Flexible PCB manufacturing material selection for temperature and humidity sensor modules

Temperature and humidity sensor module is a device used to measure temperature and humidity. It usually consists of a sensor and a circuit and can be connected to a computer or microcontroller for data collection and monitoring.

- Flexible PCB manufacturing material selection for temperature and humidity sensor modules

- Flexible PCB for temperature and humidity sensor?

- What are the specific functions of flexible PCB in temperature and humidity sensors?

- How does flexible PCB realize signal transmission?

- Is there any application in other devices using flexible PCB for signal transmission?

- PCB manufacturing material suppliers in China

This kind of module usually has the characteristics of small size, low power consumption, high precision and high reliability, and is widely used in various fields, such as industrial automation, environmental monitoring, meteorological observation, etc.

When selecting a temperature and humidity sensor module, factors such as its measurement range, accuracy, interface type, size, and price need to be considered. At the same time, it is also necessary to select appropriate sensor modules based on actual application scenarios to ensure the accuracy and reliability of measurement results.

For example, the DHT11 digital temperature and humidity sensor is a temperature and humidity composite sensor with calibrated digital signal output, including a resistive humidity sensing element and an NTC temperature measuring element, and is connected to a high-performance 8-bit microcontroller with excellent quality. , ultra-fast response speed, strong anti-interference ability, high cost performance and so on.

In short, choosing a suitable temperature and humidity sensor module requires considering actual needs and application scenarios to ensure the accuracy and reliability of measurement results.

Flexible PCB for temperature and humidity sensor?

Yes, temperature and humidity sensors can use flexible PCB. Flexible PCB has the advantages of light weight, small size, bendability, and foldability, so it can play an important role in sensor manufacturing.

In temperature and humidity sensors, flexible PCBs can be used to connect the sensor elements and circuit boards together to form a complete sensor module. Since flexible PCB can accommodate sensor elements of various shapes and sizes, multiple sensor elements can be easily integrated onto the same PCB, making the entire sensor module more compact and efficient.

In addition, flexible PCB can also improve the reliability and stability of the sensor. Because flexible PCB has good mechanical and electrical properties, it can ensure that the sensor can work normally under various environmental conditions and provide accurate measurement results.

In short, flexible PCB plays an important role in temperature and humidity sensors, which can improve the performance and reliability of the sensor and make the entire sensor module more compact and efficient.

What are the specific functions of flexible PCB in temperature and humidity sensors?

In temperature and humidity sensors, flexible PCB has the following functions:

Provide reliable support

As the substrate of the sensor module, the flexible PCB provides reliable support for the sensor components and circuits, ensuring the stability and durability of the sensor module.

Realize signal transmission

Wires can be laid on the flexible PCB to transmit the electrical signals output by the sensor elements to the processing circuit to realize signal collection and transmission.

Protect sensor components

Flexible PCB can protect sensor components from mechanical damage and environmental factors, extending the service life of the sensor.

Improve measurement accuracy

Flexible PCB can provide a stable signal transmission path, reduce signal interference and errors, thereby improving measurement accuracy.

Simplify the manufacturing process

Flexible PCB is easy to bend and fold, making the sensor module manufacturing process simpler, more efficient and more flexible.

In short, flexible PCB plays an important role in temperature and humidity sensors, which can improve the performance and reliability of the sensor and make the entire sensor module more compact and efficient.

How does flexible PCB realize signal transmission?

In temperature and humidity sensors, flexible PCB implements signal transmission in the following ways:

- Wire routing: Wires can be laid on the flexible PCB to transmit the electrical signals output by the sensor elements to the processing circuit. The layout of wires can be flexibly designed according to actual needs, and can be in straight lines, curves, or broken lines to achieve effective signal transmission.

- Signal transmission channel: Flexible PCB can provide a stable signal transmission channel and establish a reliable signal transmission path from the sensor element to the processing circuit. In this way, when the sensor element senses changes in environmental parameters, the output electrical signal can be transmitted to the processing circuit through the wires on the flexible PCB to realize signal collection and transmission.

- Anti-interference design: In order to improve the stability and accuracy of signal transmission, flexible PCB can adopt anti-interference design, such as setting up shielding layers, isolation bands and other measures to reduce the impact of external interference on the signal.

- Connection interface: Flexible PCB can provide standard connection interfaces, such as plugs, sockets, etc., which are used to connect the sensor module to the processing circuit or host computer and other equipment to realize signal transmission and processing.

In short, the flexible PCB realizes signal transmission in the temperature and humidity sensor by laying out wires, establishing a stable signal transmission channel, adopting anti-interference design and providing connection interfaces. These measures can improve the reliability and stability of the sensor module and make the entire sensor module more compact and efficient.

Is there any application in other devices using flexible PCB for signal transmission?

Yes, flexible PCBs for signal transmission are also used in other devices. Because flexible PCB has the advantages of light weight, small size, bendability, and foldability, it can be applied in many fields.

For example, in medical equipment, flexible PCB can be used to manufacture wearable medical equipment, such as smart bracelets, smart watches, etc. These devices need to implement functions such as signal transmission and data processing.

Flexible PCB can provide reliable signal transmission paths and stable circuit support, and can also adapt to the bending and folding requirements of the human body.

In addition, in the field of automotive electronics, flexible PCB can also be widely used. Various sensors and actuators need to be connected inside the car. Flexible PCB can provide flexible connection methods, adapt to the complex environment inside the car, and enable efficient signal transmission and processing.

In short, flexible PCBs for signal transmission also have broad application prospects in other devices, especially in fields that require flexible connections and reliable signal transmission.

PCB manufacturing material suppliers in China

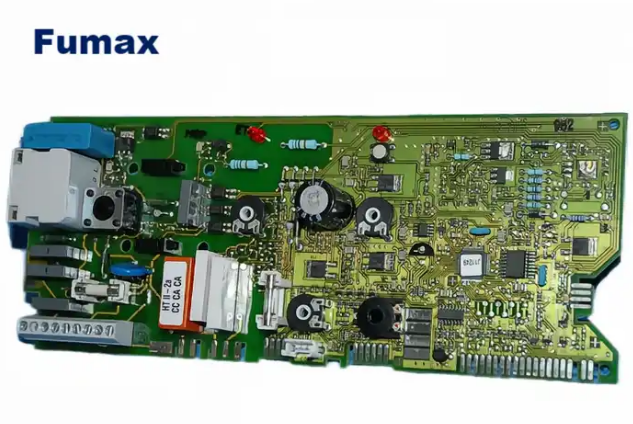

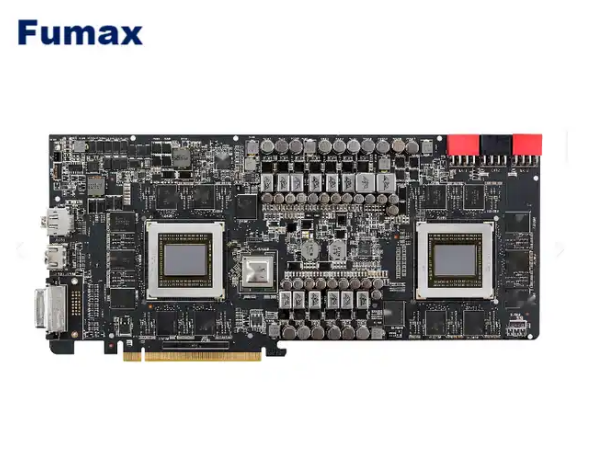

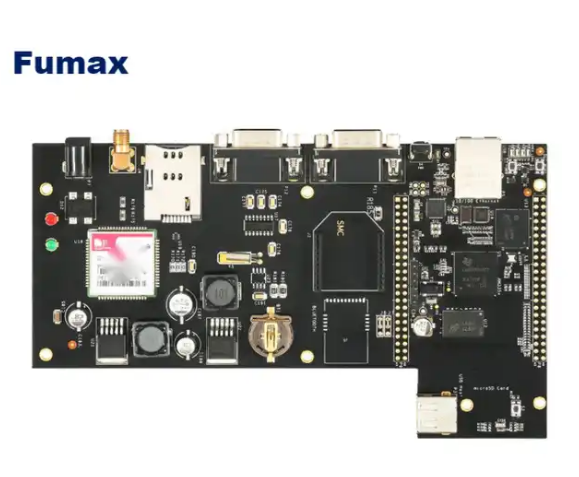

Shenzhen Fumax Technology Co., Ltd. focuses on one-stop services such as prototype PCB manufacturing, PCB assembly, circuit board PCBA design and custom development, software programming, component procurement, SMT patching, assembly testing and painting. A series of services from raw material procurement to production and testing.