High-frequency copper-clad laminates have high technical content, which is mainly reflected in the comprehensive application of special material selection, precision manufacturing technology, surface treatment technology and electrical performance testing.

The use of these technologies can ensure low loss and high stability of high-frequency signals during transmission, which is a key factor in achieving high-speed signal transmission.

The main technical content of high-frequency and high-speed copper clad laminates

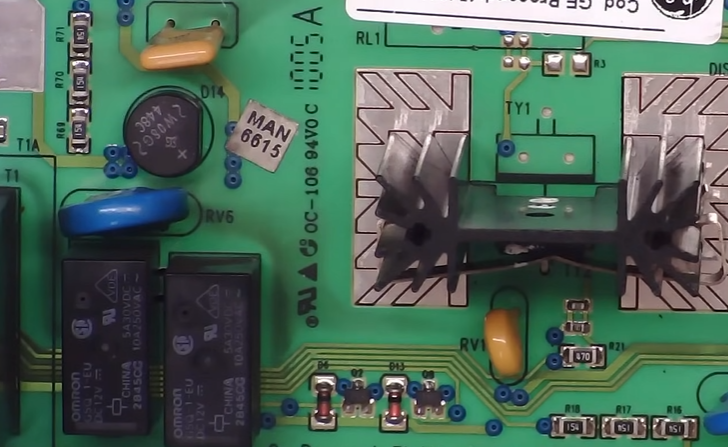

- Material selection: High-frequency and high-speed copper-clad laminates require the use of special materials, such as resins with low dielectric constant, low loss, and high insulation performance, to ensure the stability and low loss of signal transmission. In addition, high-performance copper foil is required to improve conductivity and stability.

- Manufacturing process: The manufacturing process of high-frequency and high-speed copper clad laminates is relatively complex and requires multiple steps, such as copper foil processing, resin coating, hot pressing, grinding, etc. These processes require precise control to ensure the performance and stability of the final product.

- Surface treatment: In order to improve the electrical performance and stability of high-frequency and high-speed copper clad laminates, surface treatment is required, such as gold plating, chemical silver, etc. These processing methods require precise control to ensure the performance and stability of the final product.

- Testing and evaluation: High-frequency and high-speed copper-clad laminates need to undergo a series of tests and evaluations, such as dielectric constant, loss factor, heat resistance, mechanical properties, etc. These tests and evaluations require the use of professional equipment and testing methods to ensure the performance and stability of the final product.

To sum up, high-frequency and high-speed copper-clad laminates have a high technical content and require the use of special materials and process technologies, as well as precise testing and evaluation. Therefore, only companies with higher technical level and accumulated experience can produce high-quality high-frequency and high-speed copper clad laminates.

At the same time, with the rapid development of 5G communications, Internet of Things and other fields, the application prospects of high-frequency and high-speed copper clad laminates will be broader, and market demand will continue to grow.

Frequently Asked Questions

The technical content of high-frequency copper-clad laminates is mainly reflected in aspects such as material selection, manufacturing process, surface treatment, and testing and evaluation. These aspects require a high level of technology and experience accumulation to ensure the performance and stability of the final product.

High-frequency copper-clad laminates require special materials, mainly because the transmission speed of high-frequency signals is faster and the requirements for electrical performance are higher. In order to reduce the loss and interference during signal transmission, special materials such as resin with low dielectric constant, low loss, and high insulation performance need to be used to improve the signal transmission quality and stability.

The manufacturing process of high-frequency copper-clad laminates is relatively complex and requires precise control. Common manufacturing processes include copper foil processing, resin coating, hot pressing, grinding, etc. These processes need to be selected and optimized based on specific materials and requirements to ensure the performance and stability of the final product.

Surface treatment methods for high-frequency copper-clad laminates include gold plating, chemical silver, etc. These processing methods can improve the electrical performance and stability of the product, but also require precise control to ensure the performance and quality of the final product.

High-frequency copper-clad laminates require a series of tests and evaluations, including dielectric constant, loss factor, heat resistance, mechanical properties, etc. These tests and evaluations require the use of professional equipment and testing methods to ensure the performance and stability of the final product.

With the rapid development of 5G communications, Internet of Things and other fields, the market prospects of high-frequency copper clad laminates are very broad. In the future, with the continuous advancement of technology and the increase in application demand, the market demand for high-frequency copper clad laminates will also continue to grow.