In the previous article, our PCB engineers have already explained the BGA assembly process. The original title is “PCB assembly engineers explain the BGA assembly process.” Next, we will introduce whether the PCB factory provides BGA components when doing BGA assembly.

First, let’s talk about some common BGA problems.

What does a BGA assembly factory do?

The BGA assembly factory mainly performs BGA welding processing, which is welding, rework and other operations on BGA chips. BGA welding processing is an electronic processing service that involves welding, rework and other operations on BGA chips to achieve the manufacturing and repair of electronic products. During the BGA welding process, the BGA chip needs to be strictly inspected and tested to ensure the welding quality and normal chip function. In addition, BGA assembly factories may also provide other electronic processing services, such as PCB copying, SMT patching, etc.

What are BGA components?

BGA components are components that use spherical leads and array packaging. Tin balls are made on the bottom of the packaging substrate as the interface of the circuit board to connect to the circuit board. BGA components are suitable for surface mount components and have the characteristics of large pin spacing and large pin count. High pin count, smaller assembly area, and larger pin spacing can improve the reliability of the circuit. The structure of BGA components includes core cavity, base, leads and caps, and ball pins. The assembly of BGA components can be achieved through SMT applications.

Will the BGA assembly factory provide BGA components?

BGA assembly plants do not necessarily provide BGA components. The BGA assembly factory mainly provides BGA welding processing services, that is, welding, rework and other operations on BGA chips. Although some BGA assembly plants may provide BGA components, not all BGA assembly plants sell BGA components. If you need to purchase BGA components, you may need to contact a specialized electronic component supplier or distributor.

BGA assembly OEM/ODM factory in China

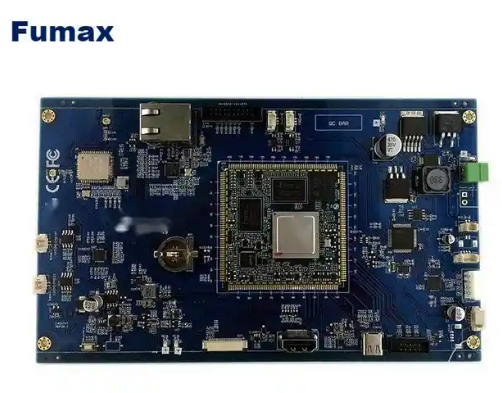

In China, Fumax is a BGA assembly OEM/ODM factory, an electronic processing enterprise specializing in BGA welding processing and OEM processing.

These factories usually have advanced production equipment, technical strength and rich production experience, and can provide a series of services from product design and manufacturing to finished product assembly.

The main business of BGA assembly OEM/ODM factory includes:

BGA welding processing

Perform welding, repair and other operations on BGA chips to ensure the welding quality and normal chip function.

OEM and material processing

Provide customers with one-stop electronic processing services, including PCB copying, SMT patching, component replacement, production and debugging of functional prototypes, etc.

Customized services

Provide customized product design and manufacturing services according to customer needs to meet customers’ specific needs.

The advantages of BGA assembly OEM/ODM factories are:

- Strong technical strength: It has advanced production equipment and technical strength, and can provide high-quality BGA welding processing and OEM processing services.

- Rich experience: With rich production experience and technology accumulation, we can provide customers with more reliable products and services.

- Customized services: Able to provide customized product design and manufacturing services according to customer needs to meet customers’ specific needs.

- Cost-effectiveness: Through large-scale production and high-efficiency operations, we can provide more competitive prices and cost-effectiveness.

If you need to find a BGA assembly OEM/ODM factory, you can learn about and compare through Internet searches (search PCB manufacturer fumax on Google), industry exhibitions, professional forums, etc.

At the same time, it is recommended that you conduct an on-site inspection of the factory to understand its production equipment, technical strength, quality management system, etc., to ensure that you choose the right partner.

If you have needs, please contact us, we are a PCB manufacturer in China, the PCB assembly factory is located in Bao’an District, Shenzhen, China.