PCBA testing, an essential part of the electronics manufacturing process, plays a pivotal role in ensuring product quality and performance. In this comprehensive guide, we delve into the significance of PCBA testing, its various testing methods, and how they are integrated into the production workflow.

Introduction

In the era of ubiquitous electronic devices, PCBA testing has emerged as a critical step in the manufacturing process. PCBA, short for Printed Circuit Board Assembly, is a fundamental component of electronic products. PCBA testing encompasses a range of methods aimed at verifying the functionality and integrity of these assemblies. Let’s explore how PCBA testing contributes to the quality assurance process.

Significance of PCBA Testing

PCBA testing is indispensable for ensuring that electronic products meet stringent quality standards. With consumers demanding increasingly sophisticated devices, manufacturers face pressure to deliver flawless products. PCBA testing acts as a safeguard against defects and malfunctions, ultimately enhancing customer satisfaction and brand reputation.

Various Testing Methods

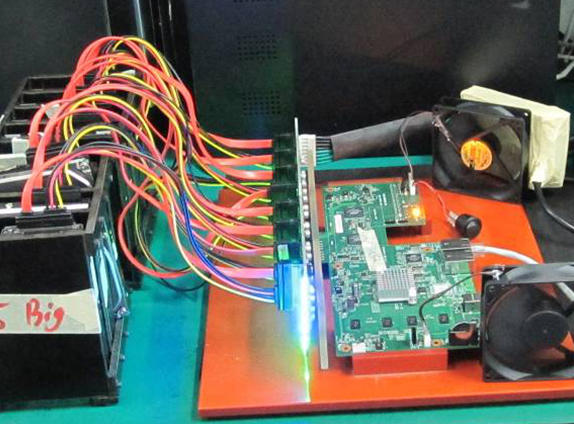

- Functional Testing:

- Functional testing is a cornerstone of PCBA testing, aimed at verifying whether the assembly performs as intended.

- By simulating real-world scenarios, functional testing evaluates the PCBA’s performance across different usage scenarios, ensuring optimal functionality.

- Carried in the end of PCB Assembly

- Electrical Testing:

- Electrical testing focuses on validating the integrity of electrical connections within the PCBA.

- This testing method detects shorts, opens, or incorrect connections, ensuring the assembly meets electrical specifications.

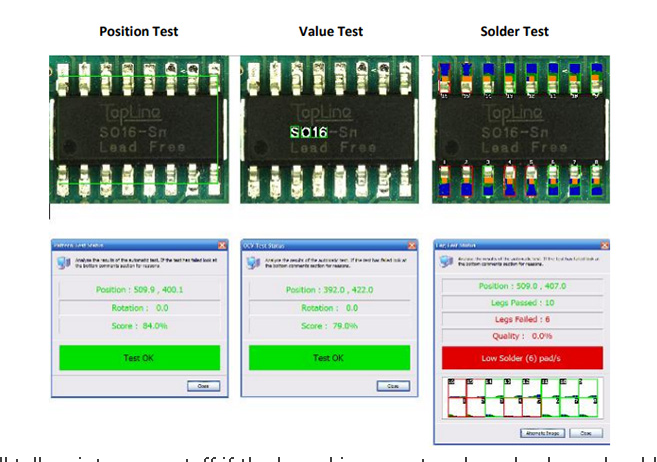

- Automated Optical Inspection (AOI):

- AOI technology automates the inspection process by capturing and analyzing images of the PCBA’s surface.

- By identifying discrepancies in component placement and solder joints, AOI enhances testing efficiency and accuracy.

- Visual Inspection:

- Visual inspection involves examining the PCBA’s surface for defects such as soldering quality and component placement accuracy.

- It complements other testing methods by identifying visible defects that may impact performance.

- Depending on the project, this may be repeated several times during the production process, and the manufacturer will arrange visual inspections at key points, especially during the production of the first sample.

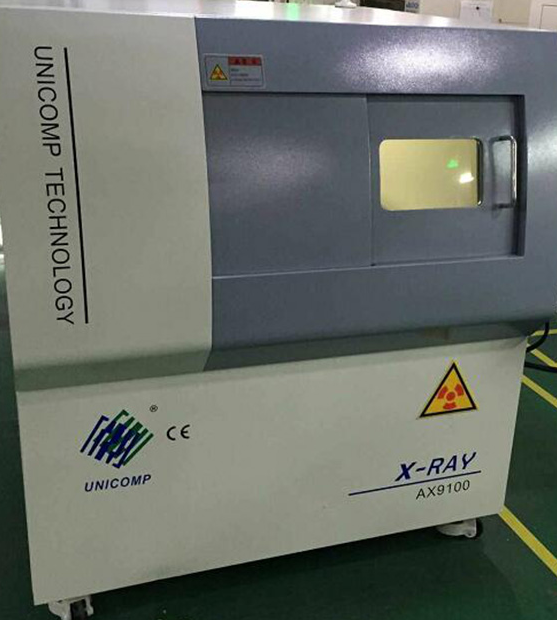

- X-Ray Inspection:

- X-ray inspection, also known as X-ray testing, provides insights into the internal structure of the PCBA.

- This non-destructive testing method detects defects such as solder voids, misalignments, and component anomalies, ensuring the integrity of complex assemblies.

Integration into the Production Workflow

PCBA testing is seamlessly integrated into the manufacturing workflow, spanning multiple stages of production. From initial component assembly to final inspection, each phase incorporates specific testing methods tailored to detect defects and ensure product quality.

Conclusion

In conclusion, PCBA testing is a vital aspect of electronics manufacturing, ensuring the reliability and performance of electronic products. By leveraging advanced testing methods such as AOI and X-ray inspection, manufacturers can detect and rectify defects early in the production process, minimizing rework and enhancing productivity. As technology advances, PCBA testing will continue to evolve, driving innovation and excellence in the electronics industry.