The selection of PCB substrate used in industrial control boards is an important issue because it directly affects the performance, reliability and cost of the entire control board.

When selecting PCB substrate, you need to consider a variety of factors, including application scenarios, environmental conditions, mechanical properties, electrical properties, cost, etc.

The following is a detailed analysis of PCB substrate selection for industrial control boards:

Application scenarios

Different application scenarios have different requirements for PCB substrate materials. For example, for industrial control boards that need to withstand greater stress, you need to choose a base material with higher mechanical strength; for applications that require high temperature resistance and corrosion resistance, you need to choose a base material with better heat resistance and corrosion resistance. . Therefore, when selecting PCB substrate, you need to consider the application scenarios and performance requirements of the product.

environmental conditions

Industrial control panels usually need to work in harsh environmental conditions, such as high temperature, high humidity, high corrosion, etc. Therefore, when selecting PCB substrate, you need to consider the environmental adaptability of the product. For example, for industrial control panels that need to work in high-temperature environments, you need to choose a substrate with better heat resistance; for industrial control panels that need to work in high-humidity environments, you need to choose a substrate with better moisture resistance.

Mechanical behavior

Mechanical properties are one of the important indicators of PCB substrate, including tensile strength, bending strength, impact strength, etc. Different substrates have different mechanical properties, so the mechanical performance requirements of the product need to be considered when selecting.

For example, for industrial control boards that need to withstand greater stress, you need to choose a base material with higher mechanical strength; for industrial control boards that need to have good fatigue resistance, you need to choose a base material with better fatigue resistance.

Electrical properties

Electrical properties are one of the important indicators of PCB substrate, including insulation resistance, dielectric constant, etc. Different substrates have different electrical properties, so the electrical performance requirements of the product need to be considered when selecting. For example, for industrial control boards that require high insulation performance, you need to choose a substrate with a lower dielectric constant; for industrial control boards that require good electrical breakdown resistance, you need to choose a substrate with better electrical breakdown resistance. material.

PCB substrate cost

Cost is one of the important considerations in selecting PCB substrate. The prices of different substrates vary greatly, so the cost and performance requirements of the product need to be considered when selecting. On the premise of ensuring performance, choosing a lower-cost substrate can reduce production costs and improve product competitiveness.

Common PCB substrates and their characteristics

- Paper substrate

Paper substrate is a traditional PCB substrate, mainly composed of paper fiber and organic adhesive. The advantages of paper substrates are low cost, light weight, recyclability, and suitable for low-cost, miniaturized electronic devices. However, paper substrates have poor mechanical properties and are easily affected by moisture and high temperatures, making them unsuitable for use in harsh environments.

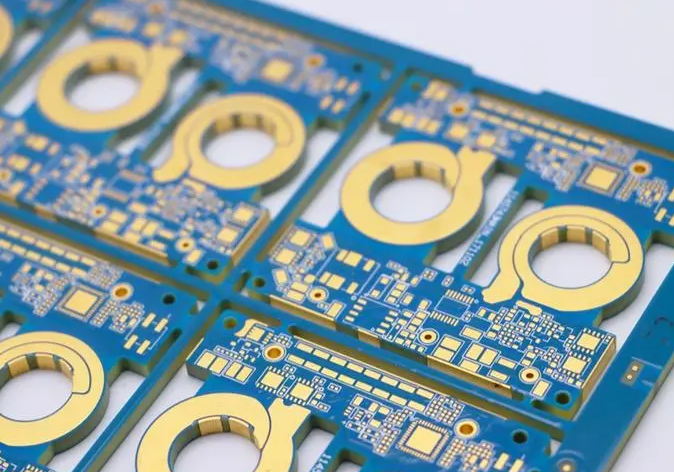

- Glass fiber reinforced panel

Fiberglass reinforced panel is a composite material composed of glass fiber and resin. This substrate has excellent mechanical properties, heat resistance and corrosion resistance, making it suitable for high-strength, high-durability electronic equipment. However, fiberglass reinforced panels are more expensive and difficult to process.

- Polytetrafluoroethylene (PTFE for short)

PTFE is a synthetic material with excellent electrical insulation properties, heat resistance and chemical resistance. The advantages of PTFE base material are high temperature resistance, corrosion resistance, and low friction coefficient. It is suitable for electronic equipment in high temperature, high humidity, and high corrosion environments. However, PTFE has a higher cost and is more difficult to process.

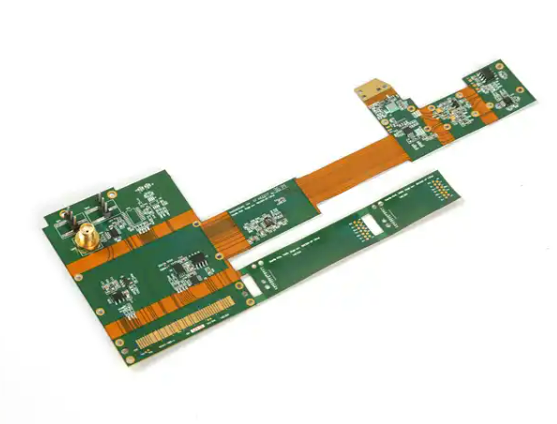

- Polyimide (PI for short)

Polyimide is a high-performance organic material with excellent high temperature resistance, corrosion resistance and electrical insulation properties. The advantages of PI substrate are high temperature resistance, corrosion resistance and low dielectric constant. It is suitable for electronic equipment in high temperature, high humidity and high corrosion environments. However, the cost of PI is high and processing is difficult.

Summary and suggestions

When selecting the PCB substrate for industrial control boards, comprehensive considerations need to be made based on factors such as product application scenarios, environmental conditions, mechanical properties, electrical properties, and cost.

On the premise of ensuring performance, choosing a lower-cost substrate can reduce production costs and improve product competitiveness. At the same time, with the continuous advancement and innovation of science and technology, new substrates and manufacturing technologies are also emerging, providing more choices and development space for PCB board manufacturing.

Therefore, it is recommended that enterprises keep paying attention to industry trends and technological developments, and actively introduce and apply new technologies and materials to improve product performance and competitiveness.