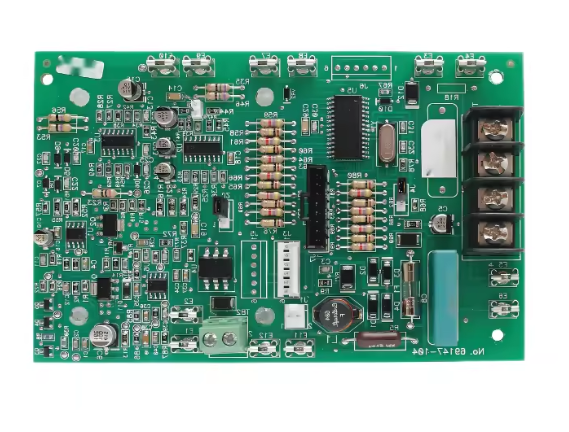

The motor drive module is the core component that controls the operation of the motor. Its circuit design directly affects the performance, stability and safety of the motor.

Therefore, it is particularly important to formulate a complete set of motor drive module circuit design specifications. This article will give a detailed introduction to the motor drive module circuit design specifications from the basic principles of circuit design, key component selection, protection circuit design, thermal design, electromagnetic compatibility design, and testing and verification.

Basic principles of circuit design

- Safety: Circuit design should comply with relevant safety standards to ensure personal and equipment safety under normal working conditions and abnormal situations.

- Reliability: The circuit should have high reliability and be able to operate stably for a long time in harsh environments.

- Efficiency: Circuit design should fully consider efficiency to reduce energy loss and improve the operating efficiency of the motor.

- Scalability: The circuit design should have a certain degree of scalability to facilitate subsequent function upgrades and expansions.

Key component selection

- Power switching device: Select the appropriate power switching device according to the power and driving mode of the motor, such as IGBT, MOSFET, etc.

- Control chip: Choose a control chip with stable performance and complete functions to achieve precise control of the motor.

- Power supply filtering devices: Select appropriate power supply filtering devices, such as capacitors, inductors, etc., to reduce the impact of power supply noise on the circuit.

- Passive components such as resistors, capacitors, and inductors: Select appropriate passive components based on circuit needs and performance requirements.

Protection circuit design

- Overcurrent protection: Design an overcurrent protection circuit to prevent the motor or circuit from being damaged due to overcurrent.

- Overheating protection: Design an overheating protection circuit to monitor the temperature of the motor and circuit to prevent failures caused by overheating.

- Overvoltage/undervoltage protection: Design an overvoltage/undervoltage protection circuit to ensure that the motor operates within a suitable voltage range.

- Short circuit protection: Design a short circuit protection circuit to prevent short circuits in the circuit from causing malfunctions.

Thermal design

- Selection of heat dissipation methods: Choose the appropriate heat dissipation method according to the power of the motor and the working environment, such as natural cooling, fan cooling, liquid cooling, etc.

- Thermal resistance calculation: By calculating the thermal resistance of the circuit, determine the size and material of the radiator to ensure that the motor and circuit will not overheat under normal operating conditions.

- Temperature monitoring: Set temperature monitoring points at key parts to monitor the temperature of the motor and circuit in real time to ensure stable operation of the system.

Electromagnetic compatibility design

- Electromagnetic interference suppression: Reduce the electromagnetic interference generated by the circuit through reasonable wiring and use of shielding materials to avoid affecting surrounding equipment.

- Anti-interference ability: Improve the anti-interference ability of the circuit to ensure that the circuit can work normally in complex electromagnetic environments.

Testing and Validation

- Functional test: Carry out functional test on the motor drive module to ensure that all functions are normal.

- Performance testing: Perform performance testing on the motor drive module, such as efficiency testing, temperature rise testing, etc., to ensure that it meets the design requirements.

- Reliability test: Conduct a long-term reliability test on the motor drive module to simulate the operation in a harsh working environment to ensure that the circuit has high reliability.

Summarize

The motor drive module circuit design specification is a complete set of circuit design guidelines, which covers the basic principles of circuit design, key component selection, protection circuit design, thermal design, electromagnetic compatibility design, and testing and verification.

Following these specifications for motor drive module circuit design can ensure the safety, reliability, efficiency and scalability of the circuit, and improve the operating performance and service life of the motor.

At the same time, these specifications also provide strong technical support for the design, production and maintenance of motor drive modules.