The PCB assembly process of the LED display module includes screen printing solder paste on the PCB pads, solder paste inspection, placing SMD components, reflow soldering connection pins, and automatic optical inspection to ensure that there are no major problems.

During the assembly process, ensure that the pad direction of the LED is perpendicular to the stretching direction of the PCB to avoid breaking the gold wire and causing an open circuit, and bake the LED before assembly to prevent moisture from causing the glue to break and the light color to turn yellow.

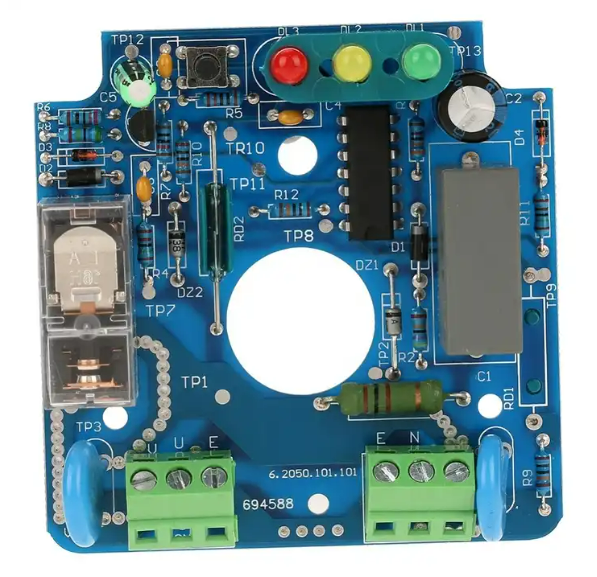

The LED display module PCB assembly process involves multiple complex steps. The following is a detailed introduction to this process:

Preparation for LED display module PCB assembly

- Clean the PCB: Use specific cleaning agents and equipment to clean the PCB to remove dirt and impurities on the surface to ensure its cleanliness.

- Check the LED lamp beads: Check the quality of the LED lamp beads to ensure that they are not damaged or defective.

- Prepare welding equipment: Prepare welding tools, solder, flux and other materials for subsequent welding work.

PCB processing and assembly

- PCB positioning and cutting: According to the design drawings, use a cutting machine or laser cutting equipment to accurately cut the PCB to ensure that its size and shape meet the requirements.

- Drilling and countersinking: Drill or countersink holes on the PCB as needed to facilitate the installation of LED lamp beads and other components.

- Print solder: Print an appropriate amount of solder on the PCB to ensure the soldering quality of the LED lamp beads.

- Place the LED lamp bead: Place the LED lamp bead at the designated position on the PCB, making sure its direction is correct.

- Welding LED lamp beads: Use welding equipment to weld the LED lamp beads on the PCB. Pay attention to temperature and time control during the welding process to ensure that the LED lamp beads will not be damaged.

LED display module PCB assembly testing and adjustment

- Preliminary test: After completing the PCB assembly, conduct a preliminary functional test to check whether the LED display module is working properly.

- Adjustment and correction: If there is a problem with the display module during testing, adjustment and correction are required. This may involve operations such as resoldering or replacing components.

- Aging test: Conduct a long-term, high-intensity aging test on the adjusted and calibrated display module to ensure its stability and reliability.

LED display module PCBA post-processing

- Cleaning and finishing: After testing and adjustment are completed, clean the display module for the final time to remove possible impurities and foreign matter.

- Protective treatment: Protect the surface of the display module, such as spraying moisture-proof, dust-proof, UV-proof and other coatings, to increase its service life and durability.

- Packaging and storage: Properly package the finished product for easy transportation and storage. At the same time, attention must be paid to controlling environmental factors such as temperature and humidity to ensure that the quality and performance of the display module are not affected.

- Shipping inspection: Conduct a final comprehensive inspection before shipment to ensure that the product meets quality requirements and customer requirements. At the same time, product quantity, specifications and other information need to be checked to ensure correct delivery.

- Customer training and technical support: Provide corresponding training and technical support according to customer needs to ensure that customers can use and maintain products correctly. At the same time, we need to pay attention to customer feedback and opinions and continuously improve the quality of products and services.

- Continuous improvement and optimization: Through monitoring and analysis of the production process, we will continue to discover existing problems and room for improvement, continue to optimize the process flow and management system, and improve production efficiency and product quality levels. At the same time, it is necessary to pay attention to industry dynamics and technological development trends, and timely introduce new technologies and new processes to improve product competitiveness.

- Environmental control: During the production process, attention should be paid to controlling environmental factors such as the temperature and humidity of the working environment to ensure that it meets process requirements and product quality standards. For production links that require special environmental conditions, corresponding equipment and facilities should be configured, such as clean rooms, constant temperature and humidity equipment, etc.

- Personnel training and safety: Provide necessary training to personnel involved in production to ensure that they are familiar with operating procedures, master relevant skills and safety knowledge. At the same time, necessary safety protection measures should be provided, such as wearing protective glasses, gloves, etc., to ensure the safety and health of personnel. For production links involving high-risk operations, safety management, training and education should be particularly strengthened.

- Documentation: Detailed documentation should be maintained throughout the entire production process, including production plans, process flows, test reports, etc. These records are very valuable for subsequent product maintenance and problem tracing. At the same time, relevant documents and materials should be organized and archived regularly to facilitate management and inquiry.

- Quality control and inspection: Establish a complete quality control and inspection system to ensure that the production quality of each link meets the requirements. For key production links and processes, quality control points should be set up and strictly monitored. At the same time, random inspections or full inspections of products should be carried out regularly to ensure the consistency and stability of product quality. Unqualified products should be processed and reworked in a timely manner to ensure that product quality meets customer requirements and market standards.