Environmental adaptability: For equipment that needs to operate in harsh environments, the high stability and durability of metal core PCBs make it an ideal choice. However, the impact of environmental factors on the metal core, such as corrosion and oxidation issues, also needs to be considered.

- Standardization and modularization: Use standardized design and modular components as much as possible to facilitate production and maintenance, reduce production costs and improve production efficiency.

- Redundancy and backup: For key circuits and components, redundant design and backup measures should be considered to improve the reliability and stability of the system.

- Human-computer interaction: Consider human-computer interaction factors during the design process to make the layout and appearance of the PCB meet ergonomic requirements and improve the ease of use and user experience of the product.

- Environmental protection and sustainable development: In the design process of metal core PCB, environmentally friendly materials and processes should be selected as much as possible to reduce the negative impact on the environment. At the same time, consider the recyclability and reusability of materials to promote sustainable development.

- Testing and verification: Carry out sufficient testing and verification during the design process to ensure that the function, performance and reliability of the metal core PCB meet the design requirements. This helps reduce the workload of late modification and optimization, and reduces development costs and time.

Metal Core PCB Design Summary

Metal core PCB has certain complexity in design, production and application, and its characteristics and application scenarios need to be fully understood.

By following the above design guidelines, engineers can better grasp the design points and methods of metal core PCBs and provide stable and reliable solutions for various applications.

With the continuous development and innovation of technology, metal core PCB will be widely used in more fields, bringing more possibilities to the development of electronic equipment.

Provider of PCB assembly and manufacturing services

A service provider that provides PCB assembly and manufacturing, committed to providing customers with efficient and professional PCB assembly and manufacturing services.

They have advanced production equipment and a professional technical team that can quickly respond to customer needs and ensure product quality and delivery time.

Choose them and you will receive high-quality PCB assembly and manufacturing services to provide strong support for your product development and production.