Turnkey PCB Assembly Service is a comprehensive one-stop service covering the entire process from PCB design to finished product assembly.

The provider of this service is usually a Contract Manufacturer, who undertakes all aspects from design to production, ensuring that the final product meets specifications and is delivered to the customer on time.

Below is a detailed introduction about turnkey printed circuit board assembly services:

Design service

Contract manufacturers provide professional PCB design services to ensure designs meet performance, reliability and cost requirements.

Manufacturers work closely with customers to design PCBs according to customer needs and specifications, including all design-related tasks such as layout, routing, component selection and placement.

Component procurement

The manufacturer is responsible for purchasing the required electronic components, communicating with suppliers based on the component list provided by the customer, and ensuring the timely supply and quality reliability of all components. Manufacturers often assist customers with the logistics and inventory management of component procurement to reduce the complexity of supply chain management.

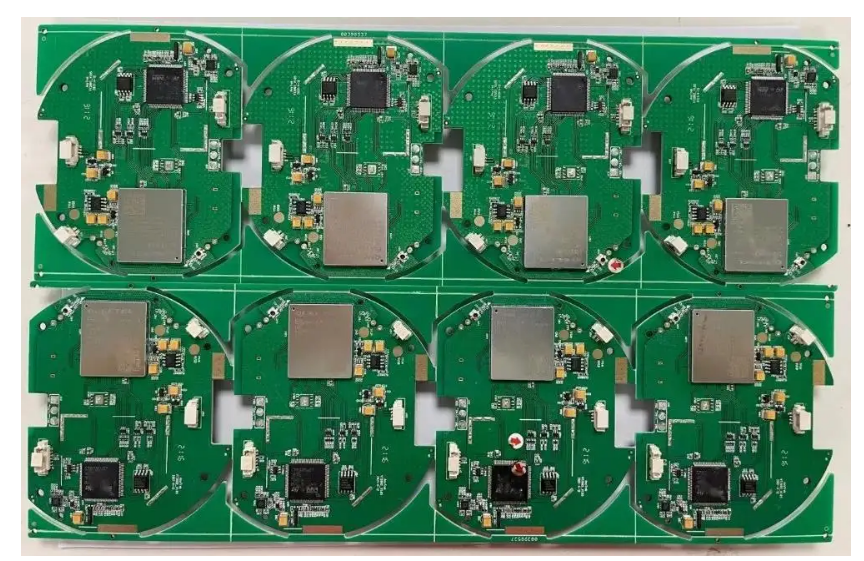

Assembly and testing

Manufacturers carry out PCB assembly and testing, including welding, inspection, debugging, etc., to ensure the normal function of the circuit board. Manufacturers use automated equipment to improve production efficiency and product quality. At the same time, they will also provide test reports and quality control documents to ensure that the products meet quality requirements.

Quality assurance

The manufacturer conducts a series of strict quality inspection and control measures to ensure that the final product meets the customer’s quality requirements. This includes visual inspection, functional testing, environmental testing and other aspects to ensure the reliability and stability of the product.

Packaging and shipping

Manufacturers package and transport products according to customer needs, choosing appropriate packaging materials and methods to ensure that products are not damaged during transportation. The final product is delivered to the customer’s designated location on time, providing a complete turnkey service experience.

Benefits of turnkey PCB assembly services include:

Save time

Customers can focus on their core business without spending a lot of time in the design and production process. By offloading production and assembly tasks to contract manufacturers, customers can accelerate their time to market.

Risk reduction

Since manufacturers bear most of the design and production work, customers can reduce various risks encountered during the production process. The manufacturer has extensive experience and a professional technical team that can deal with problems that may arise during the production process and ensure the quality and reliability of the final product.

Improve quality

Professional manufacturers have advanced equipment and processes to ensure the quality and reliability of the final product. They adopt strict quality control measures and conduct quality testing in accordance with industry standards and customer requirements to ensure that products meet specifications.

Simplify the process

Customers only need to work with one supplier, which can simplify the entire supply chain management process. Contract manufacturers provide one-stop services, with professional teams responsible for everything from design to production, testing and shipping, reducing the complexity of coordination between multiple suppliers for customers.

Quick response

Contract manufacturers often have flexible production capabilities that can quickly adapt to market changes and customers’ special needs. They can quickly respond to customer feedback and requirements and adjust production plans in a timely manner to meet urgent orders or customized needs.

Overall, turnkey printed circuit board assembly services provide customers with a one-stop solution from design to production, helping customers save time, reduce risks, improve quality, streamline processes and respond quickly to market changes.

Choosing a reliable contract manufacturer is key to successfully implementing a turnkey project, and customers need to carefully evaluate and select partners to ensure the smooth completion of the project.