The projector PCB board has high customization requirements and needs to meet the comprehensive requirements of high performance, high reliability and low cost to ensure that it can provide power and signal transmission for the projector stably and reliably.

Introduction

With the continuous development of technology, projectors have become a common electronic device in modern homes and commercial places.

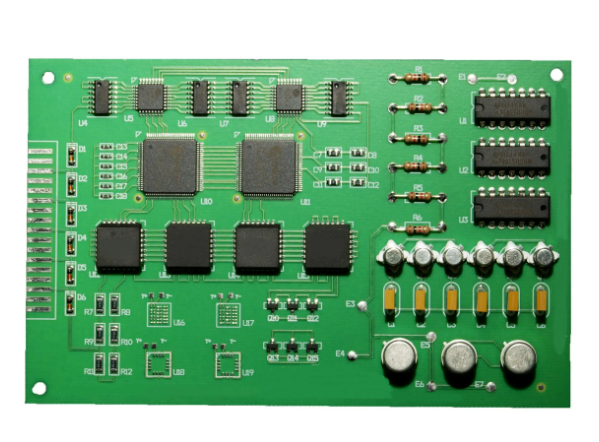

As one of the core components of the projector, the PCB board (printed circuit board) carries various electronic components to realize signal transmission and control functions.

In order to meet different application requirements, projector PCB boards often need to be customized. This article will explain in detail the requirements for projector PCB board customization.

PCB board selection

- Heat resistance: The projector will generate a lot of heat when working. Therefore, the PCB board should have good heat resistance and be able to withstand high temperature environments. Commonly used PCB boards with good heat resistance include polyimide, BT materials, etc.

- Insulation: The electronic components on the PCB board will generate electrical signals when working, which requires the PCB board to have good insulation properties to ensure the safe operation of the circuit.

- Mechanical strength: PCB boards need to have a certain mechanical strength to withstand external forces and ensure the stability and reliability of electronic components.

PCB layout design

- Arrangement of components: According to the circuit function and signal flow, the positions of electronic components should be reasonably arranged to ensure the stability and reliability of signal transmission. At the same time, the production process and assembly difficulty should be considered to minimize production difficulty and assembly costs.

- Routing design: Reasonably plan the routing of the PCB board to avoid interference and delay during signal transmission. In the wiring design, the “equal length principle” should be followed to keep the line length consistent and reduce loss and delay during signal transmission.

- Heat dissipation design: Considering the heat generated by the projector when working, a reasonable heat dissipation path needs to be designed on the PCB board. The heat dissipation effect can be improved by adding heat dissipation holes and optimizing the arrangement of components.

PCB manufacturability and reliability

- Processing accuracy: Customized PCB boards need to have high processing accuracy to meet the assembly requirements of electronic components. At the same time, parameters such as the warpage and surface roughness of the PCB board should be taken into consideration to ensure the stability and reliability of production.

- Reliability test: After the production of the customized PCB board is completed, a series of reliability tests, such as temperature cycle test, vibration test, salt spray test, etc., need to be carried out to ensure that it can work stably and reliably in actual use.

- Standardized design: Follow internationally accepted PCB design standards, such as IPC standards, to ensure the reliability and maintainability of the design. At the same time, the possibility of future product upgrades should be taken into consideration and a certain design margin should be reserved.

Cost and delivery time

- Cost control: On the premise of meeting performance requirements, try to reduce the cost of customized PCB boards. Cost control can be achieved by selecting appropriate board materials, optimizing component arrangement, and reducing unnecessary processes.

- Delivery time control: During the production process of customized PCB boards, the production plan should be reasonably arranged to ensure on-time delivery. At the same time, close communication should be maintained with suppliers to solve problems in the production process in a timely manner to ensure the smooth progress of production.

Summarize

Customizing projector PCB boards requires comprehensive consideration of many aspects, including material selection, layout design, manufacturability and reliability, cost and delivery time, etc.

When selecting appropriate materials and layout design, attention should be paid to aspects such as heat resistance, insulation, and mechanical strength; when considering manufacturability and reliability, attention should be paid to processing accuracy, reliability testing, and standardized design; in terms of cost, In terms of control and delivery time control, optimized design and management should be used to ensure that production tasks are completed on time and with high quality.

Only by comprehensively considering these factors and planning appropriately can a high-quality, high-performance projector PCB board be customized.