Custom PCBA demand is increasing, with the popularity of 5G technology, more and more electronic products, especially consumer electronic products with communication modules, need to update the PCBA to achieve new functions. Large companies often design and manufacture their own products. But not every company has factories and teams of engineers. In fact, maintaining a production department and an engineering department is very expensive. Therefore, outsourcing PCBA or even finished product manufacturing is more efficient choice. So, how to custom PCBA? This article will give you some inspiration.

Step1. Summarizing Project Information

Before contacting your supplier, make sure you have all the project information. Suppliers will need info following for quoting PCBA:

- Gerber

- BOM

- PCB specification

- Quotation quantity

- Other special requirements (special layer stack, special surface treatment, special drilling, etc.)

Once you have gathered these information, you can contact your supplier and request for a quote.

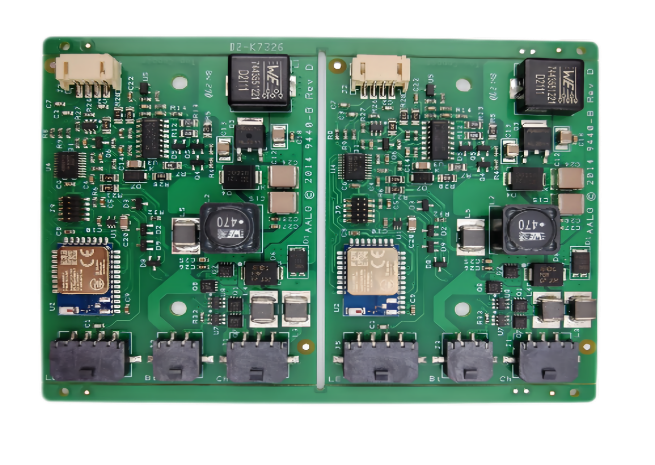

Of course, you can also provide the schematic, PCBA pictures and even samples to your supplier. The more details they have, the more accurate the supplier’s quotation will be.

So, “what if I don’t have a design?”

Suppliers with engineering skills may be able to help you. You can ask your supplier if they can clone and mass-produce PCBA based on your samples, or even design a new product based on your functional requirements. Some suppliers, like Fumax, can provide one-stop services, from electronic design to mass production.

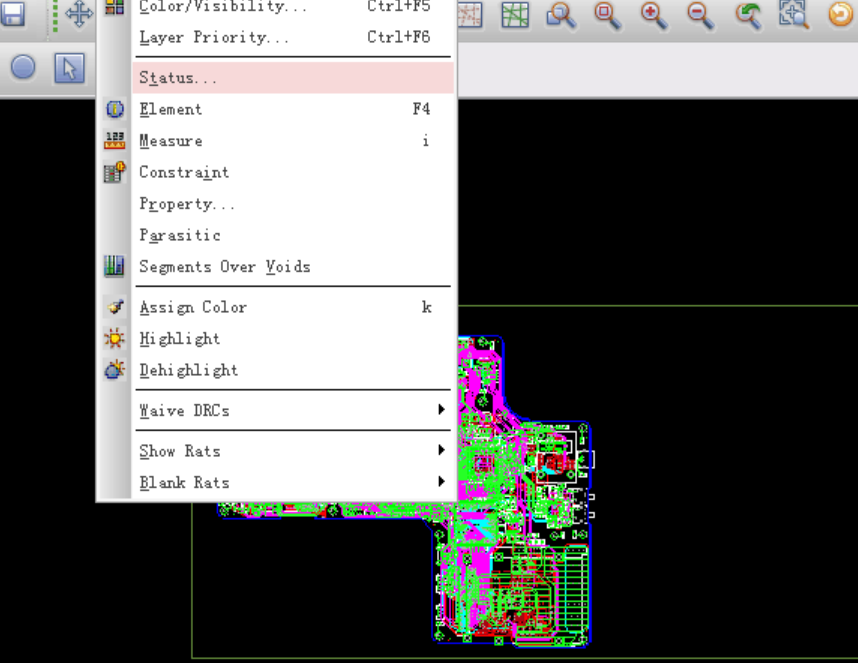

Step2. Discussion and details about custom PCBA

Different projects will have different requirements. Remember the special requirements mentioned in step 1? That’s going to be the focus of this session. Equipment and engineering capacity will not be identical between suppliers. Make sure your supplier has the equipment to produce and assemble major components and the corresponding testing capabilities.

For example, some vendors don’t have X-ray testing equipment, which means they can’t check the mount quality of BGA chips. Outsourcing this step will increase risk and cost. That’s what you don’t want.

Also, pay attention to time taken by the supplier to quote. Motherboards often contain hundreds or even thousands of components, and they are supplied by different manufacturers. To ensure the quality of the components, the supplier sourcing team will make multi-inquiries from these manufacturers or authorized suppliers to match customer’s requirement, which usually takes 2-3 business days, and even longer for some scarce chips. Therefore, if your project is complex and the supplier quotes you within few hours, double check with them.

Video meeting or even live workshop auditing is a very effective method. You can meet the project leader in person and gain insight into the supplier’s production capabilities. Responsible vendors will glad to make further contact with you because they want to work with you for the long term.

Step3. Sample and feedback

After confirming the PI, the supplier will usually provide pre-production samples for your approval. At the same time, the supplier will also confirm with you the logistics plan of the bulk goods. Make sure they understand your shipping requirements, including details on packaging, customs clearance, taxes, etc.