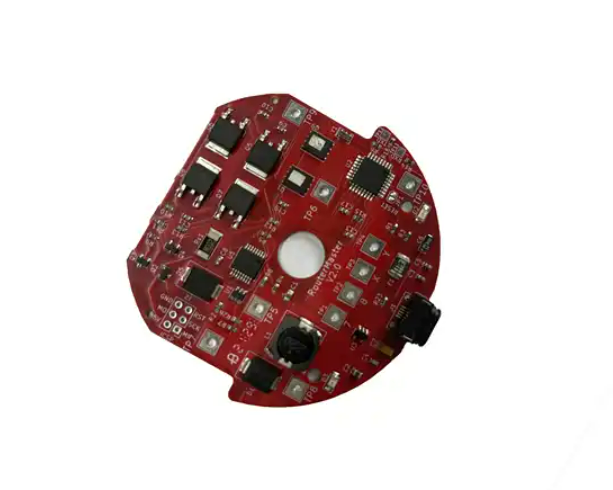

The smart Headphone PCB circuit design solution provides an efficient and reliable hardware platform, focusing on optimizing sound quality, noise reduction and battery life performance.

It uses advanced electronic components and layout technology to ensure stability and durability and meet the diversity and personality of smart headsets. needs.

Overview of Smart Headphone Circuit Design

Smart headphones are wireless audio devices that integrate multiple functions, including music playback, voice assistant control, noise cancellation, induction detection, etc.

In order to realize these functions, the PCB circuit design of smart headphones needs to meet the requirements of high performance, low power consumption, compactness and miniaturization. This program will elaborate on the PCB circuit design of smart headphones to ensure its quality and reliability.

Smart headset PCB design plan

- Chip selection

The core of smart headphones is the main control chip, which is responsible for processing audio data, controlling other peripherals, and communicating with devices such as mobile phones. Depending on performance and functionality requirements, choosing the right chip is critical. Mainstream chip suppliers include Qualcomm, MediaTek, Spreadtrum, etc. They provide a variety of chip solutions suitable for smart headsets. When selecting, factors such as the chip’s computing power, power consumption, integration level, and compatibility with peripherals need to be considered.

- Power management unit

The power management unit of the smart headset is responsible for providing a stable power supply to ensure the normal operation of each module. When designing the PCB, it is necessary to lay out the power modules reasonably and select appropriate power chips to achieve efficient and stable power supply. In addition, in order to extend the service life of the headset battery, the power management unit should have functions such as power detection and charging control.

- Audio processing module

The audio processing module is an important part of smart headphones. It is responsible for processing audio data, improving sound quality, and implementing noise reduction functions. The audio processing module generally consists of a digital signal processor (DSP), amplifier, filter, etc. When designing PCB, it is necessary to ensure the transmission quality of audio signals and reduce interference and distortion. In addition, the interface design between the audio processing module and the main control chip also needs to be considered to ensure the stability and real-time nature of data transmission.

- Wireless communication module

Smart headphones require wireless communication with devices such as mobile phones to achieve remote control and data transmission. Wireless communication modules generally use Bluetooth or Wi-Fi technology. When designing the PCB, it is necessary to reasonably lay out the antenna positions to improve signal reception sensitivity. At the same time, the interface design between the wireless communication module and the main control chip also needs to be considered to ensure the reliability and stability of data transmission.

- Sensor module

Smart headphones are usually equipped with a variety of sensors, such as accelerometers, gyroscopes, light sensors, etc., to achieve functions such as motion detection and wear detection. When designing the PCB, sufficient space needs to be reserved for the sensor module to ensure its normal installation and operation. At the same time, the interface design between the sensor module and the main control chip also needs to be considered to achieve data collection and transmission.

- Human-computer interaction module

The human-computer interaction module is an important part of the smart headset, which includes microphones, speakers, LED indicators and other components. When designing PCB, it is necessary to ensure that the layout of human-computer interaction modules is reasonable and convenient for users to use. At the same time, it is also necessary to consider the design of noise reduction technology, audio equalization processing, etc. to improve user experience.

- Production process and quality control

In order to ensure the quality and reliability of smart headphones, production technology and quality control are also crucial links. In the PCB design stage, the feasibility of the production process and the reliability of quality control need to be considered. Select appropriate components and processes, and strictly control quality standards and quality inspections during the production process to ensure the quality and performance of the final product.

- Later optimization and maintenance

After completing the preliminary PCB design, post-stage optimization and maintenance work still needs to be performed. Based on the problems encountered during actual production and testing, the PCB design is improved and optimized to improve production efficiency and product quality. At the same time, corresponding maintenance plans and spare parts inventory plans need to be developed to ensure the stability and reliability of the product during use.

Smart headset PCB circuit design summary

The PCB circuit design of smart headphones is a complex and meticulous process, which requires comprehensive consideration of performance, power consumption, miniaturization and other requirements. The quality and reliability of smart headphones can be ensured through reasonable considerations in chip selection, power management, audio processing, wireless communication, sensor module design, production process and quality control. At the same time, later optimization and maintenance are also crucial links, which can improve production efficiency and product quality and reduce maintenance costs.

Fumax smart headphone PCB circuit design OEM factory

The smart headset PCB circuit design OEM factory focuses on providing high-quality, high-reliability smart headset PCB circuit design and manufacturing services to global customers.

We have advanced production equipment and a professional technical team, and strictly follow international quality standards to ensure that the quality and performance of each product reaches the highest level.

At the same time, we are committed to working closely with our customers to provide customized solutions to meet different needs. By choosing us, you will get reliable and efficient smart headset PCB circuit design OEM services, and jointly create a bright future for smart audio equipment.