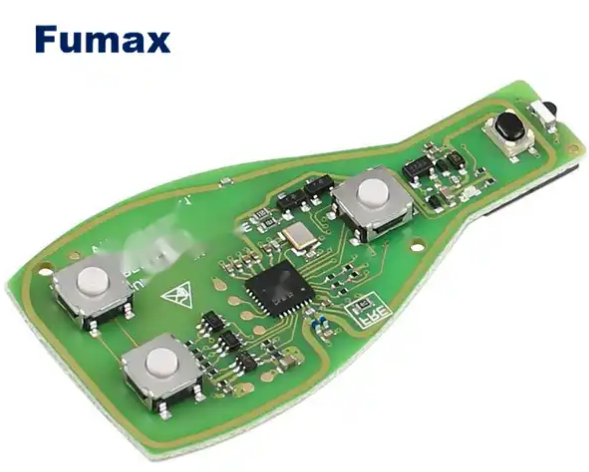

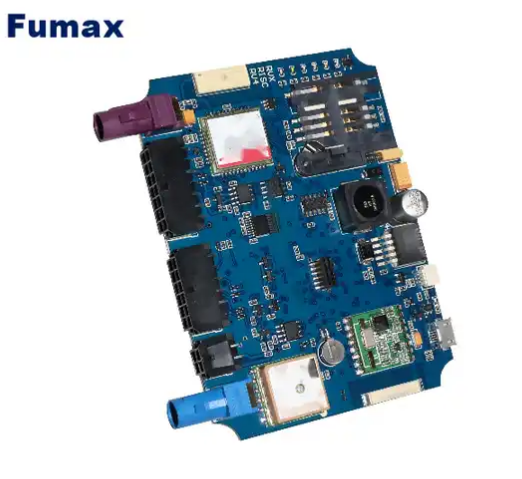

Fumax provides various PCB board circuit layout design, PCB assembly, PCB customization, SMT chip processing and other services.

What is the high temperature resistance of the temperature and humidity sensor PCB substrate?

The high temperature resistance of the temperature and humidity sensor PCB substrate mainly depends on its manufacturing materials and manufacturing process. Normally, temperature and humidity sensor PCB substrates use copper-clad laminates such as FR-4 or CEM-1. These materials have good high temperature resistance and can withstand higher temperatures.

During the production process, the PCB substrate needs to be baked to eliminate internal stress and improve its high temperature resistance. In addition, the surface treatment of the PCB substrate will also affect its high temperature resistance.

For example, the use of surface treatment processes such as hot air leveling (HASL) or organic coating (OSP) can further improve the high temperature resistance of the PCB substrate.

In general, the temperature and humidity sensor PCB substrate has good high temperature resistance and can meet the working needs of the temperature and humidity sensor.

Is the PCB design of the temperature and humidity control board a multi-layer board?

The PCB design of the temperature and humidity control board can be a multi-layer board or a single-layer board. This depends on the specific design requirements and manufacturing process.

The advantage of multilayer boards is that they provide better electrical performance and signal integrity while better protecting internal circuits and components. In addition, multilayer boards can provide better heat dissipation performance and mechanical strength. However, the manufacturing cost of multi-layer boards is also relatively high and requires more complex manufacturing processes and technologies.

The advantages of single-layer boards are lower manufacturing costs and easy manufacturing and maintenance. However, single-layer boards have relatively poor electrical performance and signal integrity, and also require more space to accommodate components and circuits.

In the PCB design of the temperature and humidity control board, you can choose to use a multi-layer board or a single-layer board according to actual needs. If you need better electrical performance, signal integrity, and mechanical strength, you can choose a multilayer board; if you need lower manufacturing costs and a simpler manufacturing process, you can choose a single-layer board.

Who are the top 5 temperature and humidity control board PCB manufacturers?

- Shenzhen Fumax Technology Co., Ltd.

Fumax specializes in one-stop services such as PCB design and PCB assembly customization.

The company has a team of senior engineers with more than ten years of work experience, and has more than a dozen single-chip microcomputer and PCB board R&D designers and single-chip microcomputer development, home appliance control board development, electronic product development, temperature and humidity control PCB assembly, motor control, heating and cooling control , intelligent control and other technical talents.

The company’s production equipment includes high-precision imported equipment, fully automatic solder paste printing machines, SPI, multiple high- and medium-speed placement machines, 10 temperature zone reflow soldering, wave soldering, selective wave soldering, X-Ray testing, AOI equipment, and automatic soldering. Machine and so on.

The PCBA factory is located in Shenzhen, China. It has provided electronic design and manufacturing services to global customers for many years; it is a leading brand in China’s EMS electronics foundry industry.

fumax is a professional PCB manufacturer that has won the trust and praise of customers with its high-quality products and services. If you need PCB manufacturing services, you can contact fumax company to learn more about the company and PCB products. - Shenzhen Xintai Micro Technology Co., Ltd.

Shenzhen Xintai Micro Technology Co., Ltd. is a professional PCB manufacturer dedicated to providing customers with high-quality, high-reliability PCB products and services. The company has advanced production equipment and technology and can provide multi-layer boards, high-precision, and high-density PCB manufacturing services. It can also provide customized PCB solutions according to customer needs.

In terms of PCB manufacturing, Xintai Micro Technology has a complete quality control system and production process, and has strict quality control from raw material procurement to production, processing, testing and other links. The company has a professional technical team that can provide customers with professional technical support and after-sales service. - Xinyingchuang Electronic Technology Co., Ltd.

Xinyingchuang Electronic Technology Co., Ltd. is a professional PCB manufacturer dedicated to providing customers with high-quality, high-reliability PCB products and services. The company has advanced production equipment and technology and can provide multi-layer boards, high-precision, and high-density PCB manufacturing services. It can also provide customized PCB solutions according to customer needs. - Shenzhen Jieke Circuit Co., Ltd.

Shenzhen Jieke Circuit Co., Ltd. is a company specializing in the sales of PCB boards and circuit boards, providing domestic trade and import and export of goods and technology services.

The main products of Jieke Circuit Company include PCB boards, circuit boards, high-frequency boards, aluminum substrates, FR-4 fiberglass boards, etc., which are widely used in communications, industrial control, automotive electronics and other fields.

Jieke Circuit Company has a professional technical team to provide customers with a series of services such as PCB design, manufacturing, and placement. At the same time, the company also provides customized PCB solutions to meet the different needs of customers.

- Nanjing Haichuan Electronics Co., Ltd.

Nanjing Haichuan Electronics Co., Ltd. is a manufacturer specializing in temperature control protectors such as automotive motor protectors, overcurrent protectors, thermal protectors, wiper motor protectors, and window motor protectors. It has complete and scientific quality management system.

The PCBs of Nanjing Haichuan Electronics Co., Ltd. mainly involve automotive motor protectors, overcurrent protectors, thermal protectors and other related products. These products are widely used in glass lift motors, wiper motors, sunroof motors, car water tanks, car heaters, white goods and other fields.

Nanjing Haichuan Electronics Co., Ltd. has advanced production equipment and technology, established a complete automated production line, and is committed to the research, development and manufacturing of high-reliability protectors in the automotive field. Its PCB products feature high quality, high reliability, and high precision, and comply with relevant standards and customer requirements.

When Nanjing Haichuan Electronics Co., Ltd. performs PCB assembly, it mainly takes the following steps:

- Raw material preparation: Purchase corresponding electronic components, PCB boards and other raw materials as needed.

- Solder paste printing: Print solder paste on the PCB board to connect the components to the PCB board during the subsequent welding process.

- Component mounting: Mount electronic components onto the PCB board.

- Welding: Connect the components to the PCB board through welding.

- Inspection: Inspect the welded PCB board to ensure that there are no soldering problems, short circuits, etc.

- Aging test: Conduct aging test on the welded PCB board to ensure the stability and reliability of the product.

- Packaging: Products that pass the aging test are packaged for delivery to customers.

During the PCB assembly process, Nanjing Haichuan Electronics Co., Ltd. introduced automated production lines to improve production efficiency and quality. At the same time, the company also focuses on quality control and environmental management to ensure that products meet relevant standards and customer requirements.

To learn more, please follow us. If you need electronic design, electronic product assembly, WiFi module PCB design, motor controller PCB assembly, smart home electronic control board assembly services, please contact us.