In the fast-paced world of electronic manufacturing, ensuring quality and efficiency is paramount. Among the arsenal of quality control measures, First Article Inspection (FAI) stands out as a crucial step, particularly in the intricate process of printed circuit board (PCB) assembly. Let’s delve into why FAI is indispensable in electronic manufacturing and PCB assembly processes.

Understanding First Article Inspection (FAI)

First things first, what exactly is FAI? In simple terms, FAI is a comprehensive examination and validation process carried out on the first manufactured part or assembly to verify compliance with the specified requirements. It involves meticulous scrutiny of every aspect of the product against the engineering drawings, specifications, and other applicable standards.

The Significance of FAI in PCB Assembly

Now, let’s zoom in on PCB assembly. In this intricate process, where countless components come together to form the backbone of electronic devices, precision is non-negotiable. Here’s why FAI holds immense importance:

- Identifying Potential Issues Early: FAI allows manufacturers to catch any discrepancies or defects in the early stages of production. This proactive approach prevents the escalation of issues, saving both time and resources in the long run.

- Ensuring Compliance: With constantly evolving standards and specifications in electronic manufacturing, FAI ensures that the assembled PCBs adhere to the required criteria. Whether it’s dimensional accuracy, component placement, or soldering quality, FAI leaves no stone unturned in ensuring compliance.

- Mitigating Risks: Electronic devices often serve critical functions in various industries, from healthcare to aerospace. Any malfunction or failure due to manufacturing defects can have severe consequences. FAI acts as a robust risk mitigation strategy by verifying the integrity and functionality of the assembled PCBs before mass production.

- Enhancing Customer Satisfaction: Quality is the cornerstone of customer satisfaction. By conducting FAI, manufacturers demonstrate their commitment to delivering flawless products, thereby fostering trust and loyalty among their clientele.

Implementing FAI in Electronic Manufacturing

Incorporating FAI into the electronic manufacturing workflow requires careful planning and execution. Here are some key steps involved:

- Detailed Planning: Prioritize FAI as an integral part of the manufacturing process right from the planning stage. Allocate resources, define inspection criteria, and establish clear protocols for conducting FAI.

- Thorough Documentation: Document every aspect of the FAI process, including inspection results, deviations, corrective actions, and approvals. This comprehensive documentation serves as a valuable reference for future productions and quality audits.

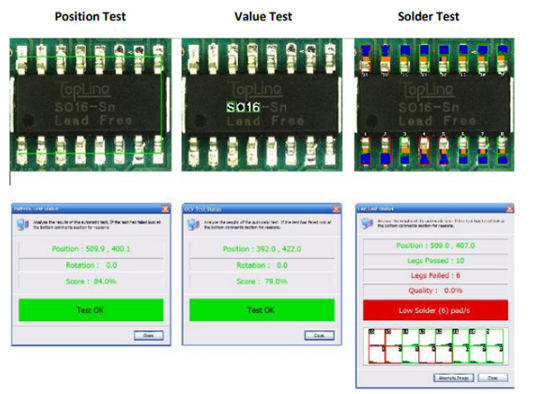

- Utilization of Advanced Technologies: Leverage cutting-edge technologies such as automated optical inspection (AOI) systems and 3D scanning to enhance the efficiency and accuracy of FAI. These tools not only streamline the inspection process but also detect minute defects that might escape manual scrutiny.

- Continuous Improvement: FAI shouldn’t be a one-time affair. Incorporate feedback from FAI results into the continuous improvement loop of the manufacturing process. Identify recurring issues and implement corrective measures to enhance overall quality and efficiency.

Conclusion

In the dynamic realm of electronic manufacturing, where precision and quality reign supreme, First Article Inspection emerges as a cornerstone practice. Particularly in PCB assembly, FAI plays a pivotal role in ensuring compliance, mitigating risks, and ultimately delivering superior products that meet the highest standards. By embracing FAI as a proactive quality assurance measure, manufacturers can not only safeguard their reputation but also elevate customer satisfaction in an increasingly competitive market landscape.

By prioritizing FAI in electronic manufacturing processes, companies can uphold their commitment to excellence and pave the way for continued innovation and advancement in the ever-evolving realm of technology.