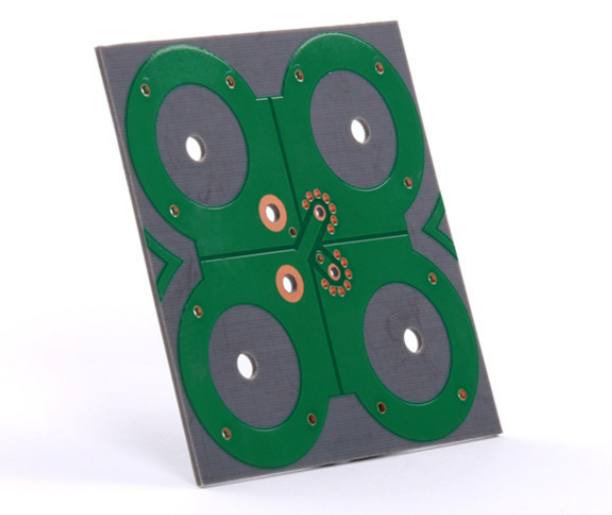

PCB high-frequency board materials for high-frequency device power dividers and couplers must have low dielectric constant, low loss tangent, and high thermal conductivity to ensure the stability of signal transmission and reduce energy loss.

At the same time, materials must also have excellent mechanical properties, chemical stability and environmental protection to meet long-term reliability requirements in complex environments.

High frequency PCB overview

At high and microwave frequencies, material properties have a particularly significant impact on circuit performance. For high-frequency devices such as power dividers and couplers, choosing the appropriate PCB high-frequency board material is the key to ensuring their performance. This article will introduce commonly used PCB high-frequency board materials and their characteristics.

Commonly used high frequency board materials

Polytetrafluoroethylene (PTFE):

- Advantages: low dielectric constant (εr≈2.1), low loss tangent (tanδ≈0.0003), high temperature resistance, good chemical stability, and excellent high-frequency performance.

- Applications: Commonly used where excellent high frequency performance and high stability are required, such as satellite communications and military applications.

Alumina (Al2O3):

- Advantages: high hardness, high thermal conductivity, good high-frequency insulation performance.

- Application: Suitable for high power, high frequency and occasions requiring high thermal stability.

Aluminum Nitride (AlN):

- Advantages: high thermal conductivity (about 200W/m·K), low dielectric constant (εr≈9), low thermal expansion coefficient.

- Application: Suitable for high frequency, high power and applications requiring high thermal conductivity and low thermal expansion coefficient.

Cyanate ester resin:

- Advantages: low dielectric constant (εr≈2.5-3.0), low thermal expansion coefficient, good high-frequency performance.

- Application: Suitable for high-speed digital signal transmission and microwave and millimeter wave components.

Ceramic materials such as alumina, aluminum nitride, silicon nitride, etc.

- Advantages: high thermal conductivity, low dielectric constant, low thermal expansion coefficient.

- Application: Suitable for high frequency, high power and occasions requiring high thermal conductivity and low thermal expansion coefficient, such as power dividers, couplers and other microwave devices.

Basis for choosing high frequency circuit boards

Selecting a suitable high-frequency board material requires comprehensive consideration of the following factors:

- Signal frequency and speed: High frequency and microwave signals have specific requirements on the dielectric constant and conductivity of materials. High-frequency signals require materials with low dielectric constant and low loss tangent to reduce signal loss and delay.

- Power Capacity: High power signals require materials with high thermal conductivity and high temperature resistance to prevent overheating and performance degradation.

- Mechanical stability: Some materials may deform under temperature changes or mechanical stress, affecting circuit performance. Therefore, materials with good mechanical stability need to be selected.

- Cost and Processability: On the premise of meeting performance requirements, cost and ease of processing are also important considerations. Although some high-performance materials have excellent performance, they are costly and difficult to process.

- Environmental factors: Some applications may need to work in harsh environments, such as high temperature, high humidity, corrosion, etc. At this time, the environmental resistance of the material becomes particularly important.

- Compatibility and Standardization: Considering the degree of compatibility and standardization with other systems, choosing materials that are already widely accepted and used can reduce risks and improve interoperability.

- Environmental protection and sustainability: Modern electronic manufacturing is paying more and more attention to environmental protection and sustainability, and choosing environmentally friendly and recyclable materials is the future trend.

- Technical Support and Supply Chain: Choosing materials with mature technical support and stable supply chain can ensure the smooth progress of production and maintenance.

- Future technology development considerations: Considering the trends and possibilities of future technology development, choosing new materials with potential technical advantages and development space may help maintain the competitiveness of products.

- Safety and Reliability: In some critical applications, such as military or aerospace fields, safety and reliability are the primary considerations, and materials with high reliability and safety factors need to be selected.

- Availability of design tools and simulation software: Modern PCB design increasingly relies on simulation tools for optimization and verification. Therefore, choosing materials that are widely accepted and supported by mature simulation software can speed up design and increase success rates.

- Industry Standards and Specifications: Different industries and application areas may have their own specific standards and specifications. Choosing materials that comply with these standards and specifications can ensure product compliance and interoperability.

- Ease of repair and maintenance: Considering the repair and maintenance needs during the product life cycle, choosing materials that are easy to replace and repair can reduce the total cost of ownership (TCO).