Overview of Brazilian PCB Industry

Brazil, the largest economy in South America, has achieved significant development in electronics manufacturing in recent years.

Especially in the field of printed circuit board (PCB) assembly and design, Brazil has become a production and R&D base that cannot be ignored.

As the basic component of electronic equipment, PCB’s quality and performance directly affect the stability and reliability of the final product.

Therefore, Brazil’s PCB industry has strict requirements and pursuits in terms of technology and quality.

PCB design process and standards

- Design process: In Brazil, the PCB design process usually includes steps such as requirements analysis, schematic design, circuit layout, wiring, simulation verification and final output. Designers need to work closely with customers to ensure that the design meets the product’s performance, cost and production requirements.

- Design standards: Brazil’s PCB design follows internationally accepted standards and specifications, such as IPC standards, IPC-A-600, etc. These standards ensure the design quality and production consistency of PCBs and provide a strong guarantee for the global market competitiveness of products.

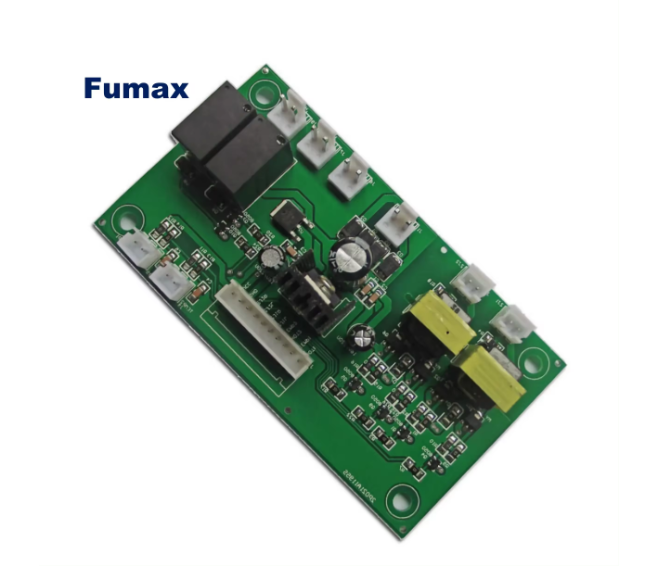

PCB assembly processes and technologies

- Assembly process: Brazil’s PCB assembly process covers all aspects from component selection, patching, welding, testing to final assembly. Among them, the application of automation equipment and intelligent manufacturing technology is becoming increasingly widespread, improving production efficiency and product quality.

- Assembly technology: In terms of assembly technology, Brazil’s PCB industry focuses on technological innovation and research and development. For example, advanced surface mount technology (SMT), laser welding technology, automatic optical inspection (AOI), etc. are used to ensure high precision, high reliability and high production efficiency of products.

Challenges and opportunities in the Brazilian PCB market

- Challenges: The Brazilian PCB market is facing challenges such as rising costs, rapid technological updates, and increasing environmental protection requirements. At the same time, international competitive pressure and diversified market demands have also put considerable pressure on industrial development.

- Opportunities: With the rapid development of the global electronics industry, especially the rise of emerging fields such as 5G, Internet of Things, and artificial intelligence, the Brazilian PCB industry has ushered in huge market opportunities. In addition, the government’s support and preferential policies for the electronics manufacturing industry have also provided strong support for industrial development.

The future outlook of the Brazilian PCB industry

Looking to the future, the Brazilian PCB industry will continue to maintain a steady development trend. In terms of technology, with the widespread application of technologies such as smart manufacturing, automation and artificial intelligence, PCB design and production efficiency will be further improved. At the same time, environmental protection and sustainable development will become important directions for industrial development, promoting the industry to develop in a green, low-carbon, and circular direction.

In terms of market, with the continuous expansion of the global electronics market and the rapid development of emerging fields, the Brazilian PCB industry will usher in more market opportunities. Especially in the fields of new energy vehicles, 5G communications, smart homes and other fields, the Brazilian PCB industry is expected to achieve greater breakthroughs and development.

In general, Brazil’s PCB assembly and design industry has significant advantages and potential in both technology and market.

Facing future challenges and opportunities, Brazil’s PCB industry needs to continue to strengthen technological innovation and market development capabilities to cope with increasingly fierce market competition and changing market demands.

At the same time, the government and enterprises also need to strengthen cooperation and investment to provide strong guarantee and support for the sustainable development of the industry.

The above content is only a brief introduction. If you need a more in-depth understanding and analysis, it is recommended to consult professional reports and research materials in related industries.

At the same time, you can also contact and communicate with local PCB companies and related institutions in Brazil to obtain more detailed and accurate information.