As the popularity of smartphones and the speed of upgrading continue to accelerate, smartphone motherboard PCB assembly customization services have become a popular business in the electronics industry. This article will introduce the relevant content of this service in detail.

Smartphone motherboard PCB overview

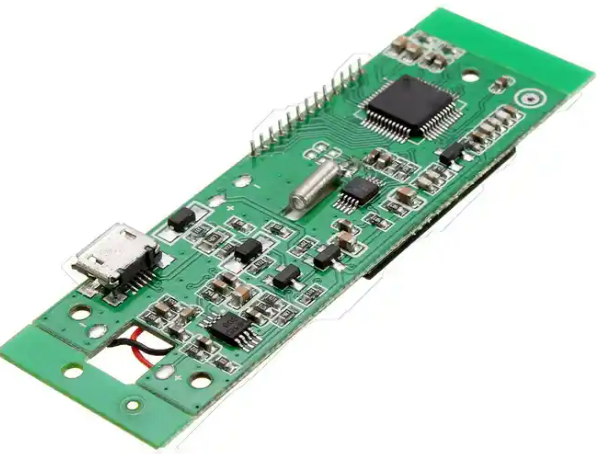

Smartphone motherboard PCB is the main component on the smartphone circuit board, which carries various functions and performance of the mobile phone. PCB is made of multiple layers of insulating materials bonded together and has the characteristics of high precision, high density and high reliability. On the PCB, various electronic components such as processors, memory, radio frequency chips, sensors, etc. are welded on the circuit board, and information transmission and data processing are realized through circuit connections on the PCB.

Smartphone motherboard PCB assembly customization service

Smartphone motherboard PCB assembly customization service refers to the design and production of PCB circuit boards that meet the customer’s specific needs based on the customer’s needs and specifications and requirements. The scope of this service is wide-ranging, including everything from design, manufacturing, assembly to testing.

PCB design service is the first step in the entire customization service, which involves the structural design, circuit design and component layout design of the circuit board. In this process, designers need to consider various factors, such as circuit performance, component arrangement, heat dissipation design, etc., to design the optimal PCB solution.

- PCB manufacturing services

PCB manufacturing service is one of the core links of the entire customized service, which includes PCB substrate production, diaphragm production, component mounting, welding, inspection and other steps. In this process, manufacturers need to use advanced production equipment and manufacturing processes to ensure the quality and performance of PCBs.

- PCB assembly services

PCB assembly service is the process of soldering electronic components to PCB circuit boards and completing related testing and inspection. In this process, it is necessary to ensure the welding quality and functionality of components to ensure the reliability and stability of the product.

- PCB testing services

PCB testing services are the testing and inspection of already assembled circuit boards to ensure they meet customer requirements and specifications. Test content includes electrical performance testing, functional testing, durability testing, etc.

Advantages of smartphone motherboard PCB assembly customization services

- Efficiency: This service can be customized according to customer needs, avoiding the cumbersome process of customers’ own research and development and production, saving time and costs.

- Professionalism: The service is provided by professional designers and manufacturers who have rich experience and skills to provide customers with high-quality products and services.

- Reliability: This service strictly follows industry standards and specifications and uses advanced production equipment and manufacturing processes to ensure product quality and performance.

- Flexibility: The service can be flexibly adjusted according to customer needs and meet customers’ changing needs at any time.

- Economical: The price of this service is reasonable, and compared with the cost of self-development and production, it has a high cost performance.

Smartphone motherboard PCB assembly customization service process

- Customer demand analysis: Analyze and understand the specific needs of customers, including product specifications, performance, budget, etc.

- Solution design: Design a PCB solution that meets the customer’s needs, including circuit board structural design, circuit design and component layout design, etc.

- Quotation and contract signing: Give a quotation based on the design plan, sign a contract with the customer and confirm the payment method.

- Manufacturing and testing: Carry out PCB manufacturing, testing and functional testing according to the design plan.

- Delivery and acceptance: Deliver the product to the customer and assist the customer in acceptance to ensure that the product meets customer needs.

- Technical support and after-sales service: Provide customers with necessary technical support and after-sales service to ensure smooth use.

Summarize

Smartphone motherboard PCB assembly customization service is an efficient, professional, reliable and economical solution that can help customers quickly achieve their smartphone R&D and production goals. This service is provided by professional designers and manufacturers, strictly follows industry standards and specifications, and uses advanced production equipment and manufacturing processes to ensure product quality and performance.

At the same time, the price of this service is reasonable and has a high cost performance compared with the cost of self-development and production. In addition, this service can also provide customers with flexible support and professional technical support and after-sales service teams to solve problems arising in the project and promptly meet customers’ changing needs to provide customers with high-quality products and services.

Fumax smartphone motherboard PCB customization factory

Smartphone motherboard PCB customization companies are committed to providing customers with efficient and high-quality customization services. Smartphone motherboard PCB customization factory is a factory specializing in mobile phone motherboard and PCB board customization services. They meet customer needs in all aspects from design, manufacturing to testing.

The company has a professional technical team with deep industry experience and professional technical knowledge, capable of providing high-quality, high-reliability customized products. In addition, the company attaches great importance to customer experience and provides around-the-clock technical support and after-sales service to ensure customer satisfaction.

In terms of business, the company focuses on innovation and research and development, constantly optimizing production processes and improving product quality to adapt to changing market demands. At the same time, the company is also committed to environmental protection and sustainable development, using environmentally friendly materials and green production methods to contribute to society.