China leads the global PCB assembly (PCBA) industry with its exceptional advantages. From market size to manufacturing capabilities, labor costs, government support, and supply chain superiority, China excels in numerous aspects, making it a powerhouse in the field.

1.Market Size

China boasts a vast market size, providing ample opportunities for PCBA manufacturers. With over 1.4 billion people, the country’s domestic demand for electronic products drives the industry’s growth, attracting both local and international companies.

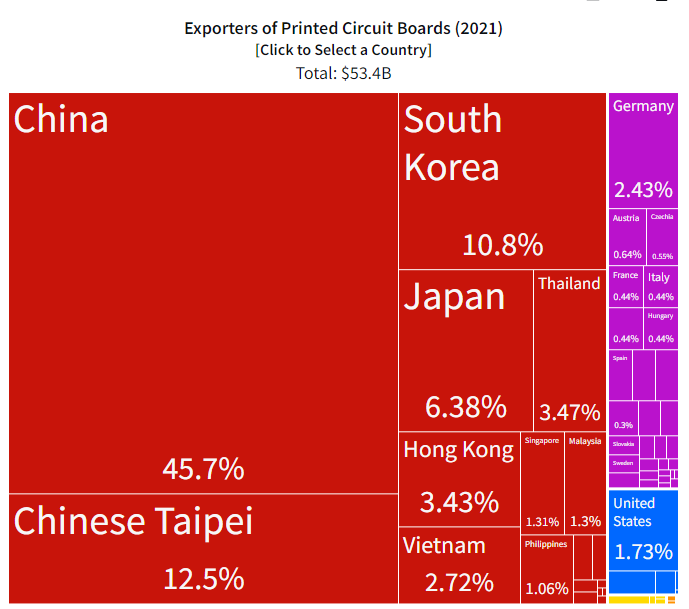

PCBs are widely known as the basis of electronic products, and China is currently the largest exporter of PCBs in 2021, accounting for 45% of global exports.

2.Advanced manufacturing capabilities.

The country’s advanced manufacturing capabilities contribute significantly to its success in PCBA. Equipped with cutting-edge technology, state-of-the-art machinery, and a well-developed supply chain, Chinese factories ensure efficient production processes, high-quality output, and shorter lead times.

3. China pcba cost-effective solution

China’s cost-effective labor further strengthens its PCBA dominance. While labor costs have risen, China remains competitive compared to other countries. Its abundant and skilled labor force efficiently handles labor-intensive tasks such as component assembly and soldering.

Despite lower labor costs in Southeast Asian countries such as Vietnam and Thailand, the modern PCB industry increasingly relies on highly automated and technology-intensive production models. China has the world’s largest PCB factory, Asia’s most developed electronic components trading network, as well as a sound industrial chain (metal smelting and processing, injection molding, sheet metal, casting, etc.). This means that customers can find suppliers that produce all their parts in one country, not just the PCBA.

4. Government Support

The Chinese government provides unwavering support to the PCBA industry. Through various initiatives like tax incentives and subsidies, the government fosters growth, encourages foreign investment, innovation, and research and development activities. This proactive support enhances China’s competitiveness in the global market.

Taking Stock of China’s Semiconductor Industry

by Semiconductor Industry Association

5. Chia PCBA Supply Chain Advantage

China’s supply chain advantage, especially in electronic components, propels its PCBA industry forward. The country’s well-established network of suppliers, distributors, and manufacturers ensures streamlined procurement, efficient inventory management, and access to high-quality components.

With a strong manufacturing capacity, China offers a wide range of electronic components, including chips, resistors, capacitors,etc.

Its cost-effectiveness, integrated supply chain, and robust R&D capabilities contribute to its competitiveness. Additionally, China’s vast market size creates opportunities for manufacturers and suppliers alike. Overall, China excels in manufacturing, cost efficiency, supply chain integration, innovation, and market scale in the electronic components sector. These strengths position China as a key player in the global supply chain.

6.Summary

In conclusion, China’s leadership in the global PCB assembly industry arises from its extensive market size, advanced manufacturing capabilities, cost-effective labor, government support, and supply chain superiority. These factors make China an attractive destination for PCBA manufacturing, securing its position as a global powerhouse in the industry.