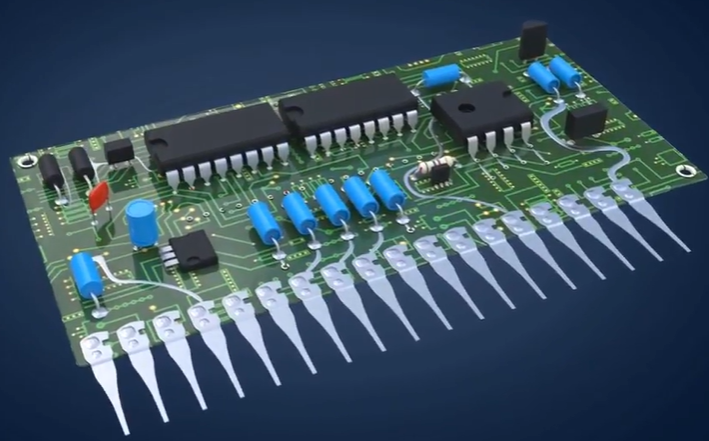

Rigid-soft board PCB assembly is to combine flexible circuit boards and rigid circuit boards through processes such as lamination to form circuit boards with special properties.

In Brazil, there are many rigid-flex board PCB assembly and manufacturing manufacturers, among which the more well-known ones are:

Fumax

Shenzhen Fumax Technology Co., Ltd. was established as a rigid-flex board PCB assembly manufacturer in China. Focus on flexible circuit board (FPC) and rigid circuit board (PCB) assembly and manufacturing services.

In the soft-hard board PCB assembly business, FPC production equipment and PCB production equipment are usually required. First, electronic engineers will draw the circuit and shape of the flexible combination board according to the needs, and then send it to the factory that can produce flexible and rigid combination boards.

After CAM engineers process and plan the relevant documents, they will arrange the FPC and PCB production lines required for FPC production line production to produce PCBs.

The soft-hard board has the characteristics of both FPC and PCB, so it can be used in some products with special requirements. It has both a certain flexible area and a certain rigid area, which is beneficial to saving the internal space of the product and reducing the number of finished products. Volume is of great help in improving product performance.

Condor Techmologia em Eletrônica

This is a company that provides PCB design, production and assembly services, headquartered in the state of Sao Paulo. The company has extensive experience in rigid-flex board PCB manufacturing and is able to provide high-quality products and professional services.

InterBoard

This is a company specializing in PCB design and manufacturing, headquartered in the state of São Paulo. The company has advanced production equipment and processes and is able to provide manufacturing and assembly services for rigid-flex board PCBs.

Flex Tech do Brasil

This is a multinational company engaged in the production and assembly of flexible circuit boards, headquartered in the state of Sao Paulo. The company has modern production lines and advanced production equipment, capable of providing high-quality rigid-flex board PCB products.

These manufacturers have advanced production equipment and processes and can provide high-quality rigid-flex board PCB products and services.

If you need assembly and manufacturing services for rigid-flex board PCB, you can choose the appropriate manufacturer to cooperate according to your needs.

PCB manufacturers you can choose

Rigid-flex PCB assembly manufacturers have professional technology and equipment and can provide high-quality Rigid-flex PCB assembly services. These manufacturers have advanced production equipment and processes to ensure product quality and delivery stability.

At the same time, these manufacturers also have professional technical teams and technical support, able to provide customers with comprehensive technical support and solutions to meet customer needs.

Fumax PCB manufacturer service business includes PCB board production, board copying, board modification, schematic design, proofing, rapid production and mass production, assembly, technical consultation and support, logistics and distribution, and after-sales service.

Rigid-Flex PCB Assembly FAQs

We adopt strict quality assurance measures, including raw material inspection, process control, finished product inspection, etc., to ensure the quality and stability of our products.

We use advanced production processes and technologies, including surface mounting technology, welding technology, testing technology, etc., to ensure product quality and stability.

We provide various types of rigid-flex board PCB assembly services, including single-sided boards, double-sided boards, multi-layer boards, etc., as well as various customized PCB assembly services.

Depending on the specific order and product type, our delivery times may vary. We will negotiate with you to determine the specific delivery date and ensure on-time delivery.