Automotive LED PCB manufacturing and production is a complex and rigorous process involving multiple links and considerations.

Below we explain the main manufacturing processes and precautions.

The detailed introduction of automotive LED PCB manufacturing and production is as follows:

design phase

Before starting manufacturing, the PCB design begins. The design process needs to consider aspects such as electrical performance, thermal design, mechanical strength and size. Design requirements strictly adhere to industry standards and customer specifications to ensure the reliability and performance of the final product.

1.1 Determine design specifications and standards

Before starting the design, it is necessary to clarify the design specifications and standards, such as IPC standards (Electronic Industry Association standards). These standards involve various aspects such as PCB size, layout, wiring, aperture, etc.

1.2 Schematic design and review

Conduct schematic design according to project requirements and specifications. After the design is completed, internal and customer reviews are conducted to ensure the correctness and feasibility of the schematic.

1.3 PCB layout and wiring design

Carry out PCB layout and wiring design based on the approved schematic diagram. Layout and wiring are key links in PCB manufacturing, and multiple aspects such as electrical performance, signal integrity, heat dissipation performance, and mechanical strength need to be considered.

1.4 Design review and revision

After the design is completed, a design review is conducted to ensure the correctness and feasibility of the design. Based on the review results, necessary corrections and optimizations are made.

Material procurement stage

After completing the design, purchase the raw materials and auxiliary materials required for PCB manufacturing according to the design requirements. These materials include copper clad laminates, copper foil, insulation materials, solder, etc. The quality and reliability of materials need to be ensured during the procurement process to meet the high quality and performance requirements of the automotive industry.

manufacturing stage

PCB manufacturing is a complex process involving multiple links and processes. Here is a brief description of some key processes:

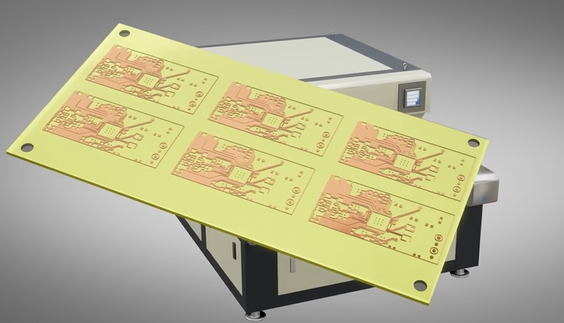

3.1 Copper clad laminate processing

The purchased copper clad laminate is cut, drilled and processed for subsequent circuit production.

3.2 Line production

Make circuits on copper-clad boards by chemical deposition or physical copper coating. This process involves multiple steps, such as surface treatment, circuit pre-treatment, electroplating, etc.

3.3 Solder mask application

After the circuit is completed, a solder mask is applied to protect the circuit from the outside environment. The application method and quality of solder mask have a significant impact on the reliability and performance of PCBs.

3.4 Character and mark printing

Print the necessary characters and markings on the PCB to identify circuits and components. The printing accuracy and clarity of these characters and marks need to meet certain requirements.

3.5 PCB quality inspection

After completing the PCB production, strict quality inspection is performed, including appearance inspection, dimensional measurement, performance testing, etc. Problems discovered during the inspection should be dealt with and corrected in a timely manner.

Assembly stage

After PCB manufacturing is completed, component assembly is performed. This process involves component mounting, welding, testing and other links. During the assembly process, it is necessary to ensure the accuracy and reliability of component placement to avoid problems such as incorrect installation and missing installation. The welding process needs to ensure welding quality and reliability of solder joints to ensure the electrical and mechanical properties of the final product. After the assembly is completed, necessary inspections and tests are performed to ensure that the quality and performance of the product meet the requirements.

Quality Assurance and Testing Phase

During the production process and after assembly, a series of quality assurance and testing work are required to ensure that the product’s reliability and performance meet standards. These tests include but are not limited to: appearance inspection, dimensional measurement, performance testing, environmental testing, etc. Quality assurance and testing are important links to ensure that products meet customer requirements, and are also important means to enhance corporate competitiveness.

Packaging and shipping stage

The final stage is the packaging and shipping stage. Proper packaging according to product characteristics and customer requirements to protect the product from damage during transportation. At the same time, reasonable packaging can also improve the added value and market competitiveness of products. After the product packaging is completed, safe and reliable transportation is carried out according to customer requirements to ensure that the product is delivered to customers on time.

Summarize

Automotive LED PCB manufacturing and production is a rigorous and complex process involving multiple links and considerations. From design to packaging and transportation, every link requires strict quality control and quality assurance.

With the continuous advancement of technology and changing market demands, automotive LED PCB manufacturing and production will continue to develop towards higher quality and higher efficiency.