The prototype PCB LED board component assembly and customization factory focuses on providing customers with personalized, high-quality LED board component assembly and customization services.

We have a professional design team and advanced production equipment, able to customize designs according to customer needs to ensure product quality and delivery time. We are committed to providing customers with high-quality products and services to meet the application needs in different fields.

introduction

With the rapid development of science and technology, electronic components are used more and more widely in various fields. Among them, LED, as an important part of modern electronic equipment, is widely used in lighting, display, indication and other fields.

In order to meet the needs of different customers, a custom assembly factory for prototype PCB LED board components came into being. This article will introduce in detail the operation model, production process, quality control and other aspects of the prototype PCB LED board component customization assembly factory.

Operating model

- Customer demand analysis

The first task of the prototype PCB LED board component custom assembly factory is to analyze the customer’s needs. Through an in-depth understanding of customer needs, including LED specifications, quantity, color, brightness, etc., we provide customers with personalized solutions.

- Customized design

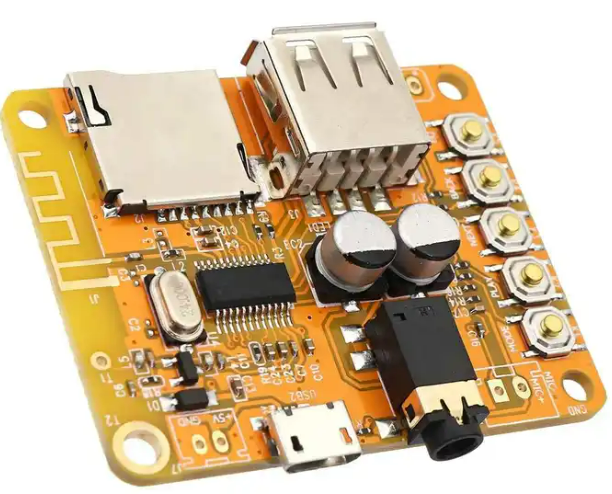

Based on customer needs, the design team of the custom assembly factory for prototype PCB LED board components will carry out customized designs. This includes circuit board design, LED layout, driver circuit design, etc. After the design is completed, it will be confirmed with the customer to ensure that the design solution meets the customer’s requirements.

- Production and processing

According to the design plan, the prototype PCB LED board components custom assembly factory will carry out production and processing. This includes PCB board production, LED welding, drive circuit assembly, etc. During the production process, the quality of every link will be strictly controlled to ensure the quality of the product.

- Quality inspection

After production is completed, the prototype PCB LED board component customization assembly factory will conduct strict quality inspection on the products. This includes testing of LED brightness, color, stability, etc. Only products that pass the test can leave the factory to ensure that we provide customers with high-quality products.

Production Process

- Raw material procurement

The prototype PCB LED board component customization assembly factory will purchase raw materials according to production needs, including PCB boards, LEDs, drive circuits, etc. When purchasing, we will choose high-quality suppliers to ensure the quality of raw materials.

- Production plan formulation

Based on customer needs and production capabilities, the prototype PCB LED board component customization assembly factory will develop a detailed production plan. This includes production time, personnel scheduling, equipment usage, etc. Ensure the production process is carried out in an orderly manner.

- Production and processing

According to the production plan, the prototype PCB LED board components custom assembly factory will carry out production and processing. This includes PCB board production, LED welding, drive circuit assembly, etc. During the production process, the process flow will be strictly followed to ensure product quality.

- Quality inspection and packaging

After production is completed, the prototype PCB LED board component custom assembly factory will conduct strict quality inspection on the products. Products that pass the inspection will be packaged and prepared for shipment. During the packaging process, attention will be paid to the protection of the product to ensure that the product is not damaged during transportation.

QC

- Raw material control

The prototype PCB LED board component custom assembly factory will conduct strict quality control on the raw materials. When purchasing, we will select high-quality suppliers to ensure that the quality of raw materials meets the requirements. At the same time, regular random inspections of raw materials will be carried out to ensure the stable quality of raw materials.

- Production process control

During the production process, the prototype PCB LED board component customization assembly factory will establish a strict production process and quality management system. By formulating detailed operating procedures and process flows, we ensure that every link meets quality requirements. At the same time, key links in the production process will be monitored and recorded to ensure traceability of product quality.

- Quality inspection and control

The prototype PCB LED board component customization assembly factory will conduct strict quality inspection on the products. The inspection content includes the brightness, color, stability and other aspects of the LED. Only products that pass the inspection can leave the factory to ensure that we provide customers with high-quality products. At the same time, inspection data will be recorded and analyzed to detect and solve quality problems in a timely manner.

Summary and Outlook

As an important part of the field of electronic components, the prototype PCB LED board component customization assembly factory provides customers with personalized solutions and high-quality products. During the operation process, product quality and customer satisfaction are improved through in-depth analysis of customer needs and strict control of production processes and quality.

Looking to the future, with the continuous development of technology and changing social needs, the prototype PCB LED board component customization assembly factory will continue to innovate and develop to provide customers with better products and services.