PCB customization factory in Brazil: technology, quality and service

Brazil’s PCB customization factories enjoy a global reputation for their exquisite craftsmanship, excellent quality and efficient services to meet the growing needs of the electronic equipment market.

Advanced technology

Brazil’s PCB customization factory has introduced advanced production equipment and adopted the most advanced process technology to ensure the high quality of PCBs. They have multi-layer board manufacturing capabilities and can meet various difficult and demanding customization needs.

These factories pay attention to environmental protection in production and use environmentally friendly materials and processes to ensure that products comply with international environmental protection standards.

Strict quality control

Brazil’s PCB customization factories adhere to strict quality control standards. From raw material procurement to finished product delivery, every link undergoes strict quality testing. This ensures that each PCB has ultra-high reliability and stability, providing a strong guarantee for customers’ product quality.

Excellent service

Brazil’s PCB customization factory provides one-stop service, from design, production to after-sales, and maintains close communication with customers throughout the process to ensure that various customer needs are met. They also provide 24-hour online services to answer customer questions and provide technical support at any time. In addition, they also provide rapid prototyping services, shortening product time to market and winning valuable time for customers.

In general, Brazil’s PCB customization factories have become leaders in the global PCB industry with their advanced technology, strict quality control and excellent services. They provide customers with high-quality, high-efficiency, cost-effective products and services, and have won widespread praise and trust.

Creativity

Brazilian PCB customization factories also attach great importance to innovation. They continuously develop new materials, processes and technologies to meet changing market needs. These innovations allow Brazil’s PCB customization factories to maintain a leading position in global competition.

Global perspective

Brazil’s PCB customization factories not only have extensive influence in Brazil, but are also actively exploring international markets. They have established close cooperative relationships with customers around the world and provide customized PCB products to meet the needs of different countries and regions. This has made Brazil’s PCB customization factories enjoy a global reputation and become the preferred partner for many well-known brands.

Sustainable development

PCB customization factories in Brazil also attach great importance to sustainable development. They adopt a series of environmental protection measures during the production process, such as using environmentally friendly materials, optimizing production processes, reducing waste emissions, etc., to reduce their impact on the environment. In addition, these factories also actively participate in social welfare activities, give back to the society, and promote sustainable development of the community.

To sum up, Brazil’s PCB customization factories occupy an important position in the global PCB industry with their advanced technology, strict quality control, excellent service, innovation capabilities, global vision and sustainable development concept.

They provide customers with high-quality, high-efficiency, cost-effective products and services, and have made important contributions to the development of the global electronic equipment industry.

PCB factories serving Brazil

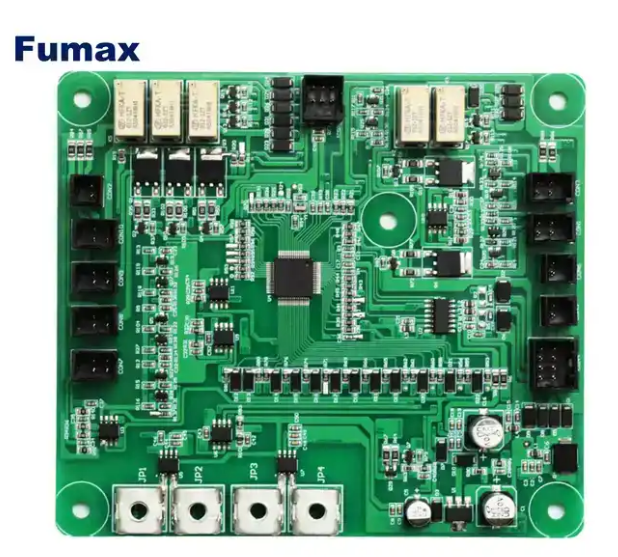

Brazilian PCB factory with exquisite craftsmanship and excellent quality. Relying on advanced production equipment and technology, we are committed to providing efficient and reliable customized services.

Strict quality control ensures the ultra-high quality of each PCB. Meet all kinds of difficult and demanding customization needs and protect the quality of customers’ products.

Fumax is a Chinese PCB factory focusing on global PCB assembly and PCB customization services.

Brazilian PCB Factory FAQs

In Brazilian PCB factories, common production problems may include improper solder pad design, improper part orientation, automatic plug-in bending feet, etc. These problems may cause PCB short circuits, reduced electrical performance, etc.

To solve the PCB short circuit problem, measures such as changing the circular pad to an oval shape, increasing the distance between points, and appropriately modifying the direction of the part to make it perpendicular to the tin wave can be taken. In addition, attention should also be paid to problems such as too large holes in the substrate, too low solder furnace temperature, poor solderability of the board, failure of the solder mask, and contamination of the board.

When laying out the board, the line density and the number of vias should be reduced as much as possible to improve the electrical performance of the board. In addition, high-precision resistors such as constantan resistors can be selected to reduce resistance errors and improve electrical performance.

The sampling resistor can use PCB traces as the sampling resistor, but attention should be paid to the heat dissipation performance, accuracy, stability and reliability of the PCB. For problems with high power and low accuracy, you can use higher-precision resistors or use multiple resistors in parallel.

The analog ground and digital ground should be connected with the VSS of the microcontroller as the reference point. Connecting analog ground and digital ground to the large filter capacitor of the power supply can reduce interference and noise.

There are requirements for the spacing between strong and weak electrical components, and a certain safety distance should be ensured to reduce problems such as electromagnetic interference and signal coupling. Specific spacing requirements can be determined based on the specific application and circuit board design standards.

Reasonable layout and separation of high current ground and digital ground can effectively reduce interference. In addition, selecting appropriate decoupling capacitors and low-pass filter resistor and capacitor parameters can also reduce interference.