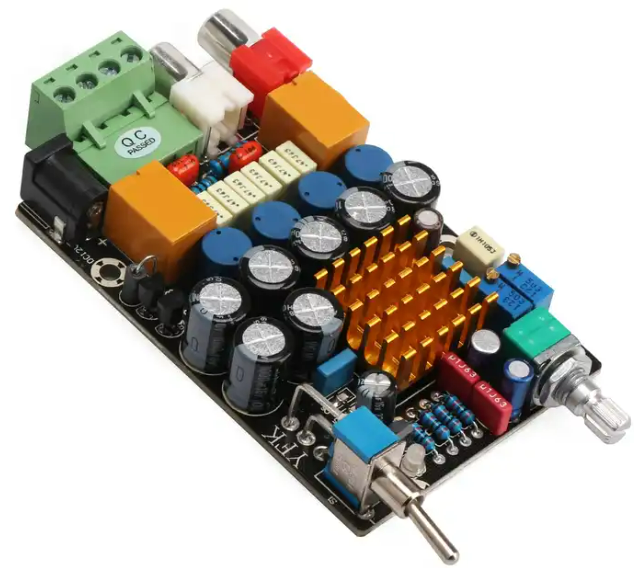

Electronic contract manufacturing company PCB customization one-stop service company

The electronic contract manufacturing company provides one-stop PCB customization services, including design, manufacturing, testing and other links. It is committed to meeting customer needs and providing high-quality and efficient services.

- Electronic contract manufacturing company PCB customization one-stop service company

- What is an electronics contract manufacturing company?

- What issues should you pay attention to when working with a PCB custom electronics contract manufacturing company?

- Electronic contract manufacturing company, PCB customization one-stop service company list

What is an electronics contract manufacturing company?

Electronic Manufacturing Services (EMS) is a company specializing in electronic contract services. They are committed to providing efficient, safe and convenient electronic contract solutions to help enterprises and individuals achieve digital contract management, improve contract signing efficiency and reduce contract risks.

EMS companies usually have the following characteristics:

Provide an electronic contract platform

EMS companies will develop or use an advanced electronic contract platform, which is highly secure and uses data encryption technology and identity verification systems to ensure the privacy and security of user information. At the same time, the platform has a complete authority management system. Only authorized users can access the contract content and perform signing operations to avoid the risk of information leakage and illegal tampering.

User-friendliness

The platforms provided by EMS companies usually have good ease of use and convenience. Users can access the platform through terminal devices such as mobile phones and computers. There is no need to install cumbersome software. They can sign contracts and manage operations simply through the web page. The platform provides an intuitive and friendly interface design and operation guidance, allowing users to get started quickly and easily complete the contract signing process.

Feature-rich

The platforms provided by EMS companies are usually feature-rich. Users can complete a variety of contract operations through the platform, including creating contracts, editing contracts, signing contracts, archiving contracts, etc. In addition, it also provides contract template library, contract approval process management, contract query and statistics functions to help users manage the entire contract life cycle and improve the efficiency and accuracy of contract processing.

Integration

The platform provided by EMS companies is highly integrated with other business systems. Supports integration with corporate financial systems, human resources systems, etc. to realize automatic transmission and sharing of information. In this way, users can easily obtain relevant business data while signing contracts, improving business efficiency and accuracy.

Professional service team

EMS companies usually have professional and dedicated service teams to provide users with timely and thoughtful technical support and solutions. Whether users encounter problems during use or have contract management needs, we can provide users with quick responses and solutions.

In short, electronic contract manufacturing companies are companies that specialize in electronic contract services. They use advanced technology and professional service teams to help companies and individuals achieve digital contract management, improve contract signing efficiency, and reduce contract risks.

What issues should you pay attention to when working with a PCB custom electronics contract manufacturing company?

When working with a PCB custom electronics contract manufacturing company, you need to pay attention to the following issues:

- Supplier selection: This is the first step in establishing a long-term cooperative relationship. When selecting a supplier, you need to consider its credibility and qualifications, production capacity, service level, etc. Make sure that the selected supplier can guarantee the stability of product quality and delivery time, high production efficiency, advanced equipment, good service attitude and quick response.

- Proofing work: In critical equipment manufacturing work with high technical investment, such as circuit board production, the proofing process is crucial. The preliminary proofing work should be done together with the manufacturer, and the actual product presentation effect and key indicators of the sample should be tested and confirmed to ensure the rights and interests of the demander and the circuit board manufacturer.

- Specifications and design: The specifications and design requirements of the PCB need to be clarified. Different application scenarios may require different PCB specifications and designs. Therefore, before cooperation begins, it is necessary to clarify your application scenarios and needs to ensure that the PCB customization company can design and manufacture according to your needs.

- Manufacturing process: You need to understand the manufacturing process and processes of the PCB customization company. Different manufacturing processes and processes may affect product quality and delivery time. Therefore, before starting cooperation, you need to clearly communicate with the PCB customization company about its manufacturing process and process to ensure that it can meet your needs.

- Quality control: It is necessary to ensure that the PCB customization company has good quality control measures during the production process. The quality of PCB is directly related to the quality and performance of the entire product. Therefore, it is necessary to negotiate with the PCB customization company and clarify the quality control requirements, including inspection standards, inspection methods, etc.

- Delivery time: It is necessary to clarify the delivery time commitment of the PCB customization company. Before starting cooperation, you need to confirm with the PCB customization company its ability to deliver on time, and clarify the delivery time, delivery conditions, etc.

- Price and payment method: A reasonable price and payment method need to be negotiated with the PCB customization company. The price should take into account factors such as product quality, delivery time, service, etc. The payment method should take into account the rights and risk control of both parties.

- Contract terms: You need to carefully read and understand the contract terms. The contract terms should clarify the rights and obligations of both parties, including product quality, delivery time, payment method, liability for breach of contract, etc. If you have any questions or uncertainties, you should promptly negotiate with the PCB customization company and modify the contract terms.

- Communication and after-sales service: It is necessary to maintain good communication and after-sales service with the PCB customization company. During the cooperation process, if you encounter any problems or questions, you should contact the PCB customization company in time and communicate to solve them. After-sales service should include repair, maintenance, replacement and other measures to ensure the long-term use and life of the product.

In short, working with a PCB custom electronics contract manufacturing company requires careful consideration of many aspects to ensure that the cooperation goes smoothly and achieves the desired results.

Electronic contract manufacturing company, PCB customization one-stop service company list

Fumax recommends electronic contract manufacturing companies and PCB customization one-stop service companies to you. Here are some recommendations:

- Shenzhen Fumax Technology Co., Ltd. is an electronic contract manufacturing company specializing in high-quality, sample-to-bulk production, quick response to new product introductions (NPI), rich product experience, and one-stop service. Specifically, Fumax Technology provides services such as design, material procurement, circuit board patch assembly, housing (plastic & metal) production, complete product assembly and transportation.

Committed to providing customers with first-class electronic manufacturing services.

In short, Fumax Technology has rich experience and professional technical strength in the field of electronic manufacturing, and can provide customers with a full range of customized services. - Chongda Technology: The company has a professional PCB design team and advanced production lines, providing a full range of services from design to production.

- Xingsen Express: This company provides PCB rapid prototyping and small batch customization services to meet the diverse needs of customers.

- Oscon Technology: This company focuses on PCB manufacturing and provides a full range of customized services.

- Shenghong Technology: This company has a professional PCB design team and advanced production lines, providing PCB customization services.

- Jingwang Electronics: This company provides PCB customization services, including the production of single-sided, double-sided and multi-layer boards.

The above companies are all professional one-stop service companies for PCB customization. They have rich experience and advanced production equipment and can meet the different needs of customers.