The charges of China’s PCB board processing plant varies from various factors. The following are some factors and detailed introductions that affect charges:

- Board type and thickness: Different plate types and thickness have a significant impact on the price. Common types of board include FR4, CEM-1, aluminum substrates, etc., and the thickness range is usually between 0.2mm and 3.2mm. Generally speaking, the use of more expensive materials and thinner plates will increase the price.

- Process requirements: There are many types of processing processes of PCB boards, including gold plating, Shenyin, Shenxi, etc. Different process requirements will also affect the price. In addition, if you need to add special processes such as welding layers, silk prints, and golden fingers, it will also increase costs.

- Size and version of the version: The size and version of the PCB board will affect the complexity of the processing and the amount of materials. Generally speaking, the larger the size, the more complicated the method of fighting, the higher the price.

- Quantity and delivery time: Generally speaking, the more quantity, the shorter the delivery time, and the more advantageous the price. Therefore, batch production and rapid delivery can reduce unit costs.

- Special requirements: If there are special requirements such as shockproof and waterproof, special structures and materials need to be used, which will lead to increased costs.

- Equipment and automation: High -precision equipment and automated production can improve production efficiency and product quality, but also increase the initial investment cost.

- Geographical location and logistics costs: The geographical location and logistics cost of the processing plant will also affect the quotation. If the customer is far from the processing plant, the logistics cost may increase.

- Artificial cost: With the development of the economy and the changes in the population structure, China’s labor costs are also rising. Therefore, the labor cost of the processing plant is also one of the important factors affecting the quotation.

- Market competition: The competition in the PCB board processing industry is relatively fierce, and the market price is affected by competition. In order to obtain orders, some processing factories may adopt a price reduction strategy.

- Brand and quality: Well -known brands and quality assurance may increase the price accordingly. Customers can choose according to the requirements of quality when choosing a processing plant.

Based on the above factors, the charging standards of the PCB board processing plant will be very different. Generally speaking, the calculation method of quotation includes the following:

- Charged by the area of the board: Calculate according to the total area of the PCB board and the price of different boards. This is one of the most commonly used charges.

- Charges according to process requirements: Calculate according to the special process and quantity required by the customer.

- Charges at the quantity: Local offer according to the number of customer orders, the more the number, the lower the unit price.

- Charged at the delivery time: According to the delivery time and urgency required by the customer, you can charge an additional urgent fee.

- Charges according to special requirements: If customers have special requirements such as shock -proof and waterproof, processing plants will offer according to the specific situation.

In general, the charging standards of the PCB board processing plant in China are relatively flexible, and quoted according to the specific needs of customers and orders.

Therefore, when choosing a processing plant, customers need to compare and choose according to their actual needs to obtain the best price and quality assurance.

At the same time, customers need to express their needs and requirements clearly when communicating with processing plants in order to obtain accurate offer and production plans.

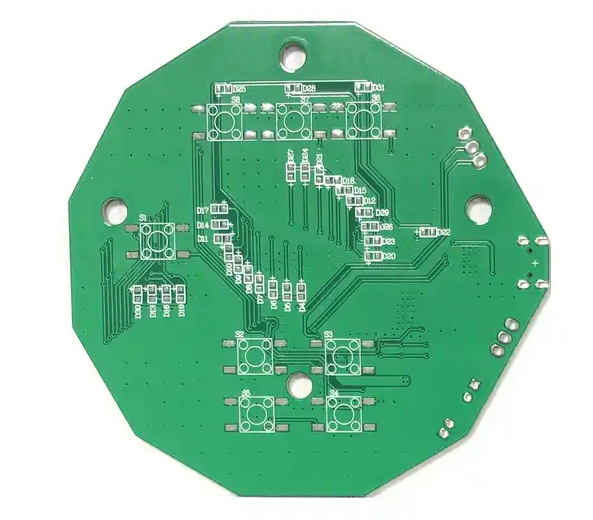

Fumax PCB factory

PCB factory is a place specializing in PCB (Printed Circuit Board) production and manufacturing.

As a key component of electronic products, PCB carries various electronic components and circuit networks and is an important foundation for realizing the functions of electronic equipment.

PCB factories convert raw materials into PCB products of different specifications and requirements through a series of processing processes to meet the needs of different industries and fields.

Features and advantages of Fumax PCB factory:

- Specialization and scale: PCB factories focus on the manufacturing and production of PCBs. They have specialized production equipment and processes, which can achieve large-scale production and improve production efficiency and product quality.

- Advanced technology: PCB factories use advanced manufacturing technologies, such as automated production lines, high-precision processing equipment, etc., to achieve high-precision and high-reliability PCB product manufacturing.

- Customized services: PCB factories can provide personalized customized services according to customer needs to meet different size, material, process and performance requirements.

- Quality Assurance: PCB factories focus on quality assurance and ensure product reliability and stability through strict quality control and testing methods to meet customer quality requirements.

- Fast delivery: PCB factories have fast delivery capabilities and can complete production and delivery in a timely manner according to customer time requirements to meet customers’ urgent needs.

When choosing a PCB factory, customers need to consider the factory’s scale, technical level, quality assurance, service capabilities and other aspects in order to choose a suitable partner and obtain high-quality PCB products and services.