In the dynamic landscape of electronics manufacturing, efficient execution of customer orders is paramount. At our state-of-the-art facility, we pride ourselves on seamlessly orchestrating the production process from inception to delivery, ensuring client satisfaction at every step. In this article, we delve into the intricate journey of a customer’s order, shedding light on how PCB assembly, Surface Mount Technology (SMT), and Dual In-line Package

Understanding Customer Requirements: The journey begins with a thorough understanding of the customer’s requirements. Our sales and engineering teams collaborate closely with the client to comprehend their specifications, volume expectations, and timeline constraints. This initial stage sets the foundation for a successful partnership, ensuring that all parties are aligned on project objectives.

Order Processing and Planning: Upon receiving the customer’s order, our dedicated team initiates the order processing phase. Detailed attention is given to every aspect, from component procurement to production scheduling. Our procurement specialists leverage a vast network of trusted suppliers to source high-quality materials at competitive prices, ensuring cost-effectiveness without compromising on quality. Simultaneously, our production planners meticulously schedule each stage of the assembly process to optimize efficiency and meet delivery deadlines.

First Article Inspection (FAI): Before proceeding further, it’s essential to conduct a First Article Inspection (FAI) to validate the integrity and functionality of the assembled components. This crucial step involves examining a representative sample from the production run to ensure compliance with specifications and quality standards. By performing FAI, we proactively identify any potential issues or deviations early in the process, allowing for timely corrective action and preventing costly rework downstream. Our commitment to thorough inspection and validation underscores our dedication to delivering flawless products that exceed customer expectations

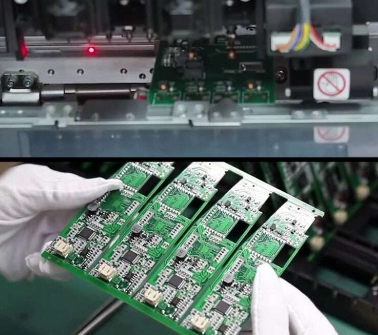

PCB Assembly and SMT Integration: Central to our operations is the Printed Circuit Board (PCB) assembly process, where intricate electronic components are mounted onto the PCB substrate. Our facility boasts cutting-edge Surface Mount Technology (SMT) lines equipped with advanced pick-and-place machines, capable of high-speed and precision component placement. Through automated optical inspection (AOI) and X-ray inspection, we ensure the integrity of solder joints, guaranteeing superior quality and reliability.

DIP Component Integration: In cases where Through-Hole Technology (THT) components are required, our skilled technicians handle Dual In-line Package (DIP) insertion with precision and expertise. Each component is meticulously soldered onto the PCB using industry-leading techniques, ensuring optimal electrical conductivity and mechanical stability. Our commitment to quality extends to every solder joint, as we employ rigorous testing protocols to detect any defects or inconsistencies.

Box Building&Final Assembly(optional): In addition to PCB assembly, our comprehensive services extend to box building and final assembly, providing a one-stop solution for our clients’ manufacturing needs. Our skilled technicians adeptly handle the integration of electronic components into enclosures or chassis, ensuring seamless functionality and aesthetic appeal. Whether it’s the assembly of complex electronic systems or the integration of peripherals and accessories, we meticulously orchestrate every step to deliver a finished product that meets the highest standards of quality and performance. With our expertise in box building and final assembly, we offer unparalleled convenience and efficiency, streamlining the manufacturing process and expediting time-to-market for our clients.

Quality Assurance and Testing: Quality is at the forefront of our operations, and every assembled PCB undergoes rigorous testing to validate its functionality and performance. From automated testing procedures to manual inspections, we leave no stone unturned in ensuring that each product meets the highest standards of excellence. Our comprehensive testing protocols encompass functionality tests, electrical tests, and environmental stress tests, guaranteeing reliability in diverse operating conditions.

Packaging and Logistics: With the assembly process complete, the finished products are carefully packaged to safeguard against transit damage. Our packaging experts utilize industry-standard materials and techniques to ensure secure transportation, minimizing the risk of product mishandling. Leveraging strategic partnerships with reputable logistics providers, we facilitate seamless transportation and timely delivery to our client’s doorstep, regardless of geographical location.

Conclusion: In conclusion, executing customer orders for PCB assembly requires a harmonious blend of expertise, precision, and dedication. At our facility, we take pride in our ability to seamlessly orchestrate the production process, from initial consultation to final delivery. By prioritizing quality, efficiency, and client satisfaction, we strive to exceed expectations and establish ourselves as the partner of choice in the electronics manufacturing industry.

Through the integration of advanced technologies, stringent quality control measures, and unwavering commitment to excellence, we ensure that every customer order is executed with the utmost care and precision. As we continue to innovate and adapt to evolving market demands, our goal remains unchanged: to deliver superior results that drive success for our clients and propel our industry forward.