The investment in opening an LED PCB assembly factory in Brazil involves many aspects, and the specific investment amount depends on many factors.

How much investment does it take to open an LED PCB assembly factory in Brazil?

Here are some key factors and corresponding investment needs:

- Factory construction: First, you need to find a suitable site to build a factory, which may involve leasing or purchasing land, building construction or modification costs, etc. In addition, the internal layout of the factory and the design of the production line also need to be considered, which will affect production efficiency and cost control. Estimated investment: US$1 million to US$3 million, depending on the size of the factory and the sophistication of the facilities.

- Equipment purchase: LED PCB assembly requires specific equipment and tools, such as PCB placement machines, welding equipment, testing equipment, etc. The cost of these devices ranges from thousands to hundreds of thousands of dollars, depending on the degree of automation and production capabilities of the equipment. Estimated investment: $500,000 to $2 million, depending on equipment selection and configuration.

- Raw material procurement: The raw materials required for LED PCB assembly include LED lamp beads, PCB boards, electronic components, etc. The procurement cost of these raw materials is related to product type, quality requirements and quantity. Estimated investment amount: depending on the type of raw materials and demand, usually hundreds of thousands of dollars.

- Employee recruitment and training: LED PCB assembly factories need to hire employees with professional skills, including technical workers, quality inspection personnel, management personnel, etc. Recruiting and training employees requires a certain amount of time and capital investment, as well as employee salary and benefit expenses. Estimated investment: Depending on the number of employees and their positions, typically in the hundreds of thousands of dollars.

- Quality assurance and certification: In the Brazilian market, product quality and safety certification are very important. You need to ensure that your factory’s production processes comply with relevant standards and regulations, which may require additional costs. Estimated investment: Depending on product and certification requirements, typically in the hundreds of thousands of dollars.

- Market development and marketing: In order to promote your products in the Brazilian market, you need to invest a certain amount of money in market development and marketing activities, such as advertising, participating in exhibitions, etc. Estimated investment amount: Based on market development plan and marketing budget, usually hundreds of thousands of dollars.

To sum up, the investment to open an LED PCB assembly factory in Brazil ranges from several million to tens of millions of yuan.

The specific investment amount will depend on your factory size, equipment configuration, market positioning and other factors. different.

In addition, it should be noted that in addition to the initial investment, ongoing investment in factory operations also needs to be considered, such as equipment maintenance, raw material procurement, employee compensation, etc. Therefore, it is recommended to fully consider various factors when formulating investment plans to ensure the rationality and sustainability of the investment.

Opening an LED PCB assembly factory in Brazil

Opening an LED PCB assembly factory in Brazil is a potential business decision. The growing demand for high-quality, low-cost LED products in the Brazilian market provides broad development space for this industry. The following is a detailed introduction to opening such a factory:

- Market analysis: First of all, it is necessary to conduct in-depth research on the Brazilian LED market to understand the demand, competition situation and target customer groups. By analyzing market needs and trends, more targeted marketing strategies and product positioning can be developed.

- Site selection and factory construction: Choosing a suitable factory site is crucial, taking into account proximity to suppliers, customers and transportation convenience. In addition, labor and operating costs in Brazil are also key factors. Consider building a factory in an industrial park where you may get more convenience and support.

- Supply chain management: Establish long-term cooperative relationships with reliable suppliers to ensure the quality and supply stability of raw materials. Considering the logistics costs in Brazil, working with suppliers that are within easy reach will help reduce shipping costs and time.

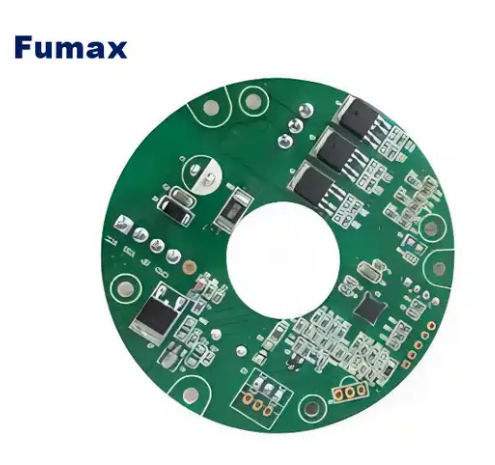

- Assembly process and equipment: Select appropriate assembly process and equipment according to product requirements. It may be necessary to invest in automated production lines to improve production efficiency and product quality. At the same time, ensure compliance with local environmental regulations and use environmentally friendly materials and processes.

- Quality and certification: Ensure that products comply with international quality standards, such as ISO 9001, etc. Quality is a key factor in winning customers’ trust. In addition, according to the requirements of the target market, obtain relevant product certifications, such as CE, UL, etc.

- Marketing and Sales: Develop effective marketing strategies and utilize online and offline channels to promote products. Build a strong sales network and establish cooperative relationships with local dealers or direct customers. Attending industry trade shows is a great opportunity to showcase your products and meet potential customers.

- Human Resource Management: Recruiting and training an efficient, professional team in Brazil is key. Provide a good working environment and benefits to attract and retain outstanding talents. Provide regular training and development opportunities to employees to improve overall team quality.

- Financial management and capital raising: Develop a detailed financial plan to forecast initial investment, operating costs, sales and return period. Consider raising funds through bank loans, partnerships or investors. At the same time, maintain good relationships with financial institutions to respond to possible funding needs.

- Compliance with laws and regulations: Understand and comply with Brazilian regulations on business registration, taxation, labor laws, etc. It is recommended to hire a professional lawyer or consultant to provide legal advice and support.

- Continuous improvement and innovation: Pay attention to industry dynamics and technological development, and continuously improve production processes and product innovation. Through R&D and market research, we continuously meet customer needs and maintain competitive advantages.

In short, opening an LED PCB assembly factory in Brazil requires comprehensive consideration of many aspects, including market analysis, supply chain management, quality assurance, marketing strategy, etc. With careful planning and execution, you will be able to succeed in this market of opportunity.

PCB factories serving Brazil

Shenzhen Fumax Technology Co., Ltd. was established in 2007 and is headquartered in Shenzhen, China. Focusing on one-stop services such as circuit board PCBA design customization and development, SMT patching, DIP welding, PCB assembly testing, painting, software programming, component procurement, etc. It has a complete product quality inspection process.