Designing PCBs for Internet of Things (IoT) products, especially those incorporating Ultra-Wideband (UWB) modules, involves a unique set of challenges and considerations. These include ensuring optimal electrical performance, thermal management, mechanical strength, manufacturability, environmental compliance, and cost-effectiveness. This article delves into the specific factors engineers need to consider when designing PCBs for IoT products with […]

Posts with the oem pcba tag

OEM PCBA is the original equipment manufacturer’s PCB board assembly, that is, the PCB board processed by the original equipment manufacturer. This means that the brand owner does not directly produce products, but entrusts OEM electronic processing PCBA processing companies to perform one-stop electronic processing. The brand producer only needs to provide product design and marketing.

Unveiling Circuit Card Assembly 2024: From PCB Manufacturing to Board Assembly

Hey there, tech enthusiasts! Get ready to dive deep into the fascinating world of circuit card assembly. In this comprehensive guide, we’ll take you through every meticulous step of the process, from PCB manufacturing to the final assembly of the board. So grab your coffee, settle in, and let’s explore the intricate journey of bringing […]

PCB Pad Design Guideline(2)

4.3.9 When designing multilayer boards, attention should be paid to components with metal casings that are in plug-in packages and make contact with the printed circuit board. The top layer pads must not be opened. They must be covered with green oil or silkscreen ink (such as two-pin crystals, three-pin LEDs). 4.3.10 When designing and […]

Key to Quality: First Article Inspection in Electronics Manufacturing

In the fast-paced world of electronic manufacturing, ensuring quality and efficiency is paramount. Among the arsenal of quality control measures, First Article Inspection (FAI) stands out as a crucial step, particularly in the intricate process of printed circuit board (PCB) assembly. Let’s delve into why FAI is indispensable in electronic manufacturing and PCB assembly processes. […]

Optimizing PCB Assembly: A Seamless Customer Order Journey

In the dynamic landscape of electronics manufacturing, efficient execution of customer orders is paramount. At our state-of-the-art facility, we pride ourselves on seamlessly orchestrating the production process from inception to delivery, ensuring client satisfaction at every step. In this article, we delve into the intricate journey of a customer’s order, shedding light on how PCB […]

Will the PCB assembly factory provide BGA components?

Will the BGA assembly factory provide BGA components?

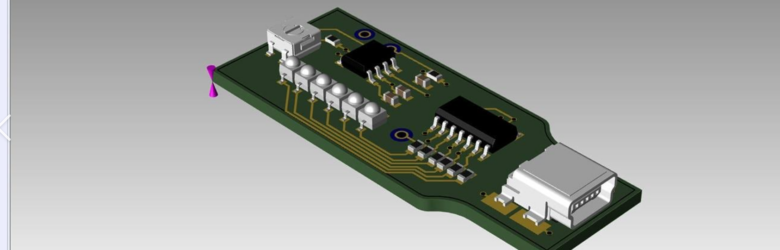

PCB OEM factory water pump controller hardware system design

PCB OEM factory water pump controller hardware system design

DIP plug-in and process flow analysis of DIP plug-in processing

DIP plug-in and process flow analysis of DIP plug-in processing

China’s large industrial PCB assembly factory manufacturing process

China’s large industrial PCB assembly factory manufacturing process

Top 6 water pump control module PCB assembly customization factories

In China, the ranking of the top 6 water pump control module PCB assembly customization factories is for reference only because it involves a comprehensive evaluation of multiple factors, such as technical strength, production scale, product quality, customer reputation, etc. However, according to relevant information about the water pump control module PCBA (PCB assembly) industry, […]