How does the top water pump PCB assembly manufacturer in China conduct production and manufacturing? Next, Fumax will explain in detail the process and required equipment of PCB industrial assembly.

What are the steps to assemble the water pump control board PCB?

PCB assembly of the water pump control board includes the following steps:

- Prepare materials: water pump control board PCB, electronic components, solder, flux, tweezers, screwdrivers, wires, etc.

- Determine the layout: Arrange the electronic components according to their positions on the water pump control board PCB, being careful not to cover each other or short circuit.

- Welding: Use solder and flux to weld the electronic components to the water pump control board PCB to ensure the welding is firm.

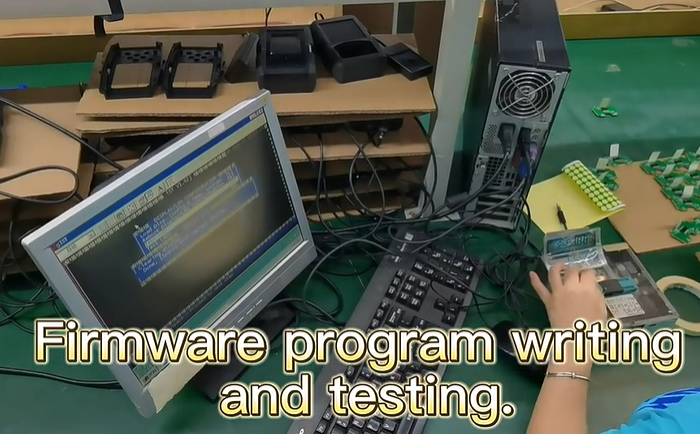

- Debugging: After completing the welding, conduct debugging to check whether it can work normally.

- Assembly: Assemble the water pump control board PCB and other components (such as water pumps, sensors, etc.) to ensure that the connections are firm.

- Test: After completing the assembly, perform a test to check whether it can work properly.

It should be noted that when performing PCB assembly, relevant regulations and standards must be followed to ensure quality and safety. At the same time, be careful during operation to avoid damaging electronic components or the water pump control board PCB.

What materials are used for water pump control board PCB assembly?

The materials used for water pump control board PCB assembly include the following categories:

- Substrate: Usually organic resin copper-clad laminate is used as the substrate.

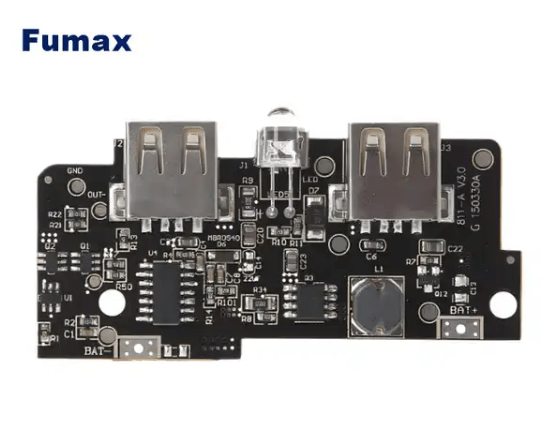

- Electronic components: including resistors, capacitors, diodes, transistors, relays, etc.

- Solder and flux: used to solder electronic components to PCB.

- Tweezers, screwdrivers and other tools: used for assembly and debugging.

- Wires and connectors: used to connect the water pump control board PCB and other components.

These materials play an important role in the assembly process, and choosing the right materials and tools can ensure the quality and efficiency of the assembly.

Water pump control board PCB assembly usually requires the following tools:

- Soldering station: used to solder electronic components to PCB.

- Solder and flux: used for soldering electronic components.

- Tweezers: used to pick up electronic components and wires.

- Screwdriver: used for tightening screws and debugging.

- Test instrument: used to test the function and performance of the circuit.

These tools can be selected from different types and brands according to actual needs, but the quality and precision of the tools must be guaranteed to ensure the quality and efficiency of assembly.

Tools required for industrial manufacturing water pump control board PCB assembly

Industrial manufacturing water pump control board PCB assembly usually requires the following tools:

- Automatic stencil printing machine: used to print solder paste evenly onto the PCB board.

- Solder paste printer: used to print solder paste onto PCB boards.

- High-speed placement machine: used to accurately mount electronic components onto PCB boards.

- Wave soldering machine and reflow soldering machine: used to solder electronic components to PCB boards.

- Testing equipment: used to test the quality and performance of PCB boards.

These tools are essential in industrial manufacturing and can greatly improve production efficiency and product quality. At the same time, in order to ensure the quality and accuracy of the tools, regular maintenance and calibration are usually required.

How to improve PCB board production efficiency and product quality through tools?

By using the right tools and techniques, PCB board production efficiency and product quality can be significantly improved. Here are some ways:

- The use of automated production tools: such as automatic assembly lines, SMT placement machines, AOI optical inspection and other equipment can greatly reduce workers’ labor and improve production efficiency and quality.

- Optimize PCB board design: adopt modular design, reasonable layering, standardized naming and other measures to improve design efficiency and accuracy. At the same time, the use of shortcut keys and automated tools of design software, such as quick routing, design specification checking, etc., can also improve design efficiency.

- Use high-precision manufacturing equipment: such as high-precision drilling machines, cutting machines and other equipment to ensure the accuracy and quality of PCB boards.

- Introduction of MES system: MES system can monitor the production process in real time, provide accurate production data, help enterprises optimize production plans and resource allocation, and improve production efficiency.

- Use quality testing equipment: such as X-ray inspection machines, ultrasonic welding machines and other equipment, which can promptly detect and solve quality problems during the production process to ensure product stability and reliability.

- Strengthen employee training and technical support: Operators need to be familiar with various equipment and technologies and be able to solve problems that arise during the production process in a timely manner. Therefore, companies need to strengthen employee training and technical support and improve the skill level of operators.

In summary, by using appropriate tools and technologies, PCB board production efficiency and product quality can be improved, costs and risks can be reduced, and sustainable development can be achieved.