The effect of GPU accelerator cards on PCB performance is a complex topic, involving knowledge in multiple fields, including computer hardware, graphics processing, algorithm acceleration, etc.

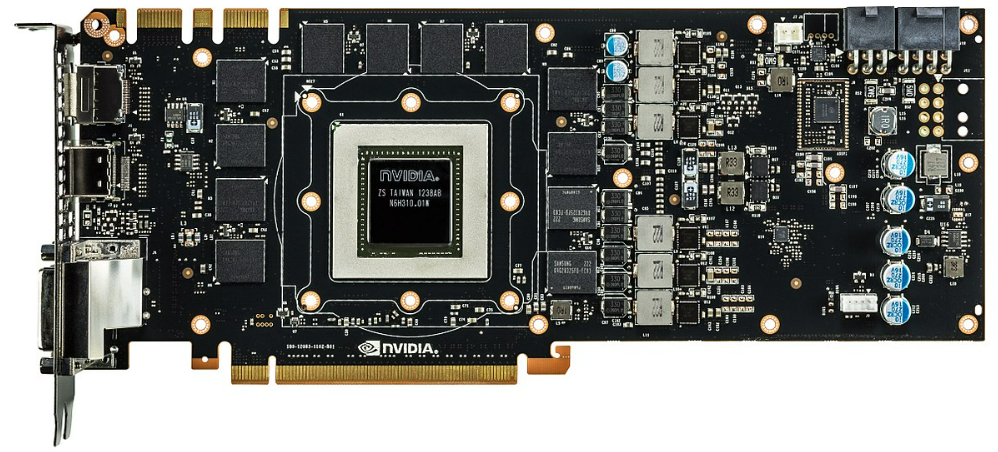

Before we delve into it, we first need to clarify the definition and functions of a GPU accelerator card. A GPU accelerator card, or graphics processing unit accelerator card, is a specialized hardware device designed to handle graphics rendering and other computationally intensive tasks.

In recent years, with the development of deep learning and other computing technologies, the functions of GPU accelerator cards have expanded to a wider range of fields, including scientific computing, data analysis, artificial intelligence, etc.

Next, we discuss the role of GPU accelerator cards on PCB performance in further detail.

- High Computing Performance: The core advantage of the GPU accelerator card lies in its powerful computing power. Through a highly optimized parallel computing architecture, GPU can quickly process large-scale data sets, greatly improving PCB performance. In terms of high-speed digital signal processing and complex algorithm operations, GPU accelerator cards can significantly reduce computing time and improve overall system performance.

- Low power consumption design: With the increasing awareness of environmental protection and rising energy costs, the energy consumption of equipment has become a key performance indicator. GPU accelerator cards usually adopt low-power designs, which help reduce PCB heat generation and power consumption requirements, making the system more energy-saving and efficient.

- Optimize the heat dissipation system: Since the GPU accelerator card generates a lot of heat when processing tasks, a good heat dissipation system is the key to ensuring its stable operation. Optimized PCB design and layout can help better dissipate heat, extend the service life of the GPU accelerator card, and ensure continued high-performance performance of the system.

- Scalability: As technology continues to advance, new GPU accelerator cards may continue to emerge. A properly designed PCB should have good scalability, allowing the GPU accelerator card to be upgraded or replaced in the future, thereby maintaining the advancement and performance of the system.

- Signal Integrity: In the process of high-speed data transmission, signal integrity and stability are crucial. Excellent PCB design can ensure the quality and reliability of data transmission between the GPU accelerator card and other components, reducing signal distortion and delay.

- Wiring and Layout: Proper wiring and component placement are crucial to PCB performance. Taking into account the special needs of GPU accelerator cards (such as high current, high voltage, etc.), proper wiring and layout can ensure stable power supply, reduce electromagnetic interference (EMI), and improve overall reliability.

- Modular design: The modular design of the GPU accelerator card and other key components helps simplify the system maintenance and upgrade process. The modular design also reduces the coupling between different modules and improves the stability and scalability of the system.

- Cost and Manufacturability: While meeting performance requirements, PCB cost and manufacturability are also important considerations. Selecting appropriate materials, optimizing process flow, and rational design layout can help reduce costs and improve production efficiency.

- Compatibility and Standardization: To ensure compatibility with existing systems and future technologies, PCBs should follow industry standards and specifications. This not only helps reduce R&D costs, but also promotes widespread product application and market acceptance.

- Safety and Reliability: The safety and reliability of PCB should be fully considered during the design and manufacturing process. This includes, but is not limited to, electrical safety, mechanical strength, environmental adaptability, and fault detection and recovery mechanisms.

- Maintainability: Considering the long-term operation and maintenance of the system, the PCB should be designed to facilitate repair and replacement of components. This includes easy-to-access interfaces, clear labeling, and appropriate repair documentation.

- Environmental Friendliness: With the increasing emphasis on sustainable development, the design of PCB and GPU accelerator cards should also consider environmental impact. This includes using environmentally friendly materials, optimizing energy consumption and reducing waste generation.

- Reliability Test: During the production process, strict reliability testing should be conducted to ensure the performance and stability of the PCB and GPU accelerator card. This includes, but is not limited to, environmental testing, stress testing, and life testing.

- Technical updates and iterations: Due to the continuous advancement of technology, the design of PCB and GPU accelerator cards should be forward-looking to adapt to future technology upgrades and iterations. This may involve considerations such as design flexibility, scalability and upgrade paths.

- User-friendliness: In addition to technical performance, user experience is also an important factor in evaluating PCB performance. The design should be easy to use, intuitive, and ergonomic to increase user productivity.

- Safety considerations: During the design and manufacturing process, the safety of PCB should be fully considered. This includes aspects such as electrical safety, mechanical safety, and data security. Ensure that the system can operate safely and stably under various circumstances.

- Cost-Benefit Analysis: When designing and manufacturing PCBs, a comprehensive cost analysis should be performed. This includes material costs, manufacturing costs, maintenance costs, and potential long-term operating costs. Through sound cost-benefit analysis, you can ensure that the product is economically viable and competitive.

- Documentation and Technical Support: In order to facilitate user use and maintenance, complete documentation and technical support should be provided. This includes user manuals, installation guides, operating instructions, troubleshooting guides, etc. At the same time, providing timely technical support is also crucial to improving user experience and system reliability.

By comprehensively considering the above factors, we can design and manufacture PCB products with excellent performance, reliability and stability, while meeting the needs of various practical applications. In the ever-evolving technology field, continuous optimization and innovation will be the key to ensuring the performance of PCB and GPU accelerator cards.