In China, the ranking of the top 6 water pump control module PCB assembly customization factories is for reference only because it involves a comprehensive evaluation of multiple factors, such as technical strength, production scale, product quality, customer reputation, etc.

However, according to relevant information about the water pump control module PCBA (PCB assembly) industry, the following are some factories with high visibility and influence in the industry:

1.Shenzhen Fumax Technology Co., Ltd

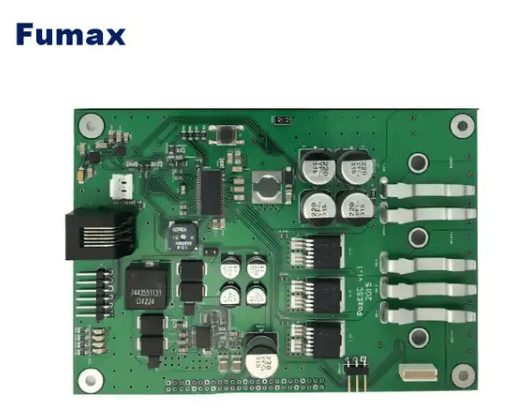

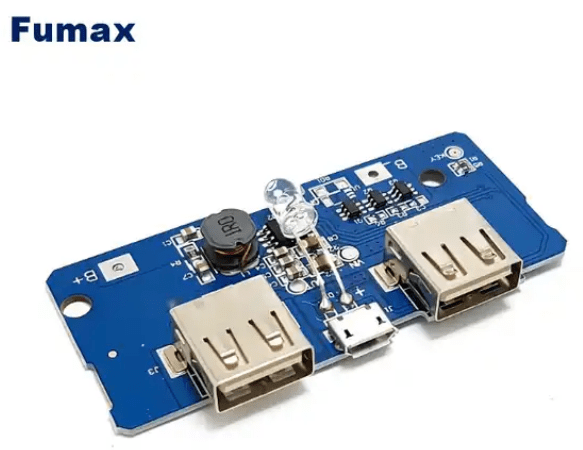

Fumax is a water pump PCB assembly service manufacturer in China. We are a company specializing in the production and processing of various PCBA solution development products, and have a complete and scientific quality management system.

The main products include PCBA customization, PCB assembly, PCB design layout, circuit board development, water pump SMT patch processing, water pump PCB test assembly, embedded software design, embedded hardware development, electronic components, microcontroller development boards, and circuit board circuits. Board, solar charger PCB assembly, inverter PCBA customization, water pump pressure automatic control switch module PCBA, air pump control module PCB OEM service.

It is an electronic manufacturing and processing factory integrating R&D, design, production and processing, and sales services. The PCB and PCBA factory is located in Fuyong, Shenzhen, China.

Date of establishment: 2007

Company address: Huafeng Science and Technology Park, Fengtang Avenue, Tangwei Community, Fuhai Street, Baoan District, Shenzhen City, Yihai Building, Nanshan District, Shenzhen City.

2.Hangzhou Ruisheng Electric Co., Ltd.

This is a high-tech enterprise focusing on the field of industrial automation. The water pump control module PCBA it produces has a good reputation in the industry.

Hangzhou Ruisheng Electric Co., Ltd. provides PCBA customization services for water pump control modules. They have a professional R&D team and advanced production equipment, and can customize production according to customer needs.

It has provided PCBA customization services to many companies, including some well-known companies. Their customer feedback has been good and speak highly of the quality and performance of their products.

Date of establishment: 2004

Company address: Building 9, High-tech Software Park, No. 1, Weiye Road, Binjiang District, Hangzhou City, Zhejiang Province.

- Shanghai Anchuan Electronic Technology Co., Ltd.: This is a high-tech enterprise specializing in the development and production of industrial automation control systems. Its water pump control module PCBA has a high degree of recognition in the market.

Date of establishment: 2007

Company address: No. 8, Huadan Road, Huaxin Town, Qingpu District, Shanghai. - Shenzhen Hexin Automation Technology Co., Ltd.: This is a high-tech enterprise engaged in the research and development, production and sales of industrial automation products. Its water pump control module PCBA has a good reputation in the industry.

Date of establishment: 2003

Company address: Building A, Building 6, Shenzhen International Innovation Valley, Dashi 1st Road, Xili Community, Xili Street, Nanshan District, Shenzhen. - Nanjing Yoube Electric Co., Ltd.: This is a high-tech enterprise focusing on the field of industrial automation. Its water pump control module PCBA has a high reputation in the industry.

Date of establishment: 2002

Company address: No. 126, Tianyuan Middle Road, Jiangning District, Nanjing City. - Wuxi Zhongwei Aixin Electronics Co., Ltd.: This is a company specializing in the design and production of integrated circuits. Its water pump control module PCBA has a certain market share in the industry.

Date of establishment: 1998

Company address: Wuxi City, Jiangxi Province.

The above information is for reference only, because the technical strength, production scale, product quality, customer reputation, etc. of each factory are different, so you need to understand the situation of each factory in detail before making a choice.